Website:

SITEMA

Website:

SITEMA

Catalog excerpts

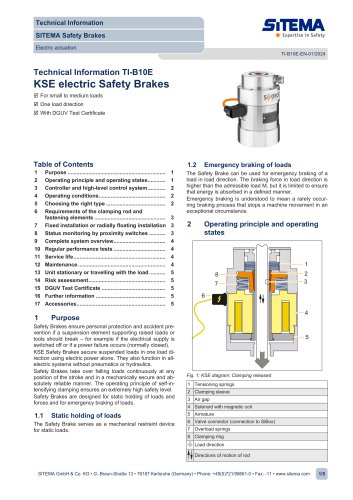

Technical Information TI-P11 SITEMA PowerStroke Mould closing devices series FSK 0 drive system for powerful forces on a short stroke 0 hydraulic actuation 0 closing force up to 200 tonnes A detailed description regarding control and use of the SITEMA PowerStroke is given in the “Assembly Instructions MA-P11". 1 Function The mould closing device SITEMA PowerStroke clamps and actuates a rod in one direction (closing direction). A force proportional to the operating pressure is exerted to the rod by friction. 2 Applications The SITEMA PowerStroke series FSK with its integrated short stroke cylinder is typically used in: • blow moulding to close and press the mould • injection die moulding to close and generate the closing force • other applications requiring powerful forces on a short stroke Application example: schematic compression moulding machine with 4 x SITEMA PowerStroke series FSK 1. Clamping is released; the rod is free; the drive is closing the mould. 3. The PowerStroke executes the closing stroke. SITEMA GmbH & Co. KG . G.-Braun-StraRe 13 . D-76187 Karlsruhe . Phone: +49(0)721/98661-0 . Fax: -11 . www.sitema.com

Open the catalog to page 1

Technical Information SITEMA PowerStroke FSK Locking, actuating and releasing by hydraulic pressure TI-P11-EN-01/2017 The following function description specifies the typical case if the SITEMA PowerStroke is mounted to the moving machine element. Then, the rod acts as a connection to the stationary machine element. The closing direction is shown as it would appear in this case. Alternatively, it is also possible to mount the SITEMA PowerStroke to the stationary machine element. Then, the rod is moving. In this case, the closing direction is reversed. SITEMA PowerStroke is about to clamp...

Open the catalog to page 2

J In no situation may pressure be applied to both pressure ports L and K at the same time. To release the clamping, hydraulic pressure at pressure port K must be relieved and pressure must be applied to pressure port L. As a result, the housing first moves back a little bit (previously-executed closing stroke) and then the clamping gets released. 4 Installation prerequisites 4.1 Design of the rod The SITEMA PowerStroke will operate correctly only if the rod has a suitable surface: • ISO tolerance field f7 or h6 • induction hardened min. HRC 56, surface hardening depth: 0 up to 30 mm: min. 1...

Open the catalog to page 3

Technical Information SITEMA PowerStroke FSK Locking, actuating and releasing by hydraulic pressure TI-P11-EN-01/2017 The rod may not leave the clamping unit during operation. However, special designs which allow the rod to be removed and inserted with each stroke are possible. In this case, the rod may only be inserted in the released state (proximity switch signal 2 is active) through the centre ring. Before the rod may be clamped, it has to be ensured, that the rod is inserted to at least the “minimum insertion depth” indicated in the special design’s specifications. 2. During the...

Open the catalog to page 4

SITEMA PowerStroke FSK Locking, actuating and releasing by hydraulic pressure SiTEMA ■ Expertise in Safety Pressure port K “closing stroke” see O © Pressure port L “release” see 0 © Pressure port V “supply pressure” see @ © Holder for proximity switch 2, signal “clamping released” see O © Holder for proximity switch 3, signal “stroke limit reached” see O Abb. 5: Dimensions SITEMA PowerStroke series FSK O Proximity switch holders are provided for standard inductive proximity switches (M12 x 1, nominal switching distance 2 mm, flush mountable, NOC; except FSK 45 to FSK 100 need M8x1 with a...

Open the catalog to page 5All SITEMA catalogs and technical brochures

-

electric Safety Brake linear

2 Pages

-

PowerStroke SITEMA

9 Pages

-

SITEMA_Flyer_2020

2 Pages

-

TI-S10 Safety Locks

4 Pages

-

TI-A10

7 Pages

-

TI-P30

1 Pages

-

Dimensions, type KRG

1 Pages

-

Dimensions, type KRP/T

1 Pages

-

Dimensions, type KRP

1 Pages

-

Dimensions, type KR, K

2 Pages

-

SITEMA Safety Catchers

2 Pages

-

SITEMA Locking Units KFH

6 Pages

-

STB10 Rod Attachment STB

3 Pages

-

SITEMA Applications

2 Pages

-

F60 Dimensions, type KFHA

6 Pages

-

Z10 - Auto Bleeder

3 Pages

-

SITEMA Safety Locks KRG

1 Pages

-

SITEMA company

15 Pages

-

Locking Units KFPC

3 Pages

-

Locking units series KFPA

4 Pages