Website:

SMC PNEUMATIC

Website:

SMC PNEUMATIC

Group: SMC

Catalog excerpts

Mechanically Jointed Rodless Cylinders Basic short type (Rubber bumper) Bore sizes Basic standard type (Air cushion) Bore sizes Slide bearing guide type (Air cushion) Series Variations Long stroke Shock Absorber "Helical Insert threads" Holder mounting bracketNo,e) Copper Free Shock Absorber Soft Type Series RJ Installed Cylinder (-XB22 spec.) added • Soft stopping enabled at stroke end. • Two types of shock absorbers are selectable according to operating environment.

Open the catalog to page 1

High functionality with reduced height and length Mechanically Jointed Rodless Cylinders Basic short type (Rubber bumper) Basic standard type Loading Capacity Work pieces can be loaded directly on the work table Overall length (Z) reduced by mm at the maximum MY3A (with rubber bumper) _ Overall length (Z + Stroke) Height (H) reduced by 36% at the maximum Weight reduced by 55% at the maximum

Open the catalog to page 2

Floating Bracket Easy connection with external guide. Vertical and lateral mounting is possible. (Page 24) Stroke Adjustment Unit (MY3A/3B) (MY3B/3M) Side Support The cylinder tube can be fixed from the upper or lower side. (Page 23, 37) Auto Switch Centralized Piping Integrated piping in the head cover is possible. (Page 20, 21, 35) Can be mounted on both sides from the front direction. The uniquely designed piston shape enables reduction of the height and length as well as practical arrangement of the common piping passages, cushion mechanism and positioning mechanism. This has achieved...

Open the catalog to page 3

Model Selection The following are steps for selecting the MY3 series which is best suited to your application. Guideline for Tentative Model Selection O Most suitable O Suitable A Usable X Not recommended Note 1 ) The table accuracy means the amount of table deflection when a moment Is applied. Note 2) Travelling parallelism Is not guaranteed for this cylinder. Please consult with SMC If the travelling parallelism or stroke Intermediate position needs to be precise. Selection Flow Chart When an external guide is used, the selection confirmation of the guide capacity should follow the...

Open the catalog to page 4

Model Selection Seríes MY3 Maximum operating speed Reduction circuits or shock absorbers may be necessary. If the driven object is fast, or the weight is large, the cylinder cushion alone may not be able to absorb the Impact. In this case, install a reduction circuit before the cushion, or Install an external shock absorber to reduce the Impact. Please check the machine's rigidity as well. * External shock absorbers must meet the characteristics listed on page 11. Cylinders may be dam- aged If shock absorbers that do not have the recommended characteristics are used. Stroke positioning...

Open the catalog to page 5

Types of Moment and Load Weight Applied to Rodless Cylinders Multiple moments may be generated depending on the mounting orientation, load and position of the center of gravity. Load Weight and Static Moment Note) nu is a weight movable by thrust. Use 0.3 to 0.7 times the thrust (differs depending on the operating speed) as a guide for actual Dynamic Moment Note) Regardless of the mounting orientation, dynamic moment is calculated with the formulae above. Calculation of Guide Load Factor 1. Maximum load weight (1 ), static moment (2), and dynamic moment (3) (at the time of impact with...

Open the catalog to page 6

Model Selection Series MY3 Calculation of Guide Load Factor 1 Operating Conditions Cylinder • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Average operating speed υa • • • • • • • • • • Mounting direction • • • • • • • • • • • • • • • • • • • • • • • Cushion • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Mounting Direction MY3A25-500 300 mm/s Horizontal mounting Rubber bumper (δ = 4/100) 1. Horizontal z mounting 2. Wall mounting y Page 26 x y 3. Ceiling mounting z x W: Work piece (0.8 kg) 4. Vertical mounting x Page 2 z y x y z...

Open the catalog to page 7

Series MY3 Calculation of Guide Load Factor 4 Calculation of Load Factor for Dynamic Moment Equivalent load FE at impact 4 FE = 1.4υa x δ x m x g = 1.4 x 300 x —— x 0.8 x 9.8 = 131.7 (N) 100 M1E: Moment FE M1E Z M1E max (from r of graph MY3A ⁄ M1 where 1.4υa = 420 mm/s) = 2.85 (NႧm) • • • • • • • • • • • • • • 1 1 M1E = —— x FE x Z = —— x 131.7 x 20 x 10-3 = 0.88 (NႧm) 3 3 Load factor 4 = M1E ⁄ M1E max = 0.88 ⁄ 2.85 = 0.31 M1 M3 M3E: Moment Y M3E max (from t of graph MY3A ⁄ M3 where 1.4υa = 420 mm/s) = 0.95 (NႧm) • • • • • • • • • • • • • • • • • • • • 1 1 M3E = —— x FE x Y = —— x 131.7 x...

Open the catalog to page 8

Model Selection Seríes MY3 Mounting of Fitting and Speed Controller When the stroke adjustment unit is used with MY3B and MY3M, the fittings mountable on the front or back port will be limited to those lis- In such cases, since direct mount type speed controllers cannot be mounted, use in-line type speed controllers. (Except Mounting (Mounting a male connector) Stroke adjustment unit Refer to Best Pneumatics No. 6 for the details of fittings and speed controllers. Direct Mount Type Speed Controller Elbow/Universal type In-line type

Open the catalog to page 9

Specific Product Precautions Be sure to read before handling. Refer to back cover for the Safety Instructions, "Handling Precautions for SMC Products" (M-E03-3) and the Operation Manual for Actuators and Auto Switches Precautions. 1. When applying a load directly, set the design so that all the mounting threads on the slide table's upper surface are used. Parts have been made smaller to achieve a compact size. If only some of the threads are used when mounting the load, the impact that results from the operation may cause extreme- ly concentrated stress or disfiguration and may negatively...

