Catalog excerpts

360 PLASTIC CONTAINER MANUFACTURING EXPERTISE 360а PLASTIC CONTAINER MANUFACTURING EXPERTISE >

Open the catalog to page 1

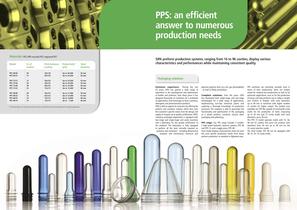

Up p to 2 1, 600 Up p to 1 4,4 00 Up p to 10 , 800 Up p to 7, 200 > * The above figures are indicative and they must be confirmed by the Technical Department for specific applications. size="-1">

Open the catalog to page 2

3 4 4 1 1 3 2 2 > 1 Plastification. Previously dehumidified PET granules are plasticized in the extruder using a screw specifically designed by SIPA. During the plastification stage the material is melted, homogenized and slowly transported by the screw in order not to generate shear stress and consequently produce AA. 2 Preform injection. The melted material is injected into the mold by means of an optimized injection profile aimed at obtaining high quality preforms. 3 Preform cooling. Once the injection cycle has been completed, the preforms are picked up by an integrated transport...

Open the catalog to page 3

Greatrangeofpreforms High quality and clean preforms Optimizedcycletimes Limited consumption and costs The heart of the system: the injection mold > SIPAs PPS range of machines was first developed and then expanded to offer a simple product capable of addressing the needs of any specific project. The various models in the range allow the production of different types of preforms while guaranteeing constant quality and high savings. SIPA prides itself of a broad experience both in the design of containers as well as preforms. This experience makes it possible to satisfy the client from the...

Open the catalog to page 4

The extruder continuously plasticizes PET with a specially designed screw eliminating any back-flow of melted material. Thanks to the continuous extrusion, the average melting speed is decreased and results in a lower stress on the material and reduced production of AA. Օ Layered injection mold structure (Adaptor plate - base plate - hot runner - nozzle plate - cavity plate - cores plate). Two-way elevator integrated in the machine. Third independent elevator for non-compliant performs. Օ Enhanced temperature control of molds (4 different cooling circuits). Preforms unload from cooling belt...

Open the catalog to page 5

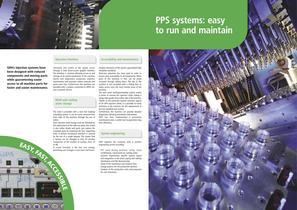

Operator interface Accessibility and maintenance SIPAs injection systems have been designed with reduced components and moving parts while guaranteeing easier access to all machine parts for faster and easier maintenance. > Command and control of the system occurs through a color touch-screen graphic interface. The interface is intuitive allowing access to and storage of all control parameters of the machine, alarms and diagnostics, production statistics, maintenance and operation videos, manuals and spare parts lists. Furthermore, the machines are provided with a modem connection to SIPAҒs...

Open the catalog to page 6

SIPA INDIA B 101, Mangalya Off Marol Maroshi Road Marol, Andheri (East) Mumbai - INDIA 400 059 Tel: ++91 22 29201785 Fax: ++91 22 29201795 E-mail: sipa.india@zoppas.com SIPA MACHINERY HANGZHOU SIPA THAILAND # 3 Road 14, Economic & Technology Development Zone 310018 Hang Zhou, Zhejiang province - CHINA Tel: ++86 571 86913106 Fax: ++86 571 86913548 Bangna Complex 947/150 4th Floor, Moo 12 Bangna - Trad Road, Bangna Bangkok 10260 - THAILAND Tel: ++66 27695451 Fax: ++66 27695452 E-mail: sipa.fareast@zoppas.com SIPA CHINA Room 1408, Scitech Tower 22 Jianguomenwai Avenue Beijing 100 004 - CHINA...

Open the catalog to page 7All SIPA catalogs and technical brochures

-

XFORM 500 Preform System

8 Pages

-

SFL Linear Blowing Systems

8 Pages

-

ECS Integrated Systems

6 Pages

-

Cartoning solutions

6 Pages

-

C09 r1 09 pal depal

9 Pages

-

C14 SIPA Magazine issue6 2014

72 Pages

-

Start Blow

2 Pages

-

SFR Rotary Blowmolders

12 Pages

-

SFL Linear Blowmolders

6 Pages

-

Pallettising/Depallettising

16 Pages

-

Process

7 Pages

-

Sincro TriBloc

9 Pages

Archived catalogs

-

Filling technology_2013

9 Pages

-

Filling technology_2009

16 Pages

-

SincroBloc

7 Pages

-

ECS Integrated Systems

12 Pages

-

SIPA Complete lines

4 Pages

-

SIPA Product Range

8 Pages