Catalog excerpts

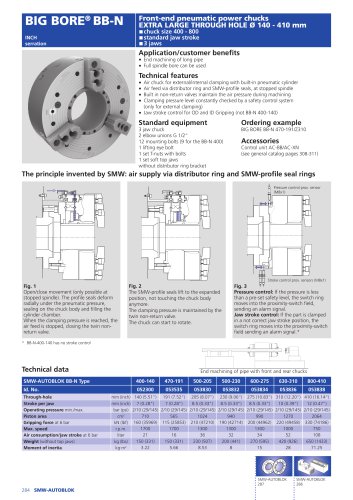

The principle invented by SMW: air supply via distributor ring and SMW-profile seal rings Application/customer benefits • Universally used in turning machines, rotary tables, handling equipment, welding etc. • For machines without hydraulic cylinder • Easy exchange for manual chucks Technical features • Power chuck with built-in pneumatic cylinder. Force transmission via wedge hook • Mounting of the distributor ring on the headstock or with the centering ring on the chuck with anti-rotation bracket • Open and close only at stopped spindle. Air transmission via distributor ring and SMW-profile seals (monitoring by SMW control cabinet) • Easy installation with no additional adapters required Standard equipment Ordering example 1 set T-nuts with bolts 1 set soft top jaws _ 2 elbow unions G1/4" (G1/8" on SP 125) Control units Spacer ring and centering ring, without (see general catalog pages 308-311) distributor ring bracket/anti-rotation bracket Two ways of mounting the distributor ring: ■ spacer ring and distributor ring bracket ■ centering ring and anti rotation bracket Open/close movement (only possible at stopped spindle). The profile seals deform radially under the pneumatic pressure, sealing on the chuck body and filling the cylinder chamber. When the clamping pressure is reached, the air feed is stopped, closing the twin nonreturn valve. The SMW-profile seals lift to the expanded position, not touching the chuck body anymore. The clamping pressure is maintained by the twin nonreturn valve. The chuck can start to rotate. Distributor ring bracket fixed (stationary) on the headstock to support the distributor ring mounted with the spacer ring. No contact between the static distribution ring and the rotating chuck. Distributor ring mounted on the outer diameter of the chuck with the centering ring (teflon part subject to wear). Need of an anti-rotation bracket fixed to the machine headstock. Technical data SMW-AUTOBLOK Type * 10mm (0.39") extended stroke (must not be used for clamping) + 5mm (0.20") clamping stroke

Open the catalog to page 1

■ EXTRA large through hole ■ 3 jaws, chuck size 125 - 350 ■ SP-ES: chuck with rapid and clamping stroke inch ■ SP-L: chuck with long jaw stroke serration_ Actual gripping force diagram The data in the diagram refer to 3-jaw-chucks, newly maintained according to their service manuals, using SMW-AUTOBLOK K05 grease, operated at 6 bar (87 psi). The speeds refer to a static bracket. The static and dynamic gripping forces have been measured using MHB hard top jaws placed in a position, not exceeding the outer diameter of the chuck. A Safety advice/danger of damage: When using taller/heavier jaws...

Open the catalog to page 2

AWB-D Soft top jaws MHB-D Hard reversible top jaws * Jaws are per piece. 3 pcs. must be ordered for 1 set.

Open the catalog to page 3

spindle adapters DIN 55027 bayonet spindle adapters type C DIN 55029 camlock spindle adapters type S Special grease for manual and power chucks Can 1000 g Id. No. 011881 Grease gun (DIN 1283) for cartridges 14 Oz. (DIN 1284). ■ Also refillable from grease can 1000 g. ■ High adhesion ■ High resistance against coolant ■ High load bearing capacity ■ Low friction coefficient ■ High gripping force ■ Avoids tribocorrosion Lubrication set Id. No. 083726 Supply range ■ Grease gun ■ 1 Adapter flexible for high pressure grease nipple ■ 1 Adapter for cone grease nipple