Open the catalog to page 10All SMC PNEUMATIC catalogs and technical brochures

-

SYJ300/500/700 Series

62 Pages

-

Vacuum Unit ZK2 Series

60 Pages

-

Air Cylinder CJ2 Series

117 Pages

-

AS-FS Series

36 Pages

-

IDF series

12 Pages

-

MHL2 Series

24 Pages

-

JCM Serie

18 Pages

-

EX245 Series

12 Pages

-

Pin Cylinder CJP2/CDJP2/CJP

19 Pages

-

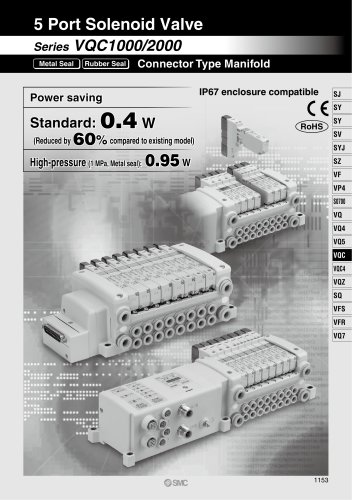

5 Port Solenoid Valve VQC

63 Pages

-

5 Port Solenoid Valve VQ

79 Pages

-

SY

268 Pages

-

5-p0979-0980-hep500

2 Pages

-

5-p0977-0978-aep100

2 Pages

-

5-p0966-0971-lmu

5 Pages

-

5-p0960-0966-alb900

6 Pages

-

5-p0956-0960-ald600

5 Pages

-

5-p0948-0950-al800

3 Pages

-

es70-44c-vx2

52 Pages

-

es50-37-kq2

124 Pages

-

ex-pcw

23 Pages

-

1-p2124-2152-ex510

29 Pages

-

1-p2111-2122-ex500

12 Pages

-

1-p2063-2073-ex260

11 Pages

-

4-p0147-0178-msu-mds

32 Pages

-

es20-230b-crb2

59 Pages

-

1-p1869-1878-vp3145

10 Pages

-

VP300/500/700 series

42 Pages

-

1-p1789-1829-vqz100

41 Pages

-

1-p1727-1788-syj300

62 Pages

-

5 Port Solenoid Valve S0700

111 Pages

-

5 Port Solenoid Valve VF

59 Pages

-

5 Port Solenoid Valve SV

127 Pages

-

VH

9 Pages

-

CUJ

41 Pages

-

AL

3 Pages

-

kj mm

9 Pages

-

AQ

4 Pages

-

SY3000/5000-X13

2 Pages

-

Series MB

24 Pages

-

Series LES

23 Pages

-

Series LEFB

16 Pages

-

Series PF3W

28 Pages

-

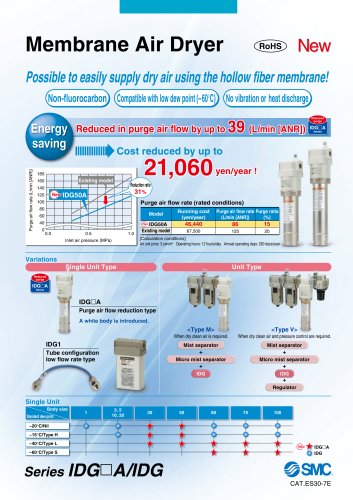

Series IDG?A/IDG

56 Pages

-

Floating Joint

7 Pages

-

Series IZS40/41/42

32 Pages

-

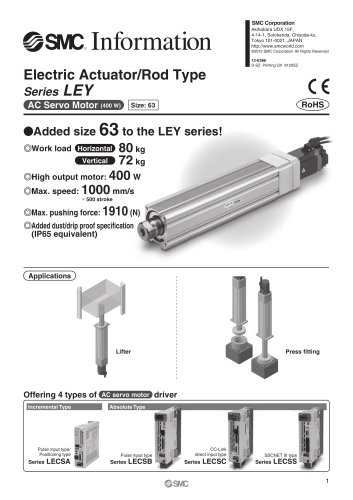

Series LEY

7 Pages

-

Series VHS

12 Pages

-

Series CY1S

28 Pages

-

SeriesCQ2/CQS/CQ

4 Pages

-

In-line Air Filter

12 Pages

-

5 Port Solenoid Valve

60 Pages

-

Series CQ2/CQS

2 Pages

-

AS series

2 Pages

-

corporate guide

13 Pages

-

ZP

69 Pages

-

ZFA

14 Pages

-

ZA

13 Pages

-

MHF

32 Pages

-

MHZ

68 Pages

-

CRB

44 Pages

-

D

117 Pages

-

RB

23 Pages

-

CEP

44 Pages

-

RSK

30 Pages

-

CLK

51 Pages

-

MK

20 Pages

-

GLJ

65 Pages

-

MGJ

7 Pages

-

Mx

36 Pages

-

MXH

18 Pages

-

my1b

20 Pages

-

CC

15 Pages

-

J

14 Pages

-

CQ2

51 Pages

-

standard cylinder

84 Pages

-

VFN

6 Pages

-

SY3000

246 Pages

-

SJ3A6

18 Pages

-

1301/IW

14 Pages

-

CHQ/CHDQ

19 Pages

-

AC

95 Pages

-

HAW

4 Pages

-

HAA

3 Pages

-

ZB

24 Pages

-

CRB2

35 Pages

-

CJ1

5 Pages

-

SYJ

62 Pages

-

SJ

78 Pages