Catalog excerpts

High Speed Linear Die Sinker EDM

Open the catalog to page 1

The World's First 10-Year Positioning Accuracy Guarantee Utilising the linear motor drive system, Sodick die-sinker EDMs and wire-cut EDMs have enabled difcult machining operations that were not possible with conventional ball screw-type EDMs, resulting in the cumulative shipment of more than 24,000 units by early 2010. The linear motor-driven EDM, eliminates the need for ball screws and allows for non-contact motion. Use of the Linear Motor removes the deterioration in machining accuracy caused by the worn ball screw assemblies throughout the machine life. Sodick’s condence in the...

Open the catalog to page 2

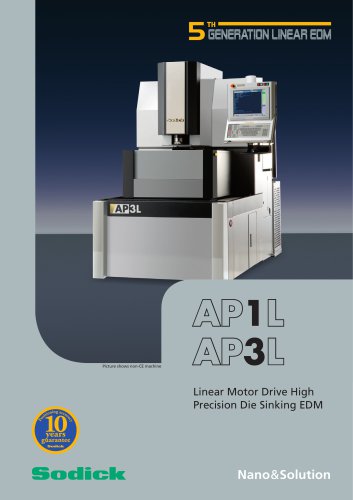

The 5th Generation Linear EDM Technology Has Arrived Since the launch of the world’s rst linear EDM machines in 1999, Sodick has constantly improved and further developed this unique technology. With over 36,000 machines installed around the world, this latest series of EDM machines represents the 5th generation of Sodick linear technologies. 10 years of linear EDM experience and know-how at your nger tips. 3

Open the catalog to page 3

Core Technology Five Core Technologies Developed In-House For Achieving The World's Highest Quality Machining Starting with the development of electrical discharge circuits, Sodick has continued to make untiring efforts in the research and development of advanced EDMs. Sodick’s philosophy has been the pursuit of the highest level of accuracy, speed and versatility of machining in order to provide the highest quality products to its customers. Sodick's: Power Supply Units, Discharge Units, Linear Motors, Motion Controllers and Fine Ceramic Components have evolved as its ve core technologies....

Open the catalog to page 4

Ceramic Components In major components, such as quill and table, the Sodick Die Sinker EDM series is equipped with in-house made ceramic material, which has been carefully researched and is considered as the best material for use in highend EDM machines. Advantages Of Ceramic Material 1) When it is used in moving components, such as the quill, the low density is effective in weight reduction, leading to increased dynamic response, resulting in superior machined surface quality. Dynamic brake 2) The low co-efcient of linear thermal expansion minimises the thermal deformation caused by...

Open the catalog to page 5

Advantages of Linear Motor Drive System No Flushing Operations Linear motor-based machining (without flushing) The linear motor drive mechanism generates an ultra high-speed pumping effect efciently removing chips, gas and carbon which exist between the electrode and the work piece. Therefore, machining can be performed without the need for ushing. RAPID JUMP Highly Rigid Linear Guide In order to ensure very accurate straight motion in each axis, highquality linear rails are used. These rails are xed in position on manually scraped surfaces for optimum accuracy. RAPID DOWN The rapid upward...

Open the catalog to page 7

LN Professional LN Professional Maximises The Capability Of Linear Motors A Wide Variety Of Applicable Machining Patterns LN Professional offers a wide range of applicable cutting patterns to respond to various kinds of machining needs. For each machining pattern, optimum machining conditions and axis motions are available. Different kinds of machining can be performed through simple operations without depending on operator's skill and experience. If the core pin pattern is selected, for example, it automatically shows the most suitable machining conditions and axis motions required. The LN...

Open the catalog to page 8

User-Friendly Graphic Display The graphic display shows multiple-piece cutting positions in an easy to understand manner. Also, the plane or co-ordinate system to be displayed can be designated. The graphic can be converted into the machine co-ordinate system to allow for checking the correlation of

Open the catalog to page 9

Machining Samples Speaker Rib Electrode Workpiece Machining Depth Machining Time Surface finish Electrode Wear Automotive Part with only one electrode Electrode Workpiece Machining Depth Machining Time Surface finish Punch Marking Electrode Workpiece Machining Time Surface finish Electrode Undersize Copper STAVAX 1 h 30 min 0.45 µmRa 0.018 mm Electrode Workpiece Machining Depth Machining Time Surface finish Electrode Wear Helical Gear Cutting Electrode Workpiece Machining Depth Machining Time Surface finish

Open the catalog to page 10

Standard Features “SGF” Nano- Wear Discharge Unit The new “LN2” series power supply unit is equipped with the “SGF Plus” discharge unit. ”SGF Plus” minimises graphite electrode wear and maximises cutting speed offering the highest performance level possible, which allows “Nano” wear machining. The “SGF Plus” circuit achieves roughing to nishing using only a single graphite electrode. This eliminates the requirement for multiple electrodes, and therefore reduces manufacturing time. Another Sodick innovation is made possible by the use of linear motor. Electrode Graphite (TTK9: TOYO TANSO)...