Open the catalog to page 4All SMW AUTOBLOK catalogs and technical brochures

-

SR-CL

2 Pages

-

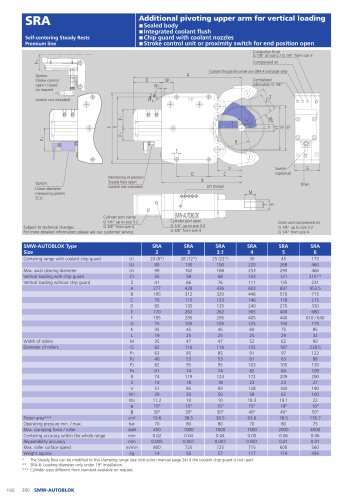

SRA

2 Pages

-

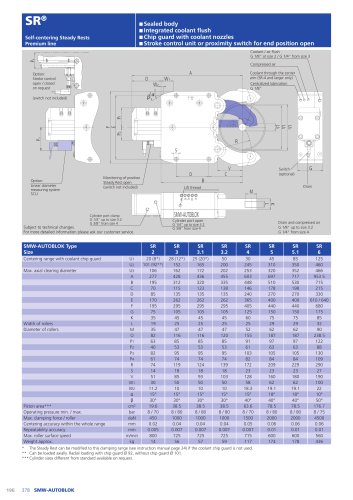

SR®

2 Pages

-

SLU

2 Pages

-

SLUB-A

2 Pages

-

SLUB

2 Pages

-

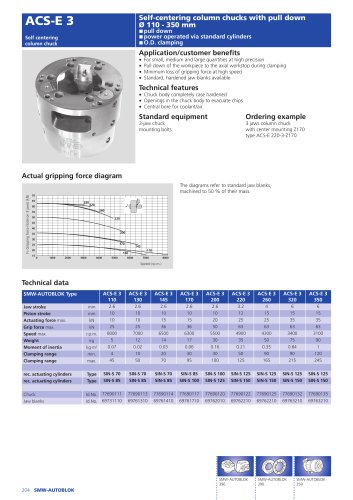

ACS-E 3

9 Pages

-

GSA

2 Pages

-

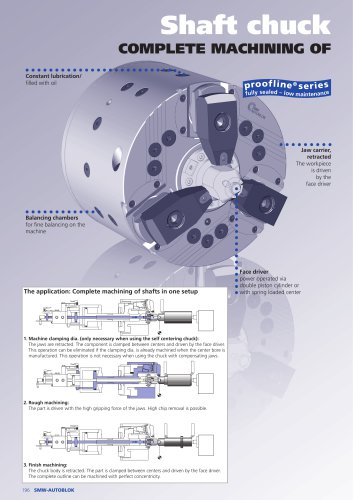

Shaft chuck

6 Pages

-

VSG

1 Pages

-

VNK-T2

3 Pages

-

SIN-S

2 Pages

-

US-CL US-A

2 Pages

-

US-Large Diameters

2 Pages

-

HB-D HB-C

2 Pages

-

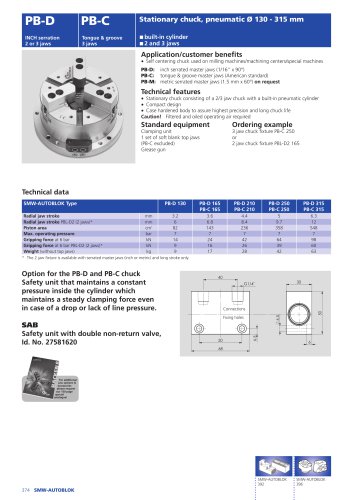

