Website:

SKF Lincoln Automatic Lubrication Systems

Website:

SKF Lincoln Automatic Lubrication Systems

Group: SKF

Catalog excerpts

Installation and operation manual CLK lubrication system Airless oil projection system for conveyor roller chain lubrication Form number Read manual prior to installation or use of this product. Keep manual nearby for future reference.

Open the catalog to page 1

Training courses In order to provide a maximum of safety and economic viability, SKF carries out detailed training courses. It is recommended that the training courses are attended. For more information please contact the SKF Service Center or the local SKF representative. In accordance with the EU Machine Directive 2006/42/CE, the installation and operation instructions are an integral part of a lubrication system and must be kept close to the equipment for future reference. The installation and operation instructions were drafted in compliance with the applicable standards and rules...

Open the catalog to page 2

Contents Imprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Training courses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Disclaimer . . . . . . . . . . . . . . . . . . . ....

Open the catalog to page 3

General • rotational direction arrows • fluid connection labels, etc. Meaning of symbols and corresponding information must be respected and remain perfectly legible. It is essential to read these instructions thoroughly and to respect the safety instructions given. In this manual, the symbols and safety wordings shown on this page are intended to communicate a particular risk to persons, material assets, or the environment. All safety instructions must be respected by person exposed to these risks. The safety instructions must be communicated to all other persons. Instructions attached...

Open the catalog to page 4

Information concerning the EC Declaration of Incorporation EC Declaration of Incorporation in accordance with EC-Machinery Directive 2006/42/EC, Appendix II Part B The manufacturer SKF France SAS, 204, Bld Charles de Gaulle, B.P. 239 – 37540 St-Cyr-sur-Loire – FRANCE, declares herewith the conformity of the partly completed machine Designation: Type: Order No.: Year of construction: Grease injection lubrication system for chains CLK see ID plate see ID plate with the following essential health and safety requirements of the EC Machinery Directive 2006/42/EC when released on the market....

Open the catalog to page 5

1.3 Qualified technical personnel Only qualified technical personnel may install, operate, maintain, and repair the products described in the manual. Qualified technical personnel are persons who have been trained, assigned and instructed by the operator of the installation. These persons are considered capable of such tasks due to their education, training, and experience with valid standards, conditions, accident prevention regulations in effect, and installation conditions. They should be able to carry out the required tasks and to recognize – and thus avoid – any dangers that might...

Open the catalog to page 6

1.5 System pressure hazard points. Product may only be used following the specifications, technical data and limits stated in this manual. Other use or use beyond this purpose is considered unintended. System pressure The product is pressurized during operation. The product must therefore be depressurized before starting assembly, maintenance, or repair work A usage of the product differing from the aforementioned conditions and stated purpose is strictly prohibited. Particularly prohibited are: • use in an explosive atmosphere (according to guideline ATEX 2014/34/EU) • use without...

Open the catalog to page 7

NOTE The manufacturer of the chain to be lubricated will specify the lubricant requirements for each point to be lubricated. You must make sure that the required quantity of lubricant is provided to the relevant lubricating point. If a lubricating point is insufficiently lubricated, the bearing may become damaged or jammed. 2.1 General NOTE All SKF products must only be used for their intended purpose and in accordance with the specifications of the installation instructions for the product in question. While the machinery/bearing manufacturer usually specifies lubricants, it is the...

Open the catalog to page 8

2.5 Danger relating to lubricants CAUTION Different lubricants must not be mixed together. Doing so can cause damage and require extensive cleaning of the products/centralized lubrication system. To prevent confusion, we recommend that you attach information indicating the lubricant to be used on the lubricant reservoir. CAUTION Centralized lubrication systems must be absolutely leakfree. Leaking centralized lubrication systems can cause a slip hazard. When performing installation, maintenance, and repairs test the centralized lubrication system for leaks. Leaky parts of the centralized...

