Website:

SMC PNEUMATIC

Website:

SMC PNEUMATIC

Group: SMC

Catalog excerpts

Magnetically Coupled Rodless Cylinder New ø6, ø10, ø15, ø20, ø25, ø32, ø40 Weight 15 % reduced RoHS Overall length 15 mm shortened Max. Max. 0.96 kg (Existing model 1.13 kg) 240 mm (Existing model 255 mm) (CY1S 15-100 stroke) (CY1S 40-100 stroke) Reduced in length Improved durability Lub-retainers are mounted on the internal and external surfaces of the cylinder tube to maintain the lubrication. External surface lub-retainers Cylinder tube Adjustment bolt improves stroke accuracy/repeatability. Stroke position can be maintained with the adjustment bolt positioned next to the shock absorber, so stroke adjustment is not necessary. Adjustment bolt Internal surface lub-retainers Series CY1S Shock absorber CAT.ES20-227A

Open the catalog to page 1

Series CY1S Reduced in weight Weight is reduced with the redesign of the slide block and reducing the thickness of the plate. Bore size (mm) (kg) Reduction rate Existing model New CY1S 6 0.34 8% 0.37 10 0.59 13% 0.68 15 0.96 15% 1.13 20 1.68 13% 1.93 25 2.02 10% 2.25 32 3.45 12% 3.94 40 5.36 14% 6.23 Slide block At 100 stroke Plate Reduced in length Overall length is reduced, but interchangeable with the existing model. (mm) Bore size (mm) New CY1S Existing Bilateral piping type Centralized piping type model Overall length Length reduction Overall length Length reduction Overall length 6...

Open the catalog to page 2

3-Options available for stroke adjustment Bumper bolt (resin tipped) Bumper bolt (Same on the opposite side) Shock absorber + Adjustment bolt (metal ended) Adjustment bolt (Same on the opposite side) Shock absorber (Same on the opposite side) Reduced in length Shock absorber + Adjustment bolt (metal ended) on one side Bumper bolt (resin tipped) on one side Adjustment bolt Shock absorber Bumper bolt New Improved auto switch mounting zAuto switch can be mounted in any desired position. (D-M9 , D-A9 ) • The auto switch can be fixed in any desired position with a switch spacer. • This reduces...

Open the catalog to page 3

Series CY1S Model Selection Selection Flow Chart Operating Conditions D: Bore size (mm) L: Stroke (mm) m: Load mass (kg) Va: Piston speed (mm/s) P: Operating pressure (MPa) E: Kinetic energy (J) Review the operating conditions. Review the operating conditions. Mounting orientation (Horizontal, Vertical) NG ) mh: Allowable load mass by thrust in horizontal operation mv: Allowable load mass by thrust in vertical operation mh, mv: See Table 1. Check allowable load mass by thrust. m mh, mv OK Reference 1 Check allowable load mass by thrust. Reference 2 NG Check allowable load mass by stroke....

Open the catalog to page 4

Model Selection Series CY1S 1 Check allowable load mass by thrust. In this series, the work load and the maximum operating pressure are restricted to prevent the magnetic coupling from being separated. Ensure that the work load mass and operating pressure are within the values in Table 1. Table 1. Allowable load mass by thrust and maximum operating pressure Bore size (mm) Horizontal operation Horizontal operation Max. operating pressure mh [kg] Ph [MPa] Note) Vertical operation Max. operating pressure Pv [MPa] Vertical operation mv [kg] 6 1.8 1.0 10 3.0 2.7 15 7.0 20 12 25 20 18.5 32 30 30...

Open the catalog to page 5

2 Check allowable load mass by stroke. Selection Graph Graph 1] Allowable load mass by stroke Graph 3] Allowable load mass by stroke Graph 5] Allowable load mass by stroke Graph 7] Allowable load mass by stroke Graph 2] Allowable load mass by stroke Graph 4] Allowable load mass by stroke Graph 6] Allowable load mass by stroke : If load center of gravity exceeds the value of y, z + A on the graph, please consult SMC.

