Website:

SMC PNEUMATIC

Website:

SMC PNEUMATIC

Group: SMC

Catalog excerpts

Booster Lube Standard Specifications Centralized control of multi-point lubrication Stable oil feeding with a micromist pressure that is higher than that of the main air passage can be supplied. This difference is used as the mist generating pressure differential. Thus, the pressure drop in the main air passage is minimized. supplied by merely adjusting the mist generating pressure differential. opening and closing the oil filler plug without stopping the air line. Port (Bypass lubrication adapter) Port size (Body) of micromist can be checked from the oil filler port. 0.4 to 1.0 MPa Operating pressure differential range 0.05 to 0.2 MPa Bowl capacity between levels (cm3) 5000 Turbine oil Class 1 (With no additives), ISO VG32 Recommended lubricant Operating pressure range 5 to 50°C Epoxy resin with glass fiber, Polycarbonate Ambient and fluid temperature Bowl material Accessory (Option) Part No. Part no. Bypass lubrication adapter Standard accessory Ball valve Ball valve Float switch Note) Float switch specifications Voltage Max. contact capacity Max. contact current Contact Level indication 1a, 1b Bottom limit indication 0 0 Float switch (Option) Booster lube Operation control signal Body size Port size None Rc 1 Rc 2 3 inch flange None 1b (Without oil ON) 1a (Without oil OFF) Proof pressure

Open the catalog to page 1

Piping Example Strainer Series AF-X2230 Solenoid valve Metal seal Ball valve Bypass lubrication adapter Ball valve Main line filter Series AFF Solenoid valve Rubber seal Operation Control Method As shown in the diagram below, reverse the position of the function plate of the switching valve for operation control, and place it in the NO position or in the unmarked position. When the control signal is input, select the state of the operation or the stopping of the Booster Lube. This unit uses a booster to generate a mist generating pressure differential. Therefore, the booster consumes and...

Open the catalog to page 2

Booster Lube Setting of Mist Generation Pressure Differential Procedure 1. Obtain the air consumption flow rate in the downstream of the Booster Lube. 2. Obtain the necessary mist generation pressure differential from data(B). Data(B) Flow — Mist Generation Pressure Differential Precautions Be sure to read before handling. Refer to front matter 43 for Safety Instructions and pages 365 to 369 for Precautions on every series. Warning 1. Epoxy resin containing glass fiber and polycarbonate is used in some parts of the Booster Lube. The Booster Lube cannot be used in an environment or in a...

Open the catalog to page 3

Circuit Manual switching valve for confirmation of mist generation pressure differential Lubrication plug 2 port valve Oil tank Mist generation nozzle Pressure differential Relay valve Switching valve for adjustment valve operation control Description Top cover Bottom cover Replacement Parts Material Aluminum casted Aluminum casted Description 3 port switching valve (for operation control) Relay valve Pressure gauge Diaphragm assembly Valve assembly NLP seal PNY seal Wear ring O-ring Bowl assembly Lubrication plug assembly NBR NBR Cloth-inserted phenol aldehyde resin NBR Glass...

Open the catalog to page 4

Booster Lube Pressure differential adjustment screw Relay valve Switching valve for operation control Manual switching valve for confirmation of mist generation pressure differential Lubrication plug Bypass Lubrication Adapter ALBA90-10/-20 From booster lube Port size Rc 1/2 From booster lube

Open the catalog to page 5

Related Product Strainer At the terminal of an air pressure line in which a Booster Lube is used, install a strainer (filtration rate of 5 µm) upstream from a metal seal solenoid valve, which is susceptible to dust. Mounting orientation is upward. 4xK Bracket mounting thread

