Catalog excerpts

On the markel for more than 40 years, the company SME was established in 1967 by Mario Caroli in Ozzano dell'Emilia (Bologna. Italy). Its craftmade production was mainly consisting of of washing systems for Olivetti typewriters. Soon after the first parts washers were built for mechanical parts cleaning in the maintenance sector of cars, trucks and tractors. In the late 70's Aurelio Caroli becomes the new manager, giving a dynamic impulse to the company. SME s.r.l. was established in 1987 and. inheriting all the experience gained over the years, it continues its positive growth trend. Till...

Open the catalog to page 2

SME systems have always been considered synonymous of quality and reliability. Over the years SME has studied how the various types of washing jet influence the quality of the washing process. The best choice adopted by SME is certainly to use the "pin" jet: it is called in this way because the water jet comes out of the nozzle shaped as a pin, differently from the blade or "fan" jet. The most obvious defects of the washing system with blade nozzles are: £> water pressure on the part to be washed is much lower than the maximum pump pressure <& greater is the distance of the blade nozzle...

Open the catalog to page 3

The electrical panel - DGT V3 - by Crouzet (s Models: Simplex. Atom. Simplex Big. The PLC installed on DGT V3 systems is a Crouzet commercial PLC, which manages signal inputs and outputs and controls the activation of resistors and motors. The panel is made up of electromechanical components, supplied with three phase current and the control circuit works at 24VDC. The software installed on the PLC allows you to; 0 customize machine functions (time, temperatures, etc.) 0 set the weekly programming for the activation of the washing liquid heating <2> set the weekly programming for the...

Open the catalog to page 4

Minilav is a compart and srtrong system lor successfully washing of small parts and it has been designed to be placed in narrow Washing is earned out by using the upper and lower jets, whose rotation is ensured by the powerful stainless steel pump. The operator can set the tank fluid temperature and the treatment • MINILAV. washing capacity of 35 x 35 x H30 cm x 20kg • electric, maximum washing temperature: 60X Supply voltage STANDARD EQUIPMENT . Basket of reinforced PVC with border H15 cm • Minimum tank level check to protect pump and resistor • Compact size, it is designed to be placed on...

Open the catalog to page 5

This system allows you to wash small and medium sized mechanical parts successfully. The treatment is performed manually by means of two gloves fitted on the front part. The cleaning results are ensured by a high pressure pump and the special spray nozzle. The latter can be quickly replaced with the cleaning brush thanks to the quick attachments. The machine is equipped with a compressed air gun for drying the parts and extracting the vapours produced inside the chamber. • electric, maximum washing temperature: 60°C (C) Supply voltage • compressed air (pneumatic version) STANDARD EQUIPMENT...

Open the catalog to page 6

LAVAPEN: Manual washing

Open the catalog to page 7

P: Automate washing with motorized basket P is a system that washes mechanical parts automatically. Washing is carried out by the upper, lower and side jets, the basket turn thanks to a gearmotor. Control panel is composed by electromechanic components. The operator can set the tank fluid temperature and the treatment time. • electrical LT, maximum washing temperature: 60°C Supply voltage STANDARD EQUIPMENT • Electromechanical control panel • Mechanical basket rotation with gearmotor • Electrical vapour extraction (P100/P120) • Reinforced basket of electrowelded net with external edge of...

Open the catalog to page 8

P: Automate washing with motorized basket

Open the catalog to page 9

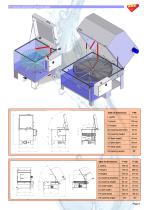

SIMPLEX: Automate washing with motorized basket Simplex is a system that washes small and medium sized mechanical parts automatically. Washing is carried out by means of the upper, lower and side jets, the basket slow rotation is ensured by a gearmotor. The PLC allows you to manage time, temperatures, levels, signals and alarms. The easy to use and Intuitive software is available in many • Simplex 60, washing capacity of 058 x H38 cm x 100kg • Simplex 80. washing capacity of 078 x H43 cm x 100kg • electric LT. maximum washing temperature: 60°C • electric HT, maximum washing temperature:...

Open the catalog to page 10

SIMPLEX: Automate washing with motorized basket AVAILABLE ACCESSORIES © High pressure pump © Basket of Stainless steel Aisi 304 Vapour extraction (included for HT model) © Integrated disc oil separator Panels under the basket with grease collecting filters (included for model HT) ® Blowing with compressed air and independent pipes 'O ® Preparation for the use of abrasive contaminants ® Preparation for the use of strongly caustic chemical products © Bleaching of internal welding $| Teflon and Vrton gaskets '© Models with other supply voltages "O suction and panels under the basket are...

Open the catalog to page 11

SIMPLEX: Automatic washing with motorised basket Simplex is a system that washes automatically small and medium sized mechanical parts. Washing is carried out by means of the upper, lower and side jets, the basket slow rotation is ensured via a gearmotor. The easy to use and intuitive software can display informations in many • Simplex 100, washing capacity of 097 x H54 cm x 200kg • Simplex 120, washing capacity of 0117 x H70 cm x 300kg • electric LT, maximum washing temperature: 60°C • electric HT, maximum washing temperature: 80°C Supply voltage STANDARD EQUIPMENT • Timed vapour...

Open the catalog to page 12

SIMPLEX: Automatic washing with motorised basket AVAILABLE ACCESSORIES © Manual washing and blowing with hoses and internal washing nozzle ® External trolley of stainless steel Aisi 304 "O ® System retention tank of stainless steel Aisi 304 ® Pneumatic opening and closing of the cover with two-hand safety control ® Panels under the basket with grease and chips collecting fillers (included In HT) ® Blowing with compressed air and independent pipes *i High pressure pump ® Disc oil separator with dedicated gearmotor Bag filter placed on the pump delivery *© Drying with resistor and blower with...

Open the catalog to page 13All SME catalogs and technical brochures

Archived catalogs

-

Simplex catalogue

8 Pages