Website:

SMC PNEUMATIC

Website:

SMC PNEUMATIC

Group: SMC

Catalog excerpts

Absorbing impact Dampening to meet the high speed requirements of the modern world. Shock absorber: Series RB Coolant resistant type: Series RBL Usable without a stopper nut The strong body can be positioned directly. Short type: Series RBQ A compact style that has been shortened lengthwise Allowable eccentric angle is 5° Suitable for absorption of rotation energy. Usable without a stopper nut The strong body can be positioned directly. Series Variations Shock absorber Automatic adjustment to the most appropriate absorption performance Specially designed orifice can absorb energy comprehensively and most appropriately in many different applications. This ranges from high speed low loads, to load speed high loads; without requiring additional adjustment of the shock absorber. Example of comparison for drag characteristics ■ Drag waveform will vary depending on the operating conditions. Coolant resistant : 2 Hexagon nuts are attached for Series RB and standard models RBQ.

Open the catalog to page 1

Shock Absorber Technical Data: Model Selection Model Selection Step ■ Cylinder stroke at load (Horizontal) ■ Cylinder stroke at load (Downward) ■ Cylinder stroke at load (Upward) ■ Conveyor stroke at load (Horizontal) ■ Free horizontal impact ■ Free dropping impact ■ Rotating impact (With torque) 2. Enumeration of operating conditions Specifications and operational instructions Ensure that the collision speed, thrust, operation cycle, the ambient temperature and atmosphere fall within the specifications. *Be aware of the min. installation radius in the case of rotating impacts. Calculation...

Open the catalog to page 2

Shock Absorber Series RB Cylinder stroke Cylinder stroke Conveyor stroke Free dropping Rotating impact at load (Downward) at load (Upward) at load (Horizontal) impact (With torque) Kinetic energy Thrust energy Absorbed energy impacting object Note 1 ) Collision speed is momentary velocity at which object is impacting against shock absorber. The collision speed is v = 2v when the speed (average speed v) is calculated from the air cylinder's stroke time. Note 2) An "Impact body equivalent mass" is the mass of an impact object without involving thrust, into which an object's total energy has...

Open the catalog to page 3

Thrust Energy of Cylinder Fi S I Operating pressure other than 0.5 MPa: Multiply by the following coefficient. Thrust Energy at Load m g s The graph of corresponding mass of impacting object: At room temperature (20 to 25°C)

Open the catalog to page 4

Shock Absorber Note 1) The maximum energy absorption, the maximum corresponding mass of impacting object and maximum operating frequency are measured at room temperature (20 to 25°C). Note 2) It denotes the values at the maximum energy absorption per one cycle. Max. operating frequency can increase in proportion to energy absorption. Shock absorber Note) RB0604: With cap type is not available. Replacement part no./Cap (Resin part only) RBC rj8 I C Applicable model • Cap cannot be mounted for basic type. Please place an order with cap type from the beginning.

Open the catalog to page 5

Component Parts

Open the catalog to page 6

Shock Absorber Series RB * Other dimensions are the same as the basic type. * Other dimensions are the same as the basic type.

Open the catalog to page 7

Replacement Parts Material: Polyurethane Foot Bracket for Shock Absorber Available for the foot mounting bracket of Series RB. * Order foot brackets separately.

Open the catalog to page 8

Specific Product Precautions 1 Be sure to read before handling. Refer to front matters 42 and 43 for Safety Instructions. Select a model so that the aggregated energy of impact object should not exceed the maximum absorption energy. Otherwise, it could cause changes in properties or result in damaging the shock absorber. 2. Corresponding mass of impacting object Make a model selection, so that the corresponding mass of impacting object does not exceed the allowable range. Pulsation will occur in buffer and deceleration force, thus making it difficult to absorb shock smoothly. Use it in the...

Open the catalog to page 9

Al Specific Product Precautions 2 I Be sure to read before handling. Refer to front matters 42 and 43 for Safety Instructions. Operating Environment When vibrations are applied on impact objects, implement a secure guide on impact objects. 1. Before performing installation, removal, or stroke adjustment, make sure to cut the power supply to the equipment and verify that the equipment has stopped. 2. Installation of protective cover We recommend the protective cover should be installed in the case workers might be getting close during the operation. 3. The rigidity of the mounting frame The...

Open the catalog to page 10

I Specific Product Precautions 3 I Be sure to read before handling. Refer to front matters 42 and 43 for Safety Instructions. 6. Adjust the stopping time through the use of the stopper nut, as Control the stopping time of the impact object by turning the stopper nut in or out (thus changing length "a"). After establishing the stopper nut position, use a hexagon nut to secure the stopper nut in place. S: Shock absorber stroke (Catalog values) 1. Check the mounting nut is not loosen. The shock absorber could become damaged if it is used in a loose 2. Pay attention to any abnormal impact...

Open the catalog to page 11

Shock Absorber: Coolant Resistant Type ments exposed to non-water soluble cutting oil. (Mainly JIS Scraper and rod seal combine to form a double seal enclosure preventing cutting oil from entering inside. Basic type Cap (Resin part only) Note 1) The maximum energy absorption and maximum operating frequency are measured at room Note 2) It denotes the values at the maximum energy absorption per one cycle. Max. operating frequency can increase in proportion to energy absorption. Shock absorber Coolant resistant type thread size/Stroke Cap cannot be mounted for basic type. Please place an order...

