Catalog excerpts

e x pert i z e P A L L E T T O P E L L E T F R O M 3 6 0 ° SINCRO TRIBLOC Integrated solution for blowing, labelling, filling and capping

Open the catalog to page 1

Sincro TriBloc Integrated solution for blowing, labelling, filling and capping Bottle blowing Preform heating Hygiene: a preform treatment system, the direct connection between blowing, labelling and filling, the over-pressured environment are guaranty of high hygiene level. Extreme operating flexibility: it can handle a wide range of bottles, necks and caps sizes (both flat and sport). Several technical innovations installed allow for a short change-over times. Bottle exit Preform feeding Hot filled products Isotonic and sport drinks Tea Clear juice Bottle blowing Costs reduction: -...

Open the catalog to page 2

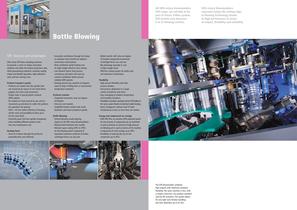

All SIPA rotary blowmoulders SFR range, are suitable to be part of Sincro TriBloc system. SFR models vary between 6 to 27 blowing cavities. Bottle Blowing SFR: features and advantages SIPA rotary SFR blow moulding machines incorporate a series of unique innovative solutions and allow the fastest production rates while guaranteeing optimum container quality, simple and flexible operation, high utilization rates and low running costs. Preform transport system - Preforms are loaded onto the spindle (and not viceversa) by means of cam track-driven grippers. No chain axial movement. - Simple...

Open the catalog to page 3

“Lightweight” bottles Sincro TriBloc, thanks to its direct connection between bottle blowing, labelling and filling, is the perfect solution in case of lightweight necks and bottles. Connection between blowmoulder, labeller and filling/capping machine Transfer module The blowmoulder, labeller and filler are electronically synchronized and physically connected by transfer modules. The latters are composed of transfer starwheels which transport the bottles by the neck to the labelling machine and then to the filling monoblock. This solution offers the following main advantages: - Extreme...

Open the catalog to page 4

One cylinder only for label cutting and dispensing - no more critical passage between cutting and dispensing as is the case with classical Roll-Fed labellers. Bottle labelling ADHESLEEVE technology, a real revolution in the field of Roll-Fed labelling! Adhesleeve is a labelling machine which uses preglued transparent or white Roll-Fed film with thicknesses lower than the films that are normally used on classic Roll-Fed labellers with less weight as a result. It is an eco-friendly solution: the absence of hot melt makes the label free from any contamination, so 100% recyclable, together with...

Open the catalog to page 5

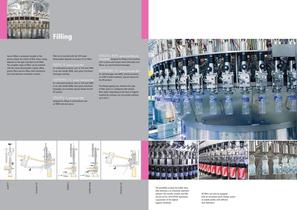

Filling Filler to be matched with the SFR rotary blowmoulder depends on product to be filled: ISOFILL P, isobaric level filler: for carbonated products such as CSD and CMW, it can also handle SMW, clear juices, functional beverages and beer. ISOTRONIC SC, isobaric volumetric filler: for carbonated products such as CSD and CMW, it can also handle SMW, clear juices, functional beverages, tea and beer. Special release for hot fill product. STILLFILL S, Stillfill R\HR Stillfill S Isotronic SC Isofill P gravity level filler: designed for filling of cold products such as SMW and clear juices....

Open the catalog to page 6

Capping machine The last element in the process is the capping machine, which, synchronized with the filler, closes the bottles prior to outfeed. The management and correct feed of caps in the pick and place area is one of the most sensitive phases in the whole process in terms of risk of blockage on the descent channel. Since the whole process is fully synchronized we have designed several solutions to avoid stoppages on the Sincro TriBloc caused by cap feed problems. In the event of a cap blockage, a signal blocks the preform feed and a special buffer empties the whole system without...

Open the catalog to page 7

Sincro TriBloc Efficency and flexibility High efficiency Great flexibility Quick changeovers Sincro TriBloc guarantees high efficiency rate of the single machines but above all of the whole system. However, every single unit in the Sincro TriBloc system can be decoupled from the bloc so that bottles and/or preforms can be evacuated if there is a micro-stop in the system, whether it be in the blowing station, the labelling station or the filling and capping station. Sincro TriBloc offers the unique advantage of filling mineral water, carbonated soft drinks and juices in hot fill in the same...

Open the catalog to page 8

SINCRO TRIBLOC SIPA Filling & Packaging Division Via Provinciale, 36 43038 Sala Baganza (PR) ITALY Tel: +39 0521 548111 Fax: +39 0521 548112 E-mail: sipaberchi@zoppas.com Website: www.sipa.it SIPA RUSSIA Ul. Ordzhonikidze, 11 Str. 1/2 115419 Moscow - RUSSIA Tel: +7 495 2324191 Fax: +7 495 2324190 E-mail: sipa_russia@co.ru SIPA UKRAINE Office 37, 9 Turovs’ka St., Kyiv 254655 Kiev - UKRAINE Tel: +38 044 4636817 Fax: +38 044 4257275 E-mail: sipa.ukraine@zoppas.com SIPA ENGINEERING S.r.l. Str. Mangalia, 61 300186 Timisoara - ROMANIA Tel: +40 356 434200 Fax: +40 356 434280 E-mail:...

Open the catalog to page 9All SIPA catalogs and technical brochures

-

XFORM 500 Preform System

8 Pages

-

SFL Linear Blowing Systems

8 Pages

-

ECS Integrated Systems

6 Pages

-

Cartoning solutions

6 Pages

-

C09 r1 09 pal depal

9 Pages

-

C14 SIPA Magazine issue6 2014

72 Pages

-

Start Blow

2 Pages

-

SFR Rotary Blowmolders

12 Pages

-

SFL Linear Blowmolders

6 Pages

-

Pallettising/Depallettising

16 Pages

-

Process

7 Pages

Archived catalogs

-

Filling technology_2013

9 Pages

-

Filling technology_2009

16 Pages

-

SincroBloc

7 Pages

-

ECS Integrated Systems

12 Pages

-

SIPA Complete lines

4 Pages

-

SIPA Product Range

8 Pages

-

SIPA PPS Preform Production

7 Pages