Open the catalog to page 6All SMC PNEUMATIC catalogs and technical brochures

-

SYJ300/500/700 Series

62 Pages

-

Vacuum Unit ZK2 Series

60 Pages

-

Air Cylinder CJ2 Series

117 Pages

-

AS-FS Series

36 Pages

-

IDF series

12 Pages

-

MHL2 Series

24 Pages

-

JCM Serie

18 Pages

-

EX245 Series

12 Pages

-

Pin Cylinder CJP2/CDJP2/CJP

19 Pages

-

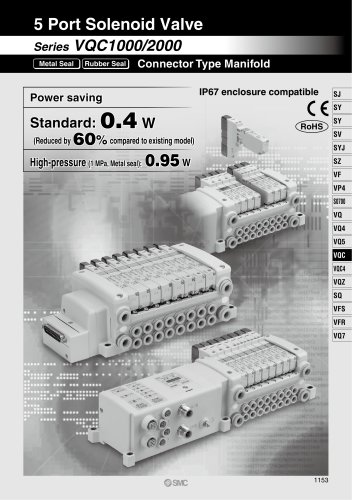

5 Port Solenoid Valve VQC

63 Pages

-

5 Port Solenoid Valve VQ

79 Pages

-

SY

268 Pages

-

5-p0979-0980-hep500

2 Pages

-

5-p0977-0978-aep100

2 Pages

-

5-p0966-0971-lmu

5 Pages

-

5-p0956-0960-ald600

5 Pages

-

5-p0948-0950-al800

3 Pages

-

es70-44c-vx2

52 Pages

-

es50-37-kq2

124 Pages

-

ex-pcw

23 Pages

-

1-p2124-2152-ex510

29 Pages

-

1-p2111-2122-ex500

12 Pages

-

1-p2063-2073-ex260

11 Pages

-

4-p0147-0178-msu-mds

32 Pages

-

es20-230b-crb2

59 Pages

-

1-p1869-1878-vp3145

10 Pages

-

VP300/500/700 series

42 Pages

-

1-p1789-1829-vqz100

41 Pages

-

1-p1727-1788-syj300

62 Pages

-

5 Port Solenoid Valve S0700

111 Pages

-

5 Port Solenoid Valve VF

59 Pages

-

5 Port Solenoid Valve SV

127 Pages

-

VH

9 Pages

-

CUJ

41 Pages

-

AL

3 Pages

-

kj mm

9 Pages

-

AQ

4 Pages

-

SY3000/5000-X13

2 Pages

-

Series MB

24 Pages

-

Series LES

23 Pages

-

Series LEFB

16 Pages

-

Series PF3W

28 Pages

-

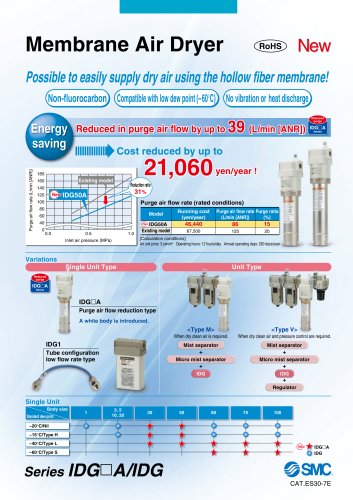

Series IDG?A/IDG

56 Pages

-

Floating Joint

7 Pages

-

Series IZS40/41/42

32 Pages

-

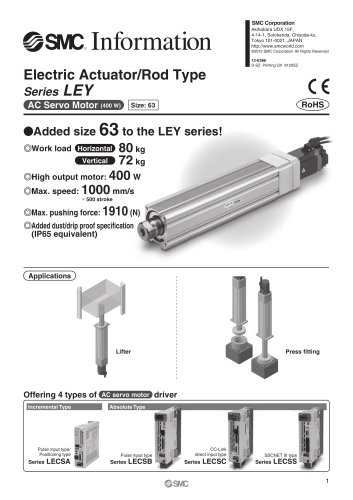

Series LEY

7 Pages

-

Series VHS

12 Pages

-

Series CY1S

28 Pages

-

SeriesCQ2/CQS/CQ

4 Pages

-

In-line Air Filter

12 Pages

-

5 Port Solenoid Valve

60 Pages

-

Series CQ2/CQS

2 Pages

-

AS series

2 Pages

-

corporate guide

13 Pages

-

ZP

69 Pages

-

ZFA

14 Pages

-

ZA

13 Pages

-

MHF

32 Pages

-

MHZ

68 Pages

-

CRB

44 Pages

-

D

117 Pages

-

RB

23 Pages

-

CEP

44 Pages

-

RSK

30 Pages

-

CLK

51 Pages

-

MK

20 Pages

-

GLJ

65 Pages

-

MGJ

7 Pages

-

Mx

36 Pages

-

MXH

18 Pages

-

My3

56 Pages

-

my1b

20 Pages

-

CC

15 Pages

-

J

14 Pages

-

CQ2

51 Pages

-

standard cylinder

84 Pages

-

VFN

6 Pages

-

SY3000

246 Pages

-

SJ3A6

18 Pages

-

1301/IW

14 Pages

-

CHQ/CHDQ

19 Pages

-

AC

95 Pages

-

HAW

4 Pages

-

HAA

3 Pages

-

ZB

24 Pages

-

CRB2

35 Pages

-

CJ1

5 Pages

-

SYJ

62 Pages

-

SJ

78 Pages