Catalog excerpts

EXTRUSION LINES - ENGINEERED TO PERFORM ► SPINNING LINES

Open the catalog to page 1

SPINNING LINES

Open the catalog to page 2

SPINNING LINES AUSTROFIL BCF MONOCOLOUR “TWIN“ INTRODUCTION Yarns manufactured using SML technology represent a quality benchmark in the carpet industry and the BCF (Bulked Continuous Filament) process is the most efficient method for their production. Manufacturing yarns for carpet design with the highest possible efficiency and flexibility requires well planned production lines. SML’s innovative detail engineering, the steady improvement and development of core components results in spinning plants that enable the company’s customers to position themselves successfully in the highly...

Open the catalog to page 3

SPINNING LINES SPINNING LINES FOR BCF PP YARNS

Open the catalog to page 5

SPINNING LINES AUSTROFIL BCF PP MONOCOLOUR “COMPACT” SML’s BCF “Compact” spinning line is custom-designed for the production of small yarn lots with maximum efficiency and flexibility. With an output of 160kg/h this line is equipped with only one extruder and two stretching sections. Two spinnerets per yarn provide perfect cooling conditions, which result in high output and excellent yarn quality. Top prod- u MAXIMUM EFFICIENCY AND FLEXIBILITY u HIGH OUTPUT AND EXCELLENT YARN QUALITY u WIDE TITER RANGE PRODUCTION WITHOUT ANY TEXTURING SYSTEM COMPONENT CHANGES uct standards also derive...

Open the catalog to page 6

SPINNING LINES PERFORMANCE LEVEL BCF PP 2x2C / 75 Compact, 4 ends, monocolour Automatic turret winder Titer range Mechanical winding speed Output capacity Bobbin diameter SPACE REQUIREMENT LINE CONFIGURATION Extruder lnverter controlled AC motor 1 unit 75 / 28D Incl. static mixer Feeding section Water cooled, closed circuit Spinning beam Electrically heated Spinning pumps Heberlein, Migra-Jet Ø 160mm, inductive heated, bearing lifetime lubricated Texturing system AUSTROJET patented without lamellas Cooling process Heberlein, PolyJet-TopAir CONNECTED LOAD AND AIR CONSUMPTION Connected load...

Open the catalog to page 7

SPINNING LINES BCF PP MONOCOLOUR “TWIN” Apart from offering yarn production at maximum productivity, the BCF Monocolour “TWIN” is ideally suited for simultaneous BCF PP MONOCOLOUR production of either 8 absolutely identical yarns or two times 4 yarns with different specifications such as titer and the number of filaments. The line therefore has two extruders and two independent spinning sections. u TWICE THE OUTPUT u SIMULTANEOUS PRODUCTION OF TWO YARNS WITH DIFFERENT SPECIFICATIONS u EVERY LINE ADJUSTMENT POSSIBLE USING INDIVIDUAL PARAMETERS In addition, it is also possible to run with...

Open the catalog to page 8

SPINNING LINES PERFORMANCE LEVEL BCF PP 4x2 / 2x75 TWIN, 8 ends, monocolour Automatic turret winder Titer range Mechanical winding speed Output capacity Bobbin diameter SPACE REQUIREMENT LINE CONFIGURATION Extruder lnverter controlled AC motor 2 units 75 / 28D Incl. static mixer Feeding section Water cooled, closed circuit Spinning beam Electrically heated Spinning pumps Heberlein, Migra-Jet Ø 160mm, inductive heated, bearing lifetime lubricated Texturing system AUSTROJET patented without lamellas Cooling process Heberlein, PolyJet-TopAir CONNECTED LOAD AND AIR CONSUMPTION Connected load...

Open the catalog to page 9

SPINNING LINES BCF PP TRICOLOUR The BCF Tricolour spinning line offers maximum carpet design efficiency and flexibility, and multiple colour combinations for BCF yarn production. configuration is used to produce unique yarns according to individual requirements and to meet new fashion trends. Yarns produced on SML lines represent a carpet industry benchmark, as outstanding levels of cooling efficiency after texturing result in high output and excellent yarn quality. Two pre-intermingling positions allow a wide range of colour separations (from melange to sprinkle). In the carpet industry...

