Catalog excerpts

Product Data Sheet Version 02 / 2011 SikaBlock® M700 Areas of Application Product Benefits Manufacture of data control models and cubings Manufacture of master models Manufacture of moulds for low pressure reaction injection moulding Vacuum forming moulds for lower number of pieces Very high dimensional stability High compressive strength and edge stability Good solvent resistance High heat distortion temperature Easy machinability Low dust formation when milled Very dense, fine surface Easy to seal and good to varnish Basis Adhesive Filler Polyurethane, light brown Biresin ® Kleber braun, two-component-PUR-system, brown Biresin ® Spachtel braun, two-component-polyester-system, brown Physical Data (approx.-values) SikaBlock® M700 Density Shore hardness Flexural strength Compressive strength Impact resistance Heat distortion temperature Linear thermal expansion coefficient αT Processing Data Biresin ® Kleber braun Adhesive / Filler Mixing ratio Biresin ® Spachtel braun Setting time Biresin® Kleber braun, resin Biresin® G53, hardener Biresin® Spachtel braun, resin BPO-Paste, hardener 1500 mm x 500 mm x 30 mm, 30 pieces / pallet 1500 mm x 500 mm x 50 mm, 25 pieces / pallet 1500 mm x 500 mm x 75 mm, 16 pieces / pallet 1500 mm x 500 mm x 100 mm, 12 pieces / pallet 1500 mm x 500 mm x 150 mm, 8 pieces / pallet 1.5 kg net 4 kg; 0.975 kg net 2 x 8.74 kg net cartridges 6 x 1.76 kg net tins in a box 2 x 0.16 kg net sticks (for cartridges) 6 x 0.04 kg net tubes in a box (for tins) 1/2 Board materials Tooling & Composites Model board

Open the catalog to page 1

The material must be acclimatised to 18 - 25°C prior to machining. Machining of the block is easily accomplished by sawing, milling and so on with high performance tools or by hand. Bonding areas must be clean, dry and free of dust and grease or oil. For bondings use e. g. Biresin® Kleber braun (for more information see Technical Data Sheet). For more information about milling please seek advice from cutting tool manufacturer or our separate leaflet. For correction or finishing of surface use Biresin ® Spachtel braun (for more information see Technical Data Sheet). Product has un-limited...

Open the catalog to page 2All Sika Deutschland catalogs and technical brochures

-

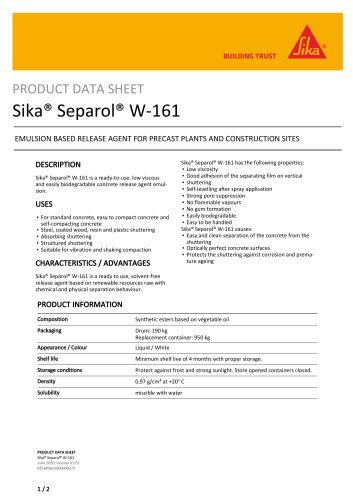

Sika® Separol® W-161

2 Pages

-

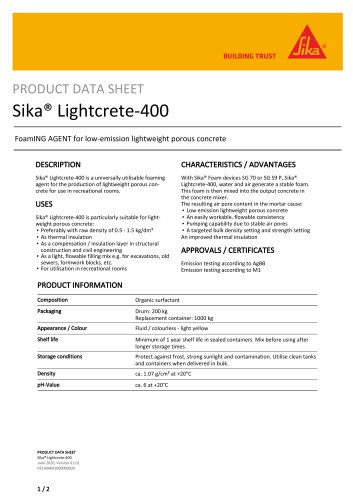

Sika® Lightcrete-400

2 Pages

-

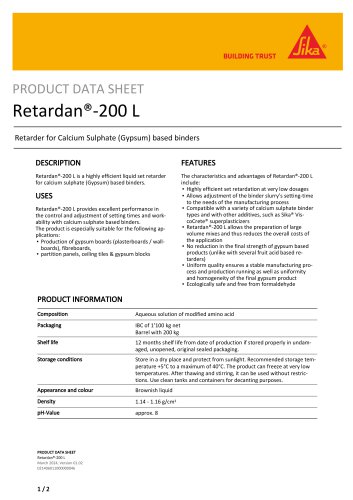

Retardan®-200 L

2 Pages

-

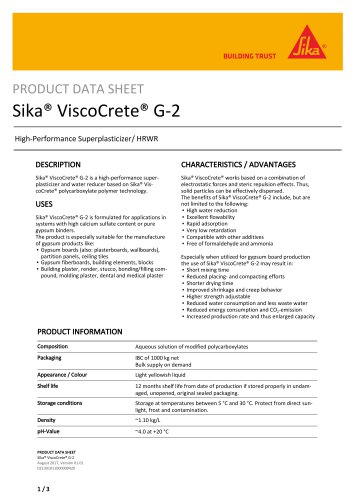

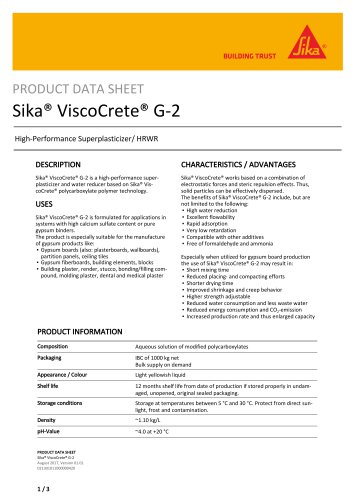

Sika® ViscoCrete® G-2

3 Pages

-

Sika® ViscoCrete® G-2

3 Pages

Archived catalogs

-

SIKA GYPSUM ADDITIVES

12 Pages

-

PNEUMATIC GUNS

2 Pages

-

SikaRapid®-800 P

2 Pages

-

Sika® PowerPack-10 MF

2 Pages

-

retardan-l

2 Pages

-

Sika® Lightcrete-400

2 Pages

-

Sika® ViscoCrete® G-2

3 Pages

-

additive

4 Pages

-

ADHESIVES STRUCTURAL BONDING

8 Pages

-

LOW PRESSURE RIM-SYSTEMS

4 Pages

-

CR170

3 Pages

-

Biresin® CR120

6 Pages

-

CR80

6 Pages

-

Biresin® LS

2 Pages

-

M72

2 Pages

-

Biresin® M67

2 Pages

-

Biresin® S15

2 Pages

-

Biresin® G26

2 Pages

-

Sika® Release LG

2 Pages

-

M75

2 Pages

-

VG70

2 Pages

-

u1419

2 Pages

-

M150

2 Pages

-

M330

2 Pages

-

M440

2 Pages

-

M450

2 Pages

-

M650

2 Pages

-

M73

3 Pages

-

M1000g

2 Pages

-

Milling Parameters

9 Pages

-

Imagebrochure

8 Pages

-

SikaBlock Board Materials

3 Pages

-

Composite Systèmes

3 Pages

-

Overview Brochure

15 Pages

-

Low Pressure RIM Systems

2 Pages

-

Biresin® L89

2 Pages

-

Biresin® S5

2 Pages

-

Biresin® RG53 Fibre

2 Pages

-

Biresin® RG51 HS

2 Pages

-

Biresin® RG50

2 Pages

-

Biresin® U1419

2 Pages

-

Biresin® VG70

2 Pages

-

Biresin® M60

2 Pages

-

Biresin® M72

2 Pages

-

SikaBlock® M150

2 Pages

-

Biresin CR

2 Pages

-

Ideas take shape

14 Pages

-

Brochure English / German

9 Pages