Website:

SIM Automation GmbH

Website:

SIM Automation GmbH

Catalog excerpts

Belt bunkersFilling weight up to max. 5kg / 35kg Specifications may change as design revisions take place. Revision: 1.0 2019-06-05 SIM Automation GmbH Liesebuhl 20 D-37308 Heilbad Heiligenstadt, Germany Telephone: +49 (0)3606 / 690-474 Facsimile: +49 (0)3606 / 690-335 e-mail: info@sim-automation.de Internet: www.sim-automation.de

Open the catalog to page 1

Filling weight up to max. 5kg/35kgContents Page 1. Belt bunkers - general 3 2. Belt bunkers up to maximum 5kg (B series) 4 3. Belt bunkers up to maximum 35kg (C series) 5 4. Belt bunker accessories 6 4.1. Filling level monitor 4.2. Level control type BSN 4.6. Installation of another belt 5. Belt bunkers and accessories - Price list Specifications may change as design revisions take place. Revision: 1.1 2019-06-05 SIM Automation GmbH Liesebuhl 20 D-37308 Heilbad Heiligenstadt, Germany Telephone: +49 (0)3606 / 690-474 Facsimile: +49 (0)3606 / 690-335 e-mail: info@sim-automation.de Internet:...

Open the catalog to page 2

Belt bunkers Filling weight up to maximum 5kg/35kg 1. Belt bunkers - general Description: The core of the belt bunker is a conveyor belt/transport belt on which parts move onto a sloped chute. To obtain a certain level of fill, a hopper is mounted on the belt. The transport belt is powered by a gear motor. The belt bunkers can be adapted individually irrespective of the parts they transport. Extensive accessory items adapt the belt bunker to different tasks. Belt bunkers of different volumes and filling weights are available: Besides, customized modifications/changes can be made to these...

Open the catalog to page 3

Belt bunkersFilling weight up to maximum 5kg/35kg2. Belt bunkers up to maximum 5kg (B series) Technical specifications Max. filling weight: Belt speed: Belt: Belt tension: Bunker hopper: Outlet curtain: Chute: AC gear motor: Lid: Surfaces: 3-meter connecting cable Other versions and data on request 5 kg 0.1 m /min white, FDA-approved black, not FDA-approved set at tensioning screws outside Stainless steel Vulkollan Stainless steel brushed, slope can be set (max. 45° IP50 230V/50Hz and 115V/60Hz Power consumption 5 W Polycarbonate, non-hinged Drive guard RAL5021 Base plate with grid pattern...

Open the catalog to page 4

Belt bunkersFilling weight up to maximum 5kg/35kg3. Belt bunkers up to maximum 35kg (C series) Technical specifications: Max. filling weight: Belt speeds : Belt: Belt tension: Bunker hopper: Outlet curtain: Chute: motor: 35 kg 0,1 m /min (24V / 230V) or 0,6 m /min (230V) white, FDA-approved black, not FDA-approved set at tensioning screws outside Stainless steel Vulkollan Stainless steel brushed, slope can be set (max. 45°) AC gear motor 230V/50Hz (standard configuration) or 115V/60Hz - Power consumption 7,2 W DC gear motor 24V (only for BB-05-C and BB-10-C) - Power consumption 4,3 W IP50...

Open the catalog to page 5

Belt bunkersAccessories - level monitors4. Belt bunker accessories 4.1. Filling level monitor Filling level monitor in general Filling level monitors reporting part levels in the belt bunker or the hopper are available. Level monitors for belt bunkers in general The purpose of the level monitor is to warn the operator to replenish the stock of parts. The information can be generated in two different ways. - Optically by one-way light barrier - Reflection by ultrasonic sensor Both systems are contactless. The type of level monitor depends on the case on hand and the type of parts detected....