Open the catalog to page 11

Options High Precision Rotary Head, C axis The Sodick Rotary Head (C axis) “SEC10” offers 1/1,000,000 of standard resolution. It enables high precision indexing with direct-drive and continuous rotation (20rpm), expanding the machining capabilities. SCR-72P, the rotary head with higher rotation speed of up to 2,000rpm (resolution of 1/720,000) is also available. SEC-10 Resolution Max. spindle speed Max. current Flushing through Axis Shuttle ATC A linear electrode changer is available on the AG range of machines. This allows multi-electrode operations to be achieved in unattended mode. As...

Open the catalog to page 12

8-axis Simultaneous Technology Sodick has always developed their own controls and this has allowed the company to develop, an 8-axis simultaneous control. No other EDM manufacturers are able to offer this feature. Multi axis EDM machining is mainly used in the aerospace and medical industries but also can be used for part manufacture. The capability to clamp the workpiece once and then execute complex operation enhances productivity and accuracy. Automation System Thanks to the automatic 3-sided drop tank, access for automation is made easy. The installation of a robot on either side of the...

Open the catalog to page 13All Sodick catalogs and technical brochures

-

ALC Series

24 Pages

-

Linear Product Range 2019

28 Pages

-

HS430L

2 Pages

-

HS650L

2 Pages

-

UH430L/UH650L

16 Pages

-

AQ1200L Premium

2 Pages

-

AQ900L Premium

2 Pages

-

OPM250L

24 Pages

-

Produkt Range Brochure

28 Pages

-

ALC600G

2 Pages

-

ALC400G

2 Pages

-

OPM350L

2 Pages

-

AP250L

2 Pages

-

AQ1500L

2 Pages

-

AQ1200L

2 Pages

-

AQ750L

2 Pages

-

SLC600G

2 Pages

-

SLC400G

2 Pages

-

AP3L

2 Pages

-

AQ15L

2 Pages

-

AG100L

2 Pages

-

AG80L LST

2 Pages

-

AG40L

2 Pages

-

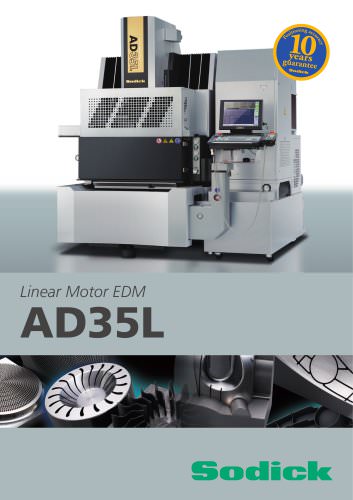

AD35L

2 Pages

-

AP1L

2 Pages

-

K1C/K3HN

4 Pages

-

VL400Q/VL600Q

4 Pages

-

Linear Product Range

24 Pages

-

AG80L LST / AG100L

4 Pages

-

AQ15L / AQ20L

4 Pages

-

AD35L / AD55L

4 Pages

-

ad55l

2 Pages

-

aq20l

2 Pages

-

AP250 L

6 Pages

-

SLC-G Series

8 Pages

-

VZ300L/VZ500L

6 Pages

-

Linear EDM Range

20 Pages

Archived catalogs

-

AP1L/AP3L

8 Pages

-

Linear Motor EDM AD35L

4 Pages

-

SLG

8 Pages

-

SLQ

2 Pages

-

AQ400L

8 Pages

-

VZ300L

2 Pages

-

AQ45L

6 Pages

-

AD30L

6 Pages

-

Product Range

6 Pages

-

Sodick - Linear Motor Wire EDM

13 Pages

-

Sodick - Linear Motor Sinker EDM

12 Pages

-

Sodick - High Speed Hard Milling

22 Pages

-

Sodick - Small Hole EDM

6 Pages