Open the catalog to page 12

Shock Absorber: Coolant Resistant Type Series * Other dimensions are the same as the basic type. Note) L, LL and S dimensions of RBL(C)1007/1006 are different from those of RB(C)1007/1006. * Other dimensions are the same as the basic type. Note) L, LL and S dimensions are different from those of RB(C) (except RBL(C)2015). Replacement Parts Material: Polyurethane

Open the catalog to page 13All SMC PNEUMATIC catalogs and technical brochures

-

SYJ300/500/700 Series

62 Pages

-

Vacuum Unit ZK2 Series

60 Pages

-

Air Cylinder CJ2 Series

117 Pages

-

AS-FS Series

36 Pages

-

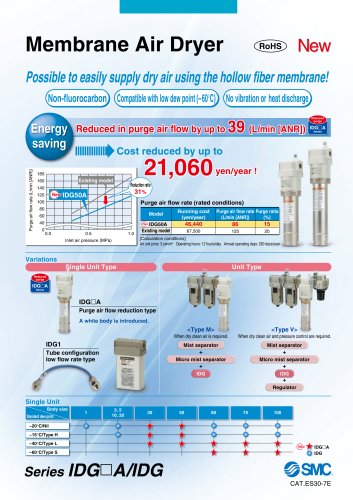

IDF series

12 Pages

-

MHL2 Series

24 Pages

-

JCM Serie

18 Pages

-

EX245 Series

12 Pages

-

Pin Cylinder CJP2/CDJP2/CJP

19 Pages

-

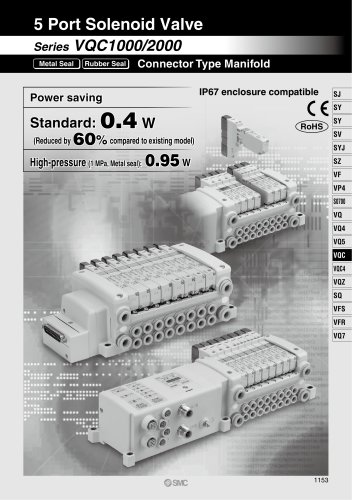

5 Port Solenoid Valve VQC

63 Pages

-

5 Port Solenoid Valve VQ

79 Pages

-

SY

268 Pages

-

5-p0979-0980-hep500

2 Pages

-

5-p0977-0978-aep100

2 Pages

-

5-p0966-0971-lmu

5 Pages

-

5-p0960-0966-alb900

6 Pages

-

5-p0956-0960-ald600

5 Pages

-

5-p0948-0950-al800

3 Pages

-

es70-44c-vx2

52 Pages

-

es50-37-kq2

124 Pages

-

ex-pcw

23 Pages

-

1-p2124-2152-ex510

29 Pages

-

1-p2111-2122-ex500

12 Pages

-

1-p2063-2073-ex260

11 Pages

-

4-p0147-0178-msu-mds

32 Pages

-

es20-230b-crb2

59 Pages

-

1-p1869-1878-vp3145

10 Pages

-

VP300/500/700 series

42 Pages

-

1-p1789-1829-vqz100

41 Pages

-

1-p1727-1788-syj300

62 Pages

-

5 Port Solenoid Valve S0700

111 Pages

-

5 Port Solenoid Valve VF

59 Pages

-

5 Port Solenoid Valve SV

127 Pages

-

VH

9 Pages

-

CUJ

41 Pages

-

AL

3 Pages

-

kj mm

9 Pages

-

AQ

4 Pages

-

SY3000/5000-X13

2 Pages

-

Series MB

24 Pages

-

Series LES

23 Pages

-

Series LEFB

16 Pages

-

Series PF3W

28 Pages

-

Series IDG?A/IDG

56 Pages

-

Floating Joint

7 Pages

-

Series IZS40/41/42

32 Pages

-

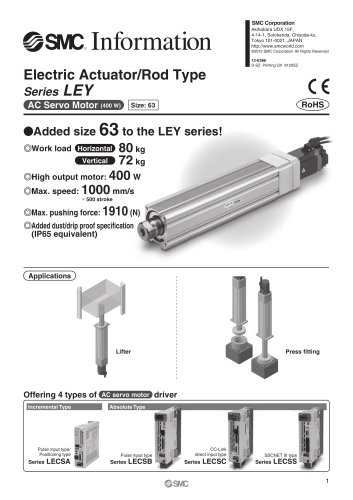

Series LEY

7 Pages

-

Series VHS

12 Pages

-

Series CY1S

28 Pages

-

SeriesCQ2/CQS/CQ

4 Pages

-

In-line Air Filter

12 Pages

-

5 Port Solenoid Valve

60 Pages

-

Series CQ2/CQS

2 Pages

-

AS series

2 Pages

-

corporate guide

13 Pages

-

ZP

69 Pages

-

ZFA

14 Pages

-

ZA

13 Pages

-

MHF

32 Pages

-

MHZ

68 Pages

-

CRB

44 Pages

-

D

117 Pages

-

CEP

44 Pages

-

RSK

30 Pages

-

CLK

51 Pages

-

MK

20 Pages

-

GLJ

65 Pages

-

MGJ

7 Pages

-

Mx

36 Pages

-

MXH

18 Pages

-

My3

56 Pages

-

my1b

20 Pages

-

CC

15 Pages

-

J

14 Pages

-

CQ2

51 Pages

-

standard cylinder

84 Pages

-

VFN

6 Pages

-

SY3000

246 Pages

-

SJ3A6

18 Pages

-

1301/IW

14 Pages

-

CHQ/CHDQ

19 Pages

-

AC

95 Pages

-

HAW

4 Pages

-

HAA

3 Pages

-

ZB

24 Pages

-

CRB2

35 Pages

-

CJ1

5 Pages

-

SYJ

62 Pages

-

SJ

78 Pages