Catalog excerpts

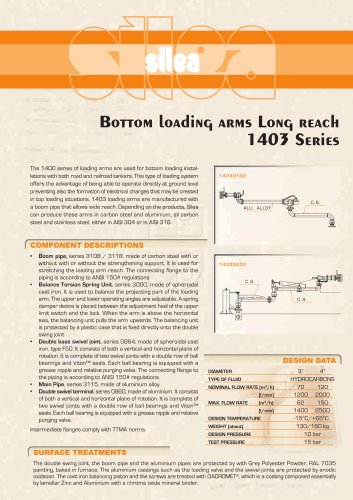

BOTTOM LoAdiniq ARMS LoNq REACII The 1400 series of loeding arms are used for bottom loading instal- lations with both roed and railroad tankers. This type of loading system offers the advantage aí being able to operate directly at ground level preventing also the formation of electrical charges that may be created in top loading situations. 1403 loading arms are manufactured with a boom pipe that allows wide reach. Depending on the products, Silea can produce these arms in carbon steel and aluminium, all carbon steel and stainless steel, either in AISI 304 or in AO 316. ■ Boom pipe, series 3108 / 3118, made of carbon steel with or without with or without the strengthening support. It is used for stretching the loading arm reach. The connecting flange to the piping is according to ANSI 150# regulations ■ Balance Torsion Spring Unit, series 3000. made of spheroidal cast iron. It is used to balance the projecting part of the loeding arm. The upper and lower operating angles are adjustable. A spring damper device is placed between the adjustment heel of the upper limit switch and the lock. When axis, the balancing unit pulls the swing joint ■ Double base swivel joint, series 0864, made ot spheroidal cast iron, type F50. It consists of both a vertical and horizonte! plane of rotation. It is complete of two swivel joints with a double row of ball bearings and Viton™ seals. Each ball bearing is equipped with a grease nipple and relative purging valve. The connecting flange to the piping is according to ANSI 15D# regulations. ■ Main Pipe, series 3115. made of aluminium alloy. ■ Double swivel terminal, series 0860, made of a..imir' i.m. it consiste of both a vertical and horizontal plant two swivel joints with a double row seals. Each ball bearing is equipped wit purging valve. itermediate flanges comply with TTMA [ SURFACE TREATMENTS NOMINAL FLOW RATE (m3/!!) □EBIGN TEMPERATURE WEIGHT [about) DESIGN PRESSURE The double swing joint, the boom pipe and the aluminium pipes are painting, baked in furnace. The aluminium castings such as the loadi oxidation. The cast iron balancing piston and the screws are treated wit by lamellar Zinc and Aluminium with a chrome oxide mineral binder. :h Grey Polyester Powder, RAL 7035 swivel joints are protected by anodic vhich is a coating composed essentially

Open the catalog to page 1

For standard lengths and working range, please refer to the drawings on the following pages. Silea arm dimensions and material can be modified according Each 1403 loading arm is identified by its serial number • Declaration of material conformities and functional test • Complete loading ¡«TU riiiiiiit.K'iiiiice kit code. following alternatives ' e swivel joints series NFT879. They ai Piston balancing unit, series 2030. made of a thick external tubular casing in carbon steel, internal sliding rod in stainless steel with terminal spherical joint and some internal compression springs for...

Open the catalog to page 2

Long reach battom laading/ un loa ding arm Arm dimensions and materials can be modified according to Customer requirements

Open the catalog to page 3

1403_ing 2-03-2007 17:45 Pagina 4 C Colori compositi M Y CM MY CY CMY K

Open the catalog to page 4All Silea liquid transfer srl catalogs and technical brochures

-

1052 series

4 Pages

-

ELECTROPUMP GROUP

7 Pages

-

MOTOR PUMP

2 Pages

Archived catalogs

-

Tank-Truck equipements

28 Pages

-

TANK'TRUKS EQUIPEMENTS CATALOGUE

28 Pages