Open the catalog to page 6

Model Selection Series CY1S 3 Consider load factor on guides. 3 — q Types of moment applied to rodless cylinders Multiple moments may be generated depending on the mounting orientation, load, and position of the center of gravity. Coordinates and Moments M3: Yaw moment The direction of the axis, X, Y and Z are based on the cylinder mounting orientation shown on the right. Consider the direction of the axis for each mounting direction. Z M1: Pitch moment Y X M2: Roll moment Static moment calculation by mounting style [Horizontal mounting] [Ceiling mounting] M1 M2 y X Y x mxg M1 M2 X [Wall...

Open the catalog to page 7

3 Consider load factor on guides. Q—(2) Allowable load mass on guides/Allowable moment Table 4. Allowable load mass on guides and moment The table above indicates the maximum performance of the guide, but does not show the actual allowable work load mass. Refer to Graphs (8) to (13) for correct allowable mass by piston speed. Graph 8] Allowable load mass on guides (06 to o15) m Graph 10] Allowable moment (06 to o15) Graph 12] Allowable moment (06 to 015) Graph 9] Allowable load mass on guides (020 to 040) m Graph 11] Allowable moment (020 to 040) Graph 13] Allowable moment (020 to 040)

Open the catalog to page 8

Model Selection Series CY1S 3 — e Consideration of guide load factor Work load mass and allowable moment varies depending on the load mounting method, stroke, cylinder mounting orientation and piston speed. Whether the cylinder is suitable or not is decided by the allowable load mass on guides in the graphs. The selection calculation is shown below. It is necessary to consider i) allowable load mass on guides, ii) static moment and iii) dynamic moment (when the slide block collides with the stopper). i) · ii) is calculated with Va (average speed) and iii) is calculated with V (collision...

Open the catalog to page 9

Series CY1S Calculation of Guide Load Factor The selection calculation finds the load factors ( n) of the items below, where the total does not exceed 1. Load factor n Item Note 1: Maximum load mass 1 = m/mmax Examine m. mmax is the max. load mass for Va. 2: Static moment 2 = M/Mmax Examine M1, M2, M3. Mmax is the allowable moment for Va. 3: Dynamic moment 3 = ME/MEmax Examine M1E, M3E. MEmax is the allowable moment for V. Calculation example z Mounting on horizontal wall [1] Operating Conditions CY1SG25-600 Wa: Connection plate t = 10 (1.5 kg) Cylinder: CY1SG25-600 Cushion: Shock absorber...

