Catalog excerpts

QM2100 FULLY AUTOMATED TABLETOP PICK & PLACE MACHINE A remarkable and economical Pick & Place machine intended for small batches & SMT prototype projects. Features and Benefits • Teledyne DALSA Vision System • Two Heads for pick up • Static Fixture max size 14"(355mm)×12"(304mm) capable of holding one JEDEC Tray once PCB. • Operates with pneumatic feeders, 20 ports installed in the front, 20 more ports optional (for rear side) • One up looking camera for part inspection before placement. • One Down looking camera for Fiducial Recognition & feeder set up. • Placement rate 3,000 Parts Per Hour • Two day Training Session at our California office The QM2100 is a fully automated pick & place machine intended for SMT manufacturing and producing prototypes, developed by SMTmax. This remarkable, highly flexible and economical pick & place machine provides the need for a machine that produces small batches & prototypes for the

Open the catalog to page 1

QM2000 Fully Automated Tabletop Pick & Place Machine High precision with Dalsa Vision system and camera The QM2100 is standard equipped with the latest generation Dalsa Vision system, which gives you repeatability and alignment correction before placement. One down looking camera is standard for fiducial recognition and feeder alignment. One up looking camera is standard for part correction down to 0201. A second camera with larger lens for placement of large fine pitch components is optional.

Open the catalog to page 2

QM2100 Fully Automated Tabletop Pick & Place Machine Dual Head Placement Two Placement head with individual Z-axis controlled and programmable nozzle exchanger, each head can pick up component from same or different feeders.

Open the catalog to page 3

QM2100 Fully Automated Tabletop Pick & Place Machine Static PCB & JEDEC Tray Fixture Static Fixture standard with maximum adjusting size 17"(431mm)× 12"(304mm) and minimum size of 1”(25mm) x 1”(25mm) Dual arms capable of holding one JEDEC Tray once PCB depending on overall SMT board size. Maximum head travel area 20"(504mm)×20"(504mm) In line Conveyor is option

Open the catalog to page 4

Advance Air Actuated Feeder System controller (Included) The QM2100 is standard equipped with a set of 20 feeder port carriers, mounted on the front side of the machine, each port can fit one single 8mm feeder, larger size feeders may take more space away, additional set of 20 feeder ports can be added to the rear of the machine for an additional cost. Feeders are not included and sold separately. Yamaha CL32inm Yamaha CL44inm Yamaha CL561H111

Open the catalog to page 5

QM2100 Fully Automated Tabletop Pick & Place Machine Automatic nozzle Changer (optional) The QM2100 is standard equipped with Ten SMT nozzles ranging from 0.5mm up to 5.0mm and one nozzle stem. The nozzle changer fixture is designed for automatic nozzle exchanging and is highly recommended for placement of difference size SMT components. It can be program by using the down looking camera and software to automatically place back current nozzle and pick up required nozzle for larger or smaller component.

Open the catalog to page 6

QM2100 Fully Automated Tabletop Pick & Place Machine PCB Inline Transporting Conveyor (optional) The inline transporting conveyor is ideal for full turn key line that will allow you to link up to a inline stencil printer or inline reflow oven. PCB is inserted on the right side and will automatically convey to the center of the pick and place, after completion it will convey outside. Width is adjustable and can be opened up to 8” (203mm) and the maximum length of 17” (431mm

Open the catalog to page 7

For small strips of SMD tape we offer a five For SMD components package in plastic tube, channel tape strip feeder that can be adjusted vibratory feeder can hold up to five tubes to any width of tape. depending on tube width, each channel

Open the catalog to page 8

QM2100 Fully Automated Tabletop Pick & Place Machine Dispensing Adaptor (Optional) Dispensing head option for applying solder paste or SMD-glue, controlled by the SMTmax software! The PCB’s Gerber file can be converted into a dispensing list file providing all dispense positions, can also be programmed one at time by teach mode, recommended for prototyping. Dispensing can be done directly from the 10cc syringe by time pressure.

Open the catalog to page 9

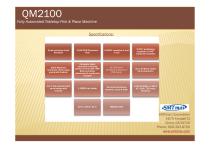

QM2100 Fully Automated Tabletop Pick & Place Machine Specifications: 2 pick and place head Standard 0.001" positioning resolution, 0.045° rotational resolution 0201 Minimum Component Size (using pneumatic feeders) Computer vision automatic centering system for IC's (SOP, QFP, BGA) and better placement of small parts included Up to 40 8mm feeder ports maximum. X & Y Axis standard with servo motors with encoder 1 JEDEC tray holder 12 month full factory warranty - parts & labor SMTmax Corporation 5675 Kimball Ct Chino, CA 91710 Phone: 909-393-8700 www.smtmax.com

Open the catalog to page 10All SMT MAX catalogs and technical brochures

-

QM1100

9 Pages

-

SZM SERIES

15 Pages

-

chipcounter

47 Pages

-

QM1100-A

9 Pages

-

QM1500ds

10 Pages

-

QM3000

10 Pages

Archived catalogs

-

QK855PG BGA Repair System

9 Pages

-

QK702ESD 3-in-1 Rework Station

16 Pages

-

Screen Printer QSY3401

3 Pages

-

AE Reflow Oven

21 Pages

-

Automatic Paste Dispenser

15 Pages