Open the catalog to page 9

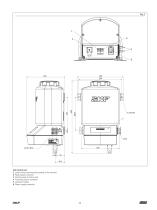

3.3.1 Central unit The central unit († fig. 1) is a compact group comprising a reservoir mounted on a pump housing. The pump housing houses an electromagnetic pump and an integrated control unit. The control unit can be controlled and monitored from the control panel located on the housing front side. For more information on the control unit, refer to the section 6.2 Control unit. The unit electrical connections are located under the rear part of the housing. It comprises three connectors (power supply, proximity sensor and fault outputs). A fourth connector can be optionally added to check...

Open the catalog to page 10

CLK central unit 1 Level-contact connector (according to the version) 2 Fault output connector 3 Control panel of control unit 4 Proximity sensor connector 5 Lubricant outlets 6 Power supply connector

Open the catalog to page 11

Fig. 2 Projection nozzles with proximity sensor mounted on a support Connector M12 (with 5 m cable) Inductive proximity sensor

Open the catalog to page 12

A lubricant film is formed at the friction zones. It reduces the temperature rising and therefore the part wear. In addition, it provides extra protection against external pollution, by preventing the foreign matter (dust, particles ...) to penetrate between the different parts. The CLK-type lubrication systems for conveyor chains generally comprise a piston pump with electromagnetic control, an oil reservoir and a control unit. The lubricant is supplied to the lubrication points by means of projection nozzles. Friction zones The chains have a large number of friction zones that should be...

Open the catalog to page 13All SKF Lincoln Automatic Lubrication Systems catalogs and technical brochures

-

SKF Compact greaser

8 Pages

-

Pump unit PPS30

4 Pages

-

ECP Product brochure

8 Pages

-

Product series 143 brochure

24 Pages

-

Wire rope lubrication system

8 Pages

-

Single- and Multi-circuit Pumps

16 Pages

-

LubriLean brochure

4 Pages

-

1154 flyer

2 Pages

-

EDL1 product brochure

4 Pages

-

DSA product brochure

4 Pages

-

DSC3 product brochure

4 Pages

-

DSB product brochure

4 Pages

-

HCC product brochure

2 Pages

-

LMC 301 product brochure

8 Pages

-

SFZM product brochure

4 Pages

-

SP/SMB14 product brochure

8 Pages

-

SP/SMB13 product brochure

8 Pages

-

SMBM product brochure

18 Pages

-

Safeflow product brochure

4 Pages

-

SMT 1 product brochure

8 Pages

-

LP2 / LPC product brochure

8 Pages

-

PSG product brochure

36 Pages

-

VP product brochure

20 Pages

-

VPK product brochure

20 Pages

-

VPB product brochure

12 Pages

-

SPVS product brochure

8 Pages

-

SKF Maxilube Solution

8 Pages

-

SGA/SG product brochure

6 Pages

-

SLC product brochure

12 Pages

-

SL-6 product brochure

4 Pages

-

SL-32HV product brochure

2 Pages

-

310 series product brochure

4 Pages

-

BPH product brochure

4 Pages

-

Lubrigun product brochure

15 Pages

-

EOP2 product brochure

2 Pages

-

MPB product brochure

2 Pages

-

FK product brochure

12 Pages

-

VectoLub product brochure

30 Pages

-

Gear Pump Units brochure

12 Pages

-

P502 product brochure

2 Pages

-

LubriLean product brochure

16 Pages

-

P603S product brochure

8 Pages

-

P212 product brochure

2 Pages

-

P205/ P215 product brochure

2 Pages

-

MKx series product brochure

24 Pages

-

Product Series OLA, MV and 161

28 Pages

-

CLK product brochure

8 Pages

-

Pulse meter IPM

4 Pages

-

Gear wheel indicator SFZM

4 Pages

-

Oil conditioning unit OCU

4 Pages

-

LFC 5000

4 Pages

-

SSV-D

2 Pages

-

Improved Centro-Matic SL-11

12 Pages

-

SL-V XL

4 Pages

-

12-volt Reel 'n F

2 Pages

-

New 90-lb. Reservoir

12 Pages

-

HTL 429

4 Pages

-

Lincoln

8 Pages

-

AC FlowMaster

12 Pages

-

EOS

2 Pages

-

LFR Series

4 Pages

-

Hand Vacuum Pumps

6 Pages

-

Pumps PMV Pump Family

16 Pages