Open the catalog to page 10All SMC PNEUMATIC catalogs and technical brochures

-

SYJ300/500/700 Series

62 Pages

-

Vacuum Unit ZK2 Series

60 Pages

-

Air Cylinder CJ2 Series

117 Pages

-

AS-FS Series

36 Pages

-

IDF series

12 Pages

-

MHL2 Series

24 Pages

-

JCM Serie

18 Pages

-

EX245 Series

12 Pages

-

Pin Cylinder CJP2/CDJP2/CJP

19 Pages

-

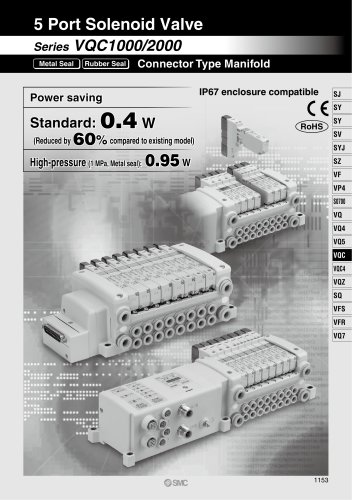

5 Port Solenoid Valve VQC

63 Pages

-

5 Port Solenoid Valve VQ

79 Pages

-

SY

268 Pages

-

5-p0979-0980-hep500

2 Pages

-

5-p0977-0978-aep100

2 Pages

-

5-p0966-0971-lmu

5 Pages

-

5-p0960-0966-alb900

6 Pages

-

5-p0956-0960-ald600

5 Pages

-

5-p0948-0950-al800

3 Pages

-

es70-44c-vx2

52 Pages

-

es50-37-kq2

124 Pages

-

ex-pcw

23 Pages

-

1-p2124-2152-ex510

29 Pages

-

1-p2111-2122-ex500

12 Pages

-

1-p2063-2073-ex260

11 Pages

-

4-p0147-0178-msu-mds

32 Pages

-

es20-230b-crb2

59 Pages

-

1-p1869-1878-vp3145

10 Pages

-

VP300/500/700 series

42 Pages

-

1-p1789-1829-vqz100

41 Pages

-

1-p1727-1788-syj300

62 Pages

-

5 Port Solenoid Valve S0700

111 Pages

-

5 Port Solenoid Valve VF

59 Pages

-

5 Port Solenoid Valve SV

127 Pages

-

VH

9 Pages

-

CUJ

41 Pages

-

AL

3 Pages

-

kj mm

9 Pages

-

AQ

4 Pages

-

SY3000/5000-X13

2 Pages

-

Series MB

24 Pages

-

Series LES

23 Pages

-

Series LEFB

16 Pages

-

Series PF3W

28 Pages

-

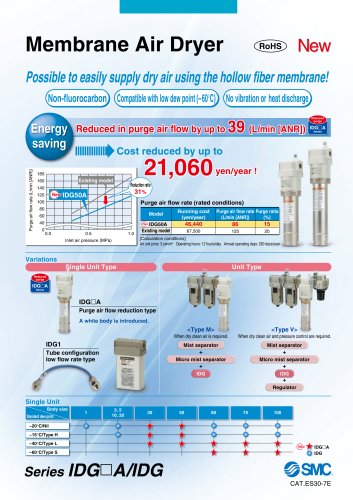

Series IDG?A/IDG

56 Pages

-

Floating Joint

7 Pages

-

Series IZS40/41/42

32 Pages

-

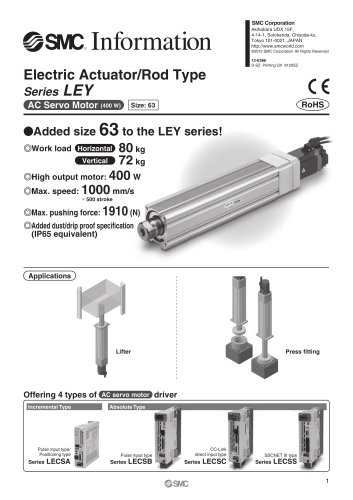

Series LEY

7 Pages

-

Series VHS

12 Pages

-

SeriesCQ2/CQS/CQ

4 Pages

-

In-line Air Filter

12 Pages

-

5 Port Solenoid Valve

60 Pages

-

Series CQ2/CQS

2 Pages

-

AS series

2 Pages

-

corporate guide

13 Pages

-

ZP

69 Pages

-

ZFA

14 Pages

-

ZA

13 Pages

-

MHF

32 Pages

-

MHZ

68 Pages

-

CRB

44 Pages

-

D

117 Pages

-

RB

23 Pages

-

CEP

44 Pages

-

RSK

30 Pages

-

CLK

51 Pages

-

MK

20 Pages

-

GLJ

65 Pages

-

MGJ

7 Pages

-

Mx

36 Pages

-

MXH

18 Pages

-

My3

56 Pages

-

my1b

20 Pages

-

CC

15 Pages

-

J

14 Pages

-

CQ2

51 Pages

-

standard cylinder

84 Pages

-

VFN

6 Pages

-

SY3000

246 Pages

-

SJ3A6

18 Pages

-

1301/IW

14 Pages

-

CHQ/CHDQ

19 Pages

-

AC

95 Pages

-

HAW

4 Pages

-

HAA

3 Pages

-

ZB

24 Pages

-

CRB2

35 Pages

-

CJ1

5 Pages

-

SYJ

62 Pages

-

SJ

78 Pages