Catalog excerpts

3 6 0 ° F R O M P E L L E T T O P A L L E T E X P E R T I Z E SINCRO BLOC Integrated Blowing / Filling / Capping System

Open the catalog to page 1

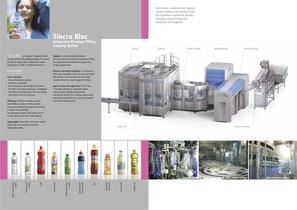

Sincro Bloc combines the highest output today in the market with the maximum container quality keeping reduced footprint, simplicity and hygiene. Sincro Bloc Integrated Blowing / Filling Capping System Filling Sincro Bloc is a compact integrated system for high speed blowing/lling/capping. The system guarantees high quality standard and output ranging from 14,000 to 52,800 bottles/hour. Advantages Costs reduction: - Reduced operators number. - Reduced consumption. - No air conveyors: less energy consumption. - No rinser: less water and energy consumption. - Elimination of maintenance costs...

Open the catalog to page 2

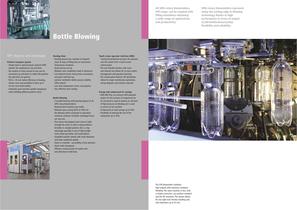

All SIPA rotary blowmolders, SFR range, can be coupled with filling monoblocs obtaining a wide range of applications and productivity. Bottle Blowing SFR: features and advantages Preform transport system - Simple chain in special plastic material (SIPA patent). No maintenance cost and time. - No rotation of chain around its axis and no movement up and down to collect the preform. - Dry operation (no grease). - Pitch = 45 mm: better efciency of heating, shorter oven and possibility to blow up to 43 mm neck nish bottles. - Extremely quick tool-free spindle changeover when handling different...

Open the catalog to page 3

“Lightweight” bottles Sincro Bloc, thanks to its direct connection between bottle blowing and filling, is the perfect solution in case of lightweighting necks and bottles. Connection between filler and blow molding machine Transfer module Optional elements Bottles are easily transferred from the blowing machine by means of a special “exible” gripper rst star-wheel to avoid bottles jam: the starwheel was designed with exible pockets, which adjust any misalignment in the release of the blown bottles. Again in this area, the bottle release is controlled in the event of a ller stop. The...

Open the catalog to page 4

Filling Here is a list of the ller model which can be used in the Sincro Bloc solution with relative valve section: STILLFILL S P Stillfill S P Gravity ller for still water. Volumetric gravity ller for sensitive non-carbonated products. The lling/capping area, whatever the type of ller used, it is congured with laminar ow cabins. Depending on the level of hygiene required by the customer, the hygiene level can reach ISO class 5. Unitronic P Mechanical isobaric ller for carbonated products. Volumetric isobaric ller for carbonated products. Isotronic P Gravity ller with recirculation for hot...

Open the catalog to page 5

Capping machine The last element in the process is the capping machine, which, synchronized with the ller, closes the bottles prior to outfeed. The management and correct feed of caps in the pick and place area is one of the most sensitive phases in the whole process in terms of risk of blockage on the descent channel. Since the whole process is fully synchronized we have designed several solutions to avoid stoppages on the Sincro Bloc caused by cap feed problems. In the event of a cap blockage, a signal blocks the preform feed and a special buffer empties the whole system without wasting...

Open the catalog to page 6

SINCRO BLOC SIPA FILLING & PACKAGING DIVISION Via Provinciale, 36 43038 Sala Baganza (PR) ITALY Tel. +39 0521 548111 Fax +39 0521 548112 E-mail: sipaberchi@zoppas.com Website: www.sipa.it SIPA RUSSIA Ul. Ordzhonikidze, 11 Str. 1/2 115419 Moscow - RUSSIA Tel: +7 495 2324191 Fax: +7 495 2324190 E-mail: sipa_russia@co.ru SIPA UKRAINE Office 37, 9 Turovs’ka St., Kyiv 254655 Kiev - UKRAINE Tel: +38 044 4636817 Fax: +38 044 4257275 E-mail: sipa.ukraine@zoppas.com SIPA ENGINEERING S.r.l. Str. Mangalia, 61 300186 Timisoara - ROMANIA Tel: +40 356 434200 Fax: +40 356 434280 E-mail:...

Open the catalog to page 7All SIPA catalogs and technical brochures

-

XFORM 500 Preform System

8 Pages

-

SFL Linear Blowing Systems

8 Pages

-

ECS Integrated Systems

6 Pages

-

Cartoning solutions

6 Pages

-

C09 r1 09 pal depal

9 Pages

-

C14 SIPA Magazine issue6 2014

72 Pages

-

Start Blow

2 Pages

-

SFR Rotary Blowmolders

12 Pages

-

SFL Linear Blowmolders

6 Pages

-

Pallettising/Depallettising

16 Pages

-

Process

7 Pages

-

Sincro TriBloc

9 Pages

Archived catalogs

-

Filling technology_2013

9 Pages

-

Filling technology_2009

16 Pages

-

ECS Integrated Systems

12 Pages

-

SIPA Complete lines

4 Pages

-

SIPA Product Range

8 Pages

-

SIPA PPS Preform Production

7 Pages