Open the catalog to page 10

SPINNING LINES PERFORMANCE LEVEL BCF PP 4x2 T / 3x75, 8 ends, tricolour Automatic turret winder Titer range Mechanical winding speed Output capacity Bobbin diameter SPACE REQUIREMENT LINE CONFIGURATION Extruder lnverter controlled AC motor 3 units 75 / 28D Incl. static mixer Feeding section Water cooled, closed circuit Spinning beam Electrically heated with thermic oil Spinning pumps Heberlein, Migra-Jet, 2 positions Ø 160mm, inductive heated, bearing lifetime lubricated Texturing system AUSTROJET patented without lamellas Cooling process Heberlein, PolyJet-TopAir CONNECTED LOAD AND AIR...

Open the catalog to page 11

SPINNING LINES

Open the catalog to page 12

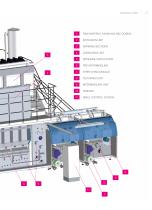

SPINNING LINES SPINNING SECTIONS QUENCHING UNIT SPINFINISH APPLICATION STRETCHING MODULE TEXTURING UNIT INTERMINGLING UNIT EXTRUSION UNIT RAW MATERIAL HANDLING AND DOSING SMILE CONTROL SYSTEM

Open the catalog to page 13

SPINNING LINES Extrusion unit RAW MATERIAL HANDLING AND DOSING Very accurate gravimetric loss-in-weight systems are integrated into SML’s BCF lines for exact and reproducible colour effects. In addition, apart from the main component, as a rule two ancillary components for additives such as colour masterbatch or UV stabilisers are installed. The main functions are actuated using the SMILE control panel for easy operation at ground level. EXTRUSION UNIT SML BCF spinning lines are equipped with highly efficient, single screw extruders with a 75mm screw diameter and an L/D ratio of 28. High...

Open the catalog to page 14

SPINNING LINES Spinning section SPINNING SECTIONS BCF MONO / TWIN A spinning beam with electrical plate heaters is used for stable operation and easy maintenance. All the spinning pumps have two outlets and supply the melt stream to eight spinpacks with 110mm in diameter. Equal residence time for every melt stream is secured and this results in uniform yarn quality. Moreover, an absolutely vertical yarn path ensures excellent spinning quality and problem-free production. BCF TRICOLOUR In this case, the large spinning beam is heated by thermal oil in order to obtain a constant temperature...

Open the catalog to page 15

SPINNING LINES Spinfinish application SPINFINISH APPLICATION Spinfinish oil is supplied very accurately to the ceramic applicator nozzles by means of precision metering gear pumps. A single pump outlet for each yarn ensures that an exact and equal amount of oil is applied. The spinfinish tank is equipped with a level sensor and a filter prevents supply system blockages. BCF MONO / TWIN The single yarns are compacted in the preintermingling station by means of air jets. This provides enhanced processing performance throughout the entire line. BCF TRICOLOUR Two pre-intermingling systems are...

Open the catalog to page 16All SML Maschinengesellschaft catalogs and technical brochures

-

HYGIENE FILM

14 Pages

-

STRETCH WRAP

18 Pages

-

PP / PE / PET BARRIER FILM

17 Pages

-

COATING LINES

2 Pages

-

PET / R-PET SHEET

28 Pages

-

CAST FILM LINES

32 Pages

-

austrofil HT/MT version

2 Pages

-

SERIES W4000 CAST

2 Pages

-

SERIES ECOFLEX / POWERFLEX

2 Pages

-

CPP EXTRUSION

2 Pages

-

high performance extruder

2 Pages

-

smile control system

2 Pages

-

winder series W3000 cast

2 Pages

-

winder 2000

2 Pages

-

SML

15 Pages

-

Spinning lines

16 Pages

-

Coating lines

12 Pages

-

Sheet lines

9 Pages

-

Cast film lines

20 Pages