Catalog excerpts

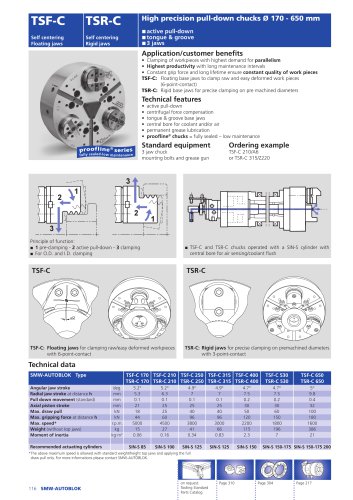

Self centering Floating jaws Self centering Rigid jaws High precision pull-down chucks Ø 170 - 650 mm ■ active pull-down ■ tongue & groove ■ 3 jaws Application/customer benefits • Clamping of workpieces with highest demand for parallelism • Highest productivity with long maintenance intervals • Constant grip force and long lifetime ensure constant quality of work pieces TSF-C: Floating base jaws to clamp raw and easy deformed work pieces (6-point-contact) TSR-C: Rigid base jaws for precise clamping on pre machined diameters Technical features • active pull-down • centrifugal force compensation • tongue & groove base jaws • central bore for coolant and/or air • permanent grease lubrication • proofline® chucks = fully sealed – low maintenance Standard equipment Ordering example 3 jaw chuck mounting bolts and grease gun Principle of function: ■ 1 pre-clamping - 2 active pull-down - 3 clamping ■ For O.D. and i.D. clamping ■ TSF-c and TSR-c chucks operated with a Sin-S cylinder with central bore for air sensing/coolant flush TSF-C: Floating jaws for clamping raw/easy deformed workpieces with 6-point-contact TSR-C: Rigid jaws for precise clamping on premachined diameters with 3-point-contact Technical data SMW-AUTOBLOK Type Angular jaw stroke Radial jaw stroke at distance h Pull down movement (standard) Axial piston stroke Max. draw pull Max. gripping force at distance h Max. speed* Weight (without top jaws) Moment of inertia Recommended actuating cylinders TSF-C 170 TSF-C 210 TSF-C 250 TSF-C 315 TSF-C 400 TSR-C 170 TSR-C 210 TSR-C 250 TSR-C 315 TSR-C 400 deg. mm mm mm kn kn r.p.m. kg kg·m2 *The above maximum speed is allowed with standard weight/height top jaws and applying the full draw pull only. For more informations please contact SMw-auTOBLOk. on request: Tooling Standard Parts catalog

Open the catalog to page 1

■ active pull-down ■ tongue & groove ■ 3 jaws Fine radial adjustment key see page 126 Self centering Floating jaws High precision pull-down chucks Ø 170 - 650 mm Self centering Rigid jaws Master jaws in middle stroke position (horizontal) iSO-a direct mounting C D E F G h8 HF/HA K Through-hole L M M1 Thread/depth N h8 P Q at middle stroke Q1 at middle stroke Rmed at middle stroke S T1 U° Radial stroke U Radial stroke (1) Pull-down s/d (option)V W axial wedge stroke Z Only TSF-c max. α b e f Reference height h j l1 l2 m1 Thread/depth m2 Thread/depth n h8 o1 h7 o2 h7 p1 p2 p3 p4 p5 p7...