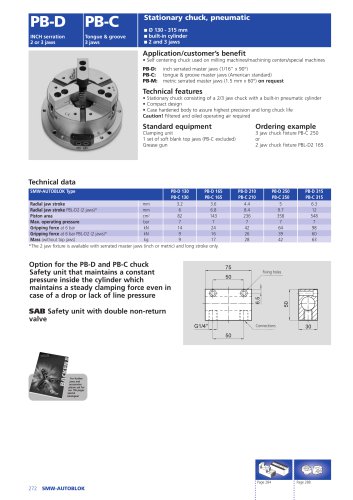

PB-D PB-C

2 Pages

-

PBM

2 Pages

-

CPG

2 Pages

-

GFT®-X

3 Pages

-

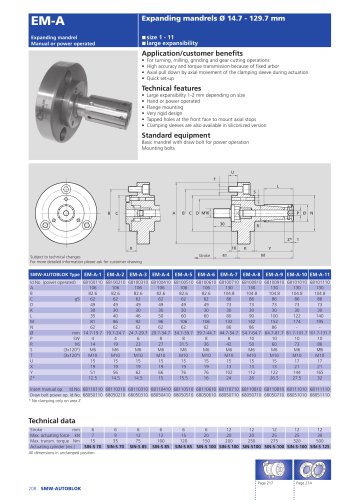

EM-A/ EM-AL

4 Pages

-

BIG BORE® BB-N

4 Pages

-

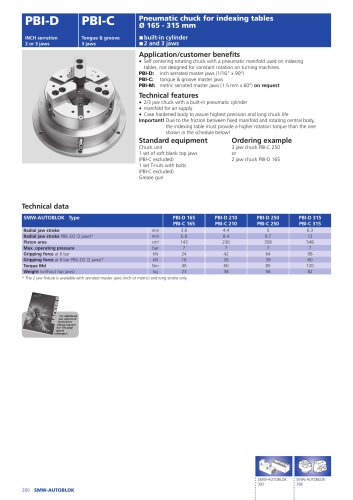

PBI-D / PBI-C

2 Pages

-

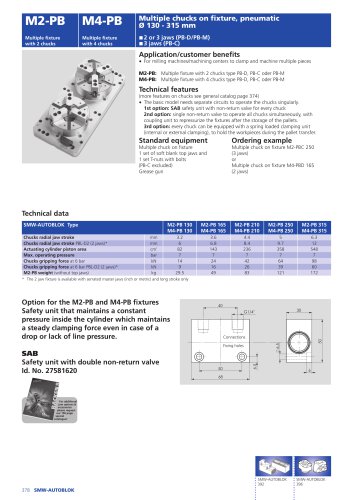

M2-PB / M4-PB

2 Pages

-

Mandrels EM-A

2 Pages

-

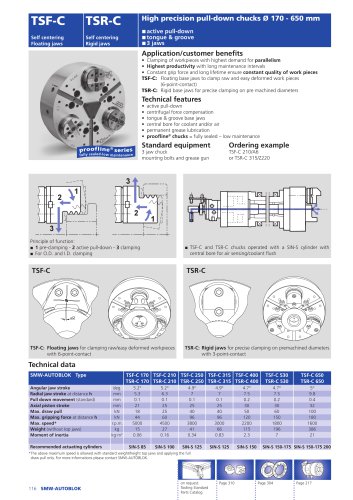

Pull Down Chucks TSF-C

2 Pages

-

Steady Rests SLU-X

3 Pages

-

Collet Chucks KSZ-MB

4 Pages

-

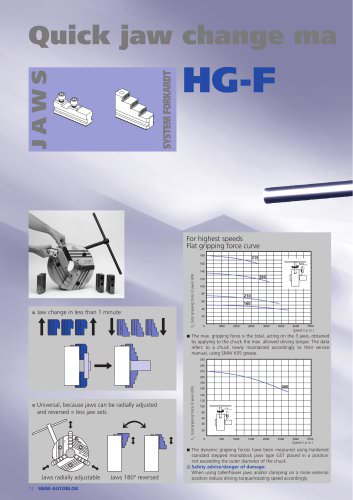

Manual Chucks HG-F

6 Pages