Catalog excerpts

57, avenue Pierre Brossolette - 69500 Bron (France)Adresse postale : SMP 69675 BRON Cedex France T֩l. : +33 (0)4 72 15 51 70 - fax : +33 (0)4 72 15 51 71 www.smp.fr - smp@smp.fr centres d'afftage - plateaux diviseurs CN - sous-traitance de technologie et ingnierie tools cutter grinders - NC rotary tables - hightech subcontracting & engineering >

Open the catalog to page 1

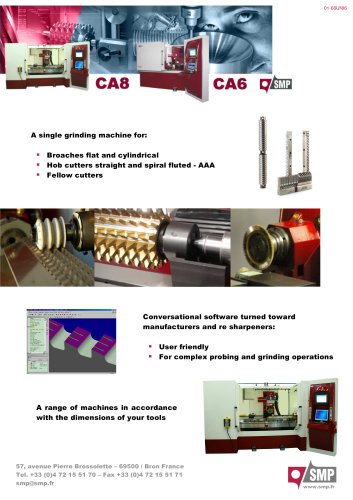

- 3 linear axes, (X,Y,Z) : - driven in motion by endless screws with centralized lubrification of all ball guide ways, - 2 rotary axes (A and B) : - the A axis, which supports the work piece, is driven in rotation by a brushless motor enabling cylindrical grinding operations. - the B axis, which supports the electro-spindle, is driven in rotation by a worm and worm wheel of high accuracy. > Placing the active face of the grinding wheel close to the electro spindle centre of rotation, the indexing error of this axis is neutralized. The compensation strokes on linear axes, whilst the rotary...

Open the catalog to page 3

mmVertical X: 350 0.001 16 m/mn mmTransversal Y: 200 0.001 16 m/mn mmHorizontal Z: 300 0.001 16 m/mn Axe A 0.001 800 rpm Axe B -120а/+1200.001а 9 rpm > A axis SA 50 (1) > / Electro spindle taper HSK E40 (2) > / Max. tool diameter mm150 (3) > 20 (6) 16 Max. tool length mm300(4) > 150 (7) 140 Max. grinding wheel diameter mm125 (5) > 125 125 Max. weight kg 25 > 3 / (1) Other on request (already done HSK A63, HSK A80, SA 40) (2) Other on request (already done SA 30) (3) Up to 300 mm if no peripheral grinding operation (4) 950 mm if re sharpening of gun drills (5) 200 mm without wheel changer...

Open the catalog to page 4

Electro spindle driven by brush less motor to enhance surface finishes. Torque available at low speed for deep grinding operations (15 Nm up to 6000 rpm). This working point is extremely important all the more that working speed in carbide has collapsed from 20 m/s to 12 m/s this last 3 years. Max speed up to 20 000 rpm for working with small grinding wheels Ceramic bearings Separated coolant device HSK wheel hub attachment > A RENISHAW probe, fitted onto the machine head, measures parameters like diameters, lengths, helix anglesօ This device also enables a correction of the run out to give...

Open the catalog to page 5

Universal solution : large working area to add a return station of tool, possibility to modify the jaws easily, the pallets or to adapt your standard Reliability: The nuclear industry has retained the SCARA type on this criteria. An easy set up : a training period of 80 min Loading in tool holder which ensured 0.003 mm of run out > 57, avenue Pierre Brossolette - 69500 Bron (France)Adresse postale : SMP 69675 BRON Cedex France T֩l. : +33 (0)4 72 15 51 70 - fax : +33 (0)4 72 15 51 71 www.smp.fr - smp@smp.fr centres d'afftage - plateaux diviseurs CN - sous-traitance de technologie et...

Open the catalog to page 6

57, avenue Pierre Brossolette - 69500 Bron (France)Adresse postale : SMP 69675 BRON Cedex France T֩l. : +33 (0)4 72 15 51 70 - fax : +33 (0)4 72 15 51 71 www.smp.fr - smp@smp.fr centres d'afftage - plateaux diviseurs CN - sous-traitance de technologie et ingnierie tools cutter grinders - NC rotary tables - hightech subcontracting & engineering >

Open the catalog to page 7

Loading of the tool with its tool holder HSK A63 > Working with plain oil or with soluble oil (plain oil recommended) Out let pressure pump 10 bar, flow rate 100 l / min Paper filtering unit, Transor > 57, avenue Pierre Brossolette - 69500 Bron (France)Adresse postale : SMP Ŗ 69675 BRON Cedex France Tl. : +33 (0)4 72 15 51 70 - fax : +33 (0)4 72 15 51 71 www.smp.fr - smp@smp.fr centres d'afftage - plateaux diviseurs CN - sous-traitance de technologie et ing黩nierie tools cutter grinders - NC rotary tables - hightech subcontracting & engineering size="-2">

