Website:

SITEMA

Website:

SITEMA

Catalog excerpts

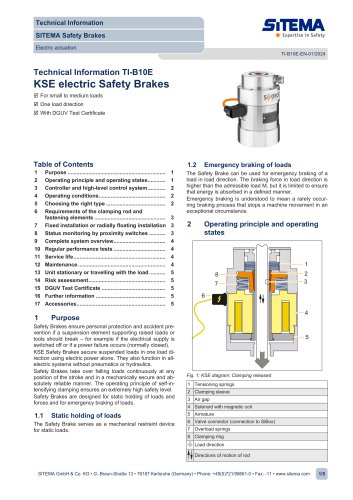

SiTEMA ■ Expertise in Safety Technical Information SITEMA Safety Catchers Hydraulic or pneumatic actuation Technical Information TI-A10 Safety Catchers 0 high holding force by self-intensifying clamping 0 hydraulic or pneumatic actuation 0 officially certified by DGUV as restraint device for presses, injection moulding machines, rubber and plastics machines For further information on technical data and optional accessories, please see: • “Technical Data Sheet TI-A11” (hydraulic pressure versions: series KR, K) • “Technical Data Sheet TI-A12” (pneumatic pressure versions: series KRP) • “Technical Data Sheet TI-A13” (hydraulic tensile versions: series KR/T, K/TA) • “Technical Data Sheet TI-A14” ("pneumatic tensile versions: series KRP/T) • “Technical Data Sheet TI-A20” (spring bases for pressure versions) • “Technical Data Sheet TI-A21” (spring bases for tensile versions) • “Technical Data Sheet TI-A30” (flanges for Safety Catchers and spring bases) For information on the DGUV approval and EC type-examination certificate, please see: • “EC Type-examination Certificate TI-A40” A detailed description of control, mounting and performance test of the SITEMA Safety Catchers can be found in: • “Operating Manual BA-A11” (hydraulic versions) • “Operating Manual BA-A12” (pneumatic versions) 1 Purpose Safety Catchers are used where protection of personnel and accident prevention must be achieved in connection with raised loads or tools in case of failure of load-bearing machine parts. This may e.g. be a leakage or breakdown of a hydraulic or pneumatic pressure system. Safety Catchers catch falling masses infinitely variable at any position of the stroke, in a mechanically secure and absolutely reliable manner. The design principle of the self-intensifying clamping ensures an extremely high safety level. Safety Catchers serve as mechanical restraint devices for static loads. For this static holding, the Safety Catcher is certified according to the testing principle GS-HSM-02 of the DGUV (testing and certification body of the statutory accident insurance and prevention institution in Germany). For further information see “EC type-examination certificate TI-A40”, internet download: www.sitema.com. 2 Function SITEMA Safety Catchers release by applying hydraulic or pneumatic pressure and clamp at pressure loss. The kinetic energy of the falling mass is then used to generate the holding force. The piston or clamping rod (1) is surrounded by the housing (2) in which several wedged clamping jaws (3), each with one slide lining (4) and one brake lining (5), are assembled. When pressure (p) is applied to the plungers (8), the clamping jaws are held in a raised position so that the rod can move freely. The springs (6) are compressed in this position. SITEMA GmbH & Co. KG . G.-Braun-StraUe 13 . D-76187 Karlsruhe . Phone: +49(0)721/98661-0 . Fax: -11 .

Open the catalog to page 1

2.1 Secure the load The Safety Catcher secures the load as soon as pressure is released from the plungers (8), Fig. 1. Then the action of the springs (6), Fig. 1 causes the clamping jaws (3), Fig. 1 to clamp the rod (1), Fig. 1 firmly, whereby an initial friction contact between rod and clamping sleeve is achieved (contact condition). At this point, the Safety Catcher secures the load but has not yet taken the load. 2.2 Take the load The holding force, however, is not built up until the rod has been moved by the load. Due to the self-intensifying static friction at the rod, the clamping...

Open the catalog to page 2

Technical Information SITEMA Safety Catchers Hydraulic or pneumatic actuation TI-A10-EN-01/2019 H Control and function monitoring are the responsibility of 4.2 Actuation with a 3/2-way valve In most applications an actuation as suggested in Fig. 2 is used. During every operational cycle, the 3/2-way valve is actuated electrically and releases the Safety Catcher. In all other operational conditions, as well as in cases of power failure, pressure line breakage, emergency stop, etc. the Safety Catcher becomes effective, secures the rod and/or stops the load. If necessary the valve can also be...

Open the catalog to page 3

7 Service life When estimating service life, a distinction is made between the following categories of stress: 1. Stress when securing the load When securing a stationary load (see Chapter 2.2.1 “Secure the load”), the occurring material stresses are negligible and can be withstood millions of times over. 2. Stress when taking the load When taking up the load (see Chapter 2.2.2 “Take the load”, for example in the event of leakage or a line break,), the Safety Catcher may reach the maximum holding force. The design forces and material stresses then occur. The rod does not slip when this...

Open the catalog to page 4

Technical Information SITEMA Safety Catchers Hydraulic or pneumatic actuation TI-A10-EN-01/2019 13 Attachment Overview of attachment options for PRESSURE and TENSILE versions Safety Catchers can be integrated into the machine as stationary units or as mobile units moving with the load to be secured. When choosing the right series, consider the load that acts on the rod and the Safety Catcher. In the case of PRESSURE versions, the load presses the Safety Catcher onto the machine frame. The load is transferred via the mounting surface of the Safety Catcher into the machine frame. PRESSURE...

Open the catalog to page 5

13.1 Attachment options for PRESSURE versions There are various ways to attach the Safety Catchers series KR, KRP and K. In any case, it must be ensured that no side load can be induced due to tolerances in dimensions or angular alignment relative to other guiding means. If the Safety Catcher is directly mounted to a cylinder head, it usually is properly centered to the rod. In all other setups either the rod or the body of the Safety Catcher must not be rigidly fixed but mounted floating with enough radial clearance. Four basic options are illustrated below, using hydraulic presses as an...

Open the catalog to page 6All SITEMA catalogs and technical brochures

-

electric Safety Brake linear

2 Pages

-

PowerStroke SITEMA

9 Pages

-

SITEMA_Flyer_2020

2 Pages

-

TI-S10 Safety Locks

4 Pages

-

TI-P30

1 Pages

-

Dimensions, type KRG

1 Pages

-

Dimensions, type KRP/T

1 Pages

-

Dimensions, type KRP

1 Pages

-

Dimensions, type KR, K

2 Pages

-

SITEMA Safety Catchers

2 Pages

-

SITEMA Locking Units KFH

6 Pages

-

STB10 Rod Attachment STB

3 Pages

-

SITEMA Applications

2 Pages

-

F60 Dimensions, type KFHA

6 Pages

-

Z10 - Auto Bleeder

3 Pages

-

SITEMA Safety Locks KRG

1 Pages

-

SITEMA company

15 Pages

-

Locking Units KFPC

3 Pages

-

Locking units series KFPA

4 Pages