Catalog excerpts

AFChina, founded in 2011, is dedicated to manufacture high quality aramid fibers. With our own independent intellectualproperty rights, We specialized in high-strength and highmoduluspara-aramid from 100 to 15000 Denier which are widely used in hoses, optical cable, tyre cords and bulletproof. In 2022, AFChina is able to manufacture over 5000 tons/year of para-aramid annually and is expected to expand capacity to 7000 tons/year in the future. To serve our customers better, we also process selfmade filaments to staple fiber, short-cut fiber and pulp, ensuring quality and exploring application field with our powerful R&D team. With faith in this industry and technology, AFChina aims to be the largest para-aramid manufacturer in China and your most reliable supplier around the world. Succeed by profession, win by quality is our faith. AFChina passed ISO9001, IATF16949 quality management system, ISO14000 environment protection system, OHSAS18001 Occupation Health Safety Management System, aiming to be a modern high-tech company by scientific management. Since the breakthrough of our highstrengthand high-modulus paraaramid,AFChina has been rewarded by Shandong government and Technology bureau as provincial key high-tech and innovation enterprise.

Open the catalog to page 1

Began basic R&D of Para-Aramid in Tsinghua Univesity AFChina and Tsinghua Univesity launched joint development project for commercialization.Brand name of "VICWA" Development of Para-Aramid pilot technology completed. Established annual production capacity up to 1000T. Established annual production capacity up to 5000T

Open the catalog to page 2

“VICWA®”is a trademark of aramid fiber manufactured by AFChina Corporation. Aramid is short for "aromatic amide". It refers to the reinforced fiber in light weight with the tensile strength five times stronger than the iron of same weight with high heat resistance and low cutability. Due to its characteristics, it presents high value for use in industries in request of high strength, flame resistance and light weight. “VICWA®”Processed fiber products, such as staple fiber, short-cut fiber, pulp, paper,honeycomb are also available. High strength-to-weight ratio Heat and chemical resistance...

Open the catalog to page 3

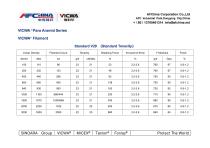

Linear Density Filament Count Breaking Force Elongationat Break

Open the catalog to page 4

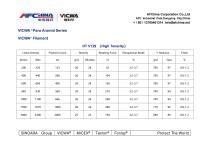

Linear Density Filament Count Breaking Force Elongationat Break

Open the catalog to page 5

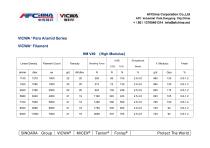

Linear Density Filament Count Breaking Force

Open the catalog to page 6

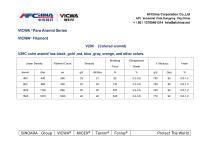

Linear Density Filament Count

Open the catalog to page 7

Linear Density Filament Count Elongationat Break VICWA® para-aramid filament yarn should be kept dry in original bags and properly stocked. Preferably store at room temperature with 35-65% relative humidity.Avoid the sun, rain and fire. 1. Each bobbin packed in black plastic film bag.Net weight: 5.00kg 2. 23 bobbins per layer and 3layers per carton. Carton size: 110*110*95cm Net weight: 345.00kg,Gross weight: 445.00kg 3.Shipment by sea: Generally 20 pallets can be loaded into 20 feet container with total net weight of 6,900kg.

Open the catalog to page 8

Para-aramid pulp is made from Vicwa filament yarn whose composition is poly(para-phenylene terephthalamide). After a series process of cutting, grinding and suspending in water, the fiber is fibrillated into pulp. The pulp not only inherits the high-strength,high-modulus, high-temperature resistance, abrasion resistance and excellent chemical stability from para-aramid fiber, but also has high dispersibility, specific surface area and grip force to provide reinforcement and viscosity control under shear stress. C.S.F Surface Area Moisture Content Avarange Fiber Length

Open the catalog to page 9