Open the catalog to page 8

Watering is a key point of grinding operations to achieve high quality results. For this we use calibrated and rigid nozzles : To control watering speed at the working point of the grinding wheel (faster than the tangential speed of the grinding wheel to pierce the film of air around the grinding wheel) To keep the pressure To avoid any risk of collisions with the axes motions > For deep machining operations, in addition to 8 nozzles, we propose a retractable nozzle fitted into a piston which approaches the nozzle very closely to the working point of the wheel. At the end of the working...

Open the catalog to page 9

Ref doc 3 GB Rev 070302 Page 10/18 The main avantages are keeping your measurement devices free from oil, reducing drying time, automation of cleaning operation, stopping oil spraying outside the machine, making the use of a degreasing product tank unnecessary, Saving oil and rags. > Electro-static vacuum cleaner 1200 Nm3/h None consumable requiredOther device on demand > Enclosure with built in safety relief valve connected to the machine power cut-off. (Spray of CO2 as option > 57, avenue Pierre Brossolette - 69500 Bron (France)Adresse postale : SMP 69675 BRON Cedex France T֩l. : +33 (0)4...

Open the catalog to page 10

The operator programs the re sharpening or the manufacturing of a tool through a PC and the conversational software Numaffut+ without any knowledge of ISO code. These parameters are compiled into an ISO program directly by the software Numaffut+. The program can be transferred toward: - the CNC to carry out machining operations, - the 3D simulation software : NC Simul. > 5 axes CNC NUM AXIUM POWER Display 15Ғ PC according last evolutions Windows Xp Display 17Ғ > The Numaffut+ software, developed by SMP since 1985, is probably the most complete of the market. it gathers on base: end mills,...

Open the catalog to page 11

57, avenue Pierre Brossolette - 69500 Bron (France)Adresse postale : SMP Ŗ 69675 BRON Cedex France Tl. : +33 (0)4 72 15 51 70 - fax : +33 (0)4 72 15 51 71 www.smp.fr - smp@smp.fr centres d'afftage - plateaux diviseurs CN - sous-traitance de technologie et ing黩nierie tools cutter grinders - NC rotary tables - hightech subcontracting & engineering >

Open the catalog to page 12

57, avenue Pierre Brossolette - 69500 Bron (France)Adresse postale : SMP 69675 BRON Cedex France T֩l. : +33 (0)4 72 15 51 70 - fax : +33 (0)4 72 15 51 71 www.smp.fr - smp@smp.fr centres d'afftage - plateaux diviseurs CN - sous-traitance de technologie et ingnierie tools cutter grinders - NC rotary tables - hightech subcontracting & engineering >

Open the catalog to page 13All SMP TECHNIK catalogs and technical brochures

-

VG 300

1 Pages

-

Toolshools

2 Pages

-

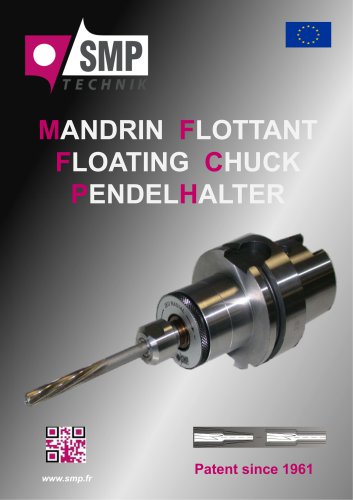

FLOATING CHUCKS CATALOGUE

110 Pages

Archived catalogs

-

Plateaux SuperPremium

21 Pages

-

Plateaux Premium

17 Pages

-

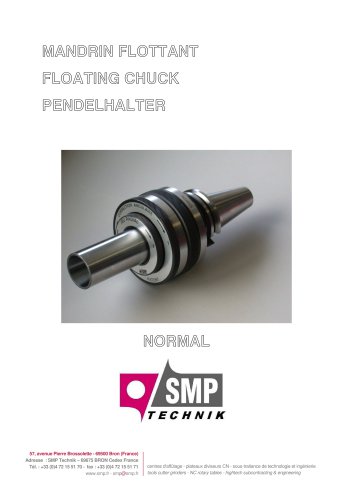

FLOATING CHUCK - NORMAL

23 Pages

-

FLOATING CHUCK - COMPACT GV

52 Pages