Open the catalog to page 2All SMW AUTOBLOK catalogs and technical brochures

-

SR-CL

2 Pages

-

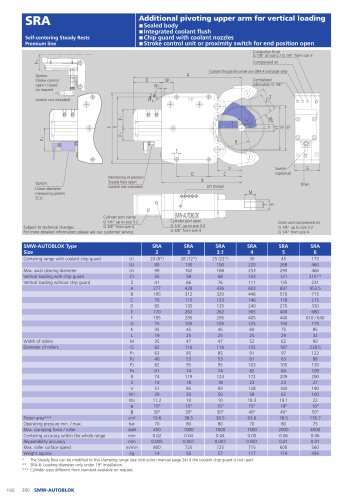

SRA

2 Pages

-

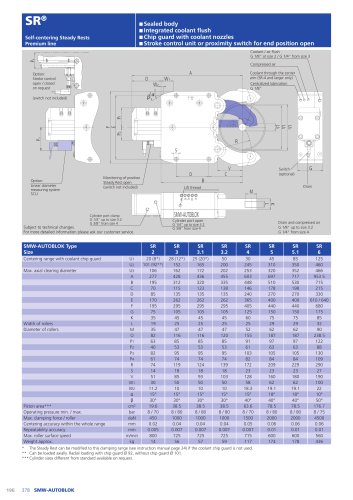

SR®

2 Pages

-

SLU

2 Pages

-

SLUB-A

2 Pages

-

SLUB

2 Pages

-

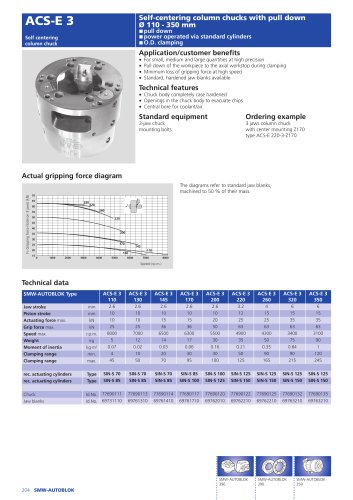

ACS-E 3

9 Pages

-

GSA

2 Pages

-

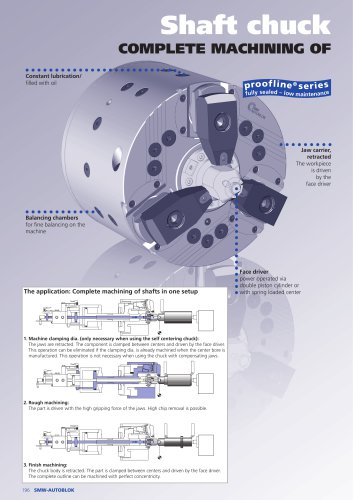

Shaft chuck

6 Pages

-

VSG

1 Pages

-

VNK-T2

3 Pages

-

SIN-S

2 Pages

-

US-CL US-A

2 Pages

-

US-Large Diameters

2 Pages

-

HB-D HB-C

2 Pages

-

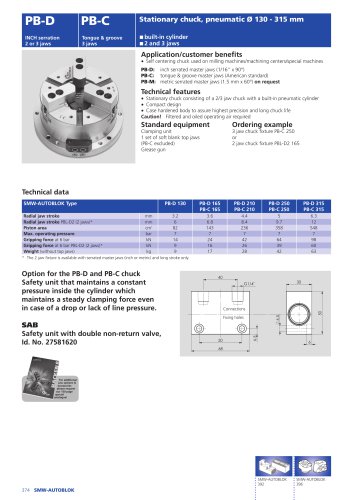

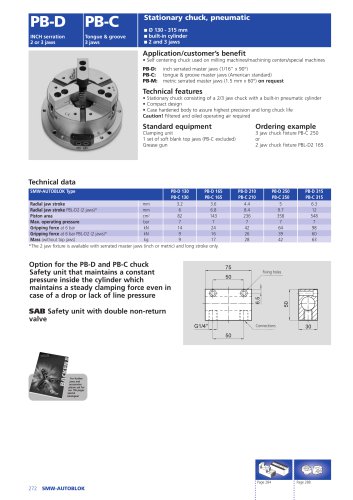

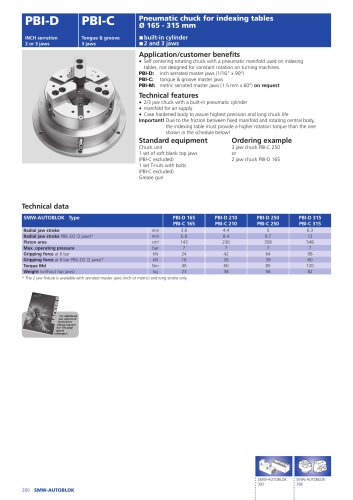

PB-D PB-C

2 Pages

-

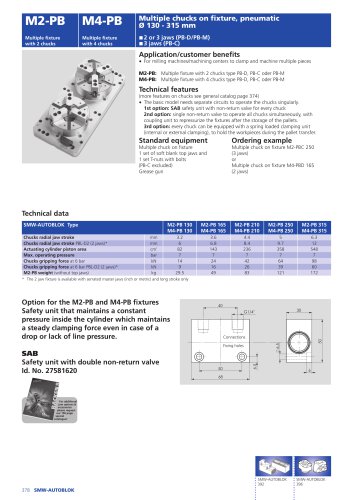

PBM

2 Pages

-

CPG

2 Pages

-

GFT®-X

3 Pages

-

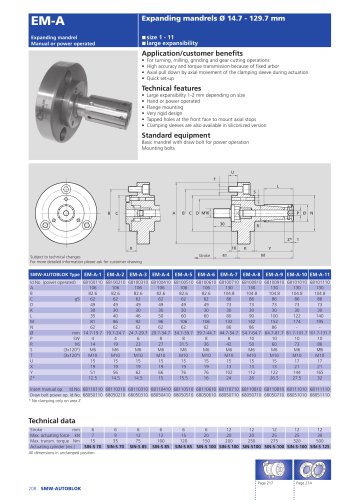

EM-A/ EM-AL

4 Pages

-

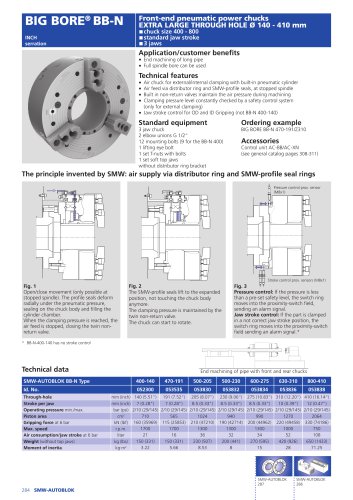

BIG BORE® BB-N

4 Pages

-

SP®+ SP-ES + SP-L

4 Pages

-

PBI-D / PBI-C

2 Pages

-

M2-PB / M4-PB

2 Pages

-

Mandrels EM-A

2 Pages

-

Steady Rests SLU-X

3 Pages

-

Collet Chucks KSZ-MB

4 Pages

-

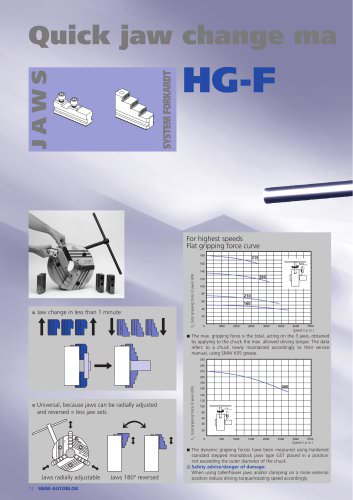

Manual Chucks HG-F

6 Pages