Open the catalog to page 6

Belt bunkersAccessories - level monitors Belt bunker level monitoring from top In this case, an ultrasonic sensor is used. - The type depends on the material, the surface finish and the shape of the parts detected - Works from top - Operates without contact Designation: ZFSKB-Ultra Specifications may change as design revisions take place. Revision: 1.1 2019-06-05 SIM Automation GmbH Liesebuhl 20 D-37308 Heilbad Heiligenstadt, Germany Telephone: +49 (0)3606 / 690-474 Facsimile: +49 (0)3606 / 690-335 e-mail: info@sim-automation.de Internet: www.sim-automation.de

Open the catalog to page 7

Belt bunkers Accessories - level monitors Level monitoring for bowl feeder in general The purpose of the level monitor in the bowl feeder is to maintain the optimum or minimum level of parts in the vibration helical or other feeder. The signal controls the automatic replenishment of parts or warns the operator to add parts. The information can be generated in two different ways. - Electro-mechanically by pendulum - Reflection by ultrasonic sensor The first version requires physical contact whereas the other version works without contact, that is the parts are not exposed to stress. The type...

Open the catalog to page 8

Belt bunkersAccessories - level monitors Level monitoring in bowel feeder by ultrasonic sensor - Level scanned in the feeder bowl by ultrasonic sensor - Operates without contact - The size of the boom can be customized - Detection range: 25 - 400mm - Cross member of hinged design Length: L1 standard 300 mm L2 standard 400 mm Other lengths on request Specifications may change as design revisions take place. Revision: 1.1 2019-06-05 SIM Automation GmbH Liesebuhl 20 D-37308 Heilbad Heiligenstadt, Germany Telephone: +49 (0)3606 / 690-474 Facsimile: +49 (0)3606 / 690-335 e-mail:...

Open the catalog to page 9

Belt bunkersAccessories - level control4.2. Level control type BSN Level controls in general The level controls turn the belt bunker on or off as a function of the level of the downstream components they monitor. The level is controlled by the sensor at a defined position. The sensor output voltage is 0V when parts are present. The belt bunker is turned off. If the level drops below minimum, the sensor output voltage switches to 24V. Now +24V is available at the sensor output and the voltage supply to the belt bunker is switched on after approximately 2-3 seconds. The belt bunker is turned...

Open the catalog to page 10

Belt bunkersAccessories - Level control / dosing baffle 4.3. Dosing baffle The dosing baffle restricts the outlet aperture of the belt bunker and keeps it at a defined size. This is helpful particularly with heavy parts which cannot sufficiently be withheld by the curtain. When ordered as a complete unit, the dosing baffle is installed mechanically in the belt bunker. If you want to service fit the dosing baffle, the bottom horizontal bar must be shifted; this means you have to drill 2 holes in the side walls. To make installation simple, punch-marks are provided where the holes for the...

Open the catalog to page 11All SIM Automation GmbH catalogs and technical brochures

-

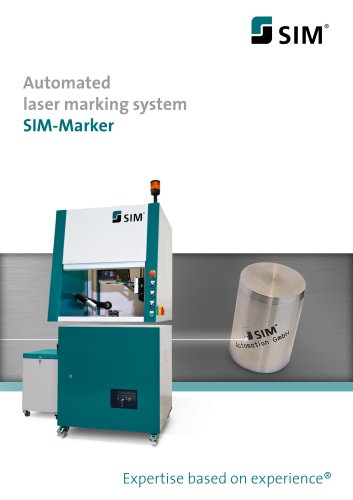

SIM-Marker

4 Pages

-

SIM belts Brochure en

28 Pages

-

SIM-Marker

4 Pages

-

SIM-Marker

4 Pages

-

SIM-Marker Mini

4 Pages

-

SIM-Marker Classic

4 Pages

-

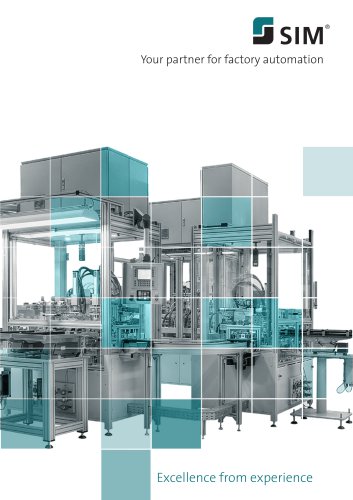

SIM Imageflyer

6 Pages

-

SIM Imageflyer

6 Pages

-

SIM Imageflyer

6 Pages

-

SIM Mini

4 Pages

-

SIM Classic

4 Pages

-

SIM Imageflyer

6 Pages

-

SIM Imageflyer

6 Pages

-

SIM Imageflyer

6 Pages

-

SIM Imageflyer

6 Pages

-

SIM Imageflyer

6 Pages

-

company presentation

18 Pages