Catalog excerpts

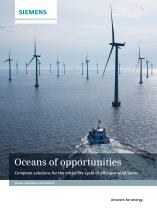

Oceans of opportunities Complete solutions for the entire life cycle of offshore wind farms www.siemens.com/wind

Open the catalog to page 1

Sustainable profit Offshore wind power – firmly established as a viable source of renewable energy

Open the catalog to page 2

Due to higher, more consistent wind speeds at sea, offshore wind turbines can generate substantially more energy than onshore wind turbines. Offshore wind farms may reach capacity factors in the range of 50%. Even considering the planning constraints relating to shipping lanes, fishing, bird migration, and the like, the world has abundant space for offshore projects. When it comes to offshore wind power, no supplier can match Siemens in terms of experience and reliability. Siemens has a proven track record for delivering offshore projects on budget. From the world’s first offshore wind farm...

Open the catalog to page 3

Siemens offers integrated solutions and services that perfectly meet the high demands along the entire wind energy conversion chain Number one in offshore Grown from experience Siemens has developed a broad realm of experience and excellent skills in delivering offshore projects. From the outset Siemens has played a key role in founding the offshore wind industry by installing the world’s first offshore wind farm in Vindeby, Denmark, in 1991. The 11 turbines installed in this pioneering project are still in excellent condition. The turbines have consistently operated at high availability,...

Open the catalog to page 4

Siemens can also supply turnkey grid connections for wind farms, including construction of the offshore transformer station Delivering on a promise Delivering projects on time and within budget is one of Siemens’ major strengths. Since the offshore industry was established in 1991, and despite the logistical challenges associated with offshore installation works, every Siemens offshore project has been completed within budget and on time. This unique track record was not established by chance. It requires deep respect for the challenging conditions, detailed planning, and superior and...

Open the catalog to page 5

Maximized potential across the board A well-proven and robust installation process Components delivery to port Siemens transports all components, parts and equipment to a harbor site close to the proposed wind farm. The site serves as the assembly and embarkation station for the project. Pre-assembly of components Once all necessary compon ents have been delivered, pre assembly commences. Siemens designs, plans, and executes all work processes to minimize the amount of work required offshore. Storage of rotor blades Specialists place rotor blades in the storage area, ready for shipment...

Open the catalog to page 6

Experience counts in installation Drawing on more than two decades of experience in successfully delivering offshore projects on time and within budget, Siemens knows exactly what it takes. Over the years, a large number of aspects of installation methodology have been tested and analyzed. Gradually, best practices have been established, and even though the process often needs to be adjusted to fit project- specific re uirements, the fundamental approach remains q the same. By thoroughly understanding the complexity and challenges associated with implementing an offshore project, and by...

Open the catalog to page 7

Blades on a service vessel before mounting Simply the best The fundamental pillars – the best turbines and the best service Turbine types offered Two Siemens turbine types are offered for offshore projects, the SWT-2.3 and the SWT-3.6. Both types offer the same key features. Rotor The rotor blades for Siemens’ offshore turbines are made of fiberglass-reinforced epoxy, manufactured using the proprietary Siemens IntegralBlade® process. Unlike conventional wind turbine blades, the IntegralBlades® are cast in one piece in a closed process. This p rocess leaves no weak points at glue joints...

Open the catalog to page 8

Blades being transported before mounting Grid performance Grid stability requirements grow as more wind power is fed into the grid. Siemens also sets the standard in the field of grid compliance. Power conversion is implemented with Siemens’ unique NetConverter® system. This system uses full conversion of the power generated, efficiently decoupling generator and turbine dynamics from the grid. The NetConverter® system offers maximum flexibility in the turbine response to voltage and frequency control, fault ride-through, and output adustment. As a result, Siemens urbines comply j t with...

Open the catalog to page 9

Offshore projects and references More than 20 years of experience and over two gigawatts of installed capacity Vindeby, Denmark 1991 Location: Rated capacity: Scope of supply: Distance to shore: Water depth: Operator: Baltic Sea 4.95 MW 11 x 450 KW 1.5 km 1–5 m DONG Energy Location: Rated capacity: Scope of supply: Distance to shore: Water depth: Operator: Location: Rated capacity: Scope of supply: Distance to shore: Water depth: Operator: Öresund, Baltic Sea 40 MW 20 x 2.0 MW 3.5 km 2–6 m DONG Energy, Middelgrundens Vindmøllelaug Baltic Sea 23 MW 10 x SWT-2.3-82 3.5 km 20 m Samsø Havvind A/S

Open the catalog to page 10

World’s first offshore wind farm Siemens was the first wind turbine manufacturer to venture out to sea. In 1991, 11 turbines of 450 kW were installed at Vindeby, off the southern islands of Denmark. The turbines, which are still running efficiently today, gave Siemens a head start in offshore projects and provided a testing ground for offshore modifications. These modifications are now thoroughly proven and form the basis of today’s turbine technology. The mega farms of tomorrow have their roots in this h umble installation. Offshore wind turbines are growing Not only are offshore wind...

Open the catalog to page 11

Based on the proven technology of the SWT-3.6-107, the SWT-3.6-120 wind turbine featuring a 120-meter rotor was released in 2010. With this turbine, Siemens has p roduced a machine that can generate more power than its predecessor could at similar wind speeds. Basically, the main difference between the two machines’ core components is the rotor. The SWT-3.6-120 is equipped with 58.5-meter long rotor blades, giving it a swept area of 11,300 m2 or the equivalent to nearly two football fields. Lynn/Inner Dowsing, Great Britain 2008 Location: Rated capacity: Scope of supply: Distance to...

Open the catalog to page 12All Siemens Gamesa catalogs and technical brochures

-

SG 3.4-145

4 Pages

-

SG 14-222 DD

3 Pages

-

SG 14-236 DD

4 Pages

-

onshore product catalogue

12 Pages

-

SG 4.7-155

4 Pages

-

SG 2.6-114

4 Pages

-

SG 8.0-167 DD

2 Pages

-

SG 10.0-193 DD

3 Pages

-

SG 3.4-132

4 Pages

-

SG 2.6-126

4 Pages

-

SG 2.1-114

4 Pages

-

SG 4.5-145

4 Pages

-

SWT- DD -120

2 Pages

-

SG 2.7-129

4 Pages

-

SWT-7.0-154

4 Pages

-

Siemens D3 Platform

5 Pages

-

Siemens G2 Platform

5 Pages

-

Siemens G4 Platform

5 Pages

-

Siemens D7 platform

5 Pages

-

SWT-3.3-130

4 Pages

-

Introducing the SWT-2.3-120

4 Pages

-

Answers for energy

8 Pages

-

Siemens D6 Platform

8 Pages

-

Offshore service solution

7 Pages

-

Service solution

12 Pages

-

Onshore solution

12 Pages

-

SWT-6.0

16 Pages

-

SWT-3.6-120

10 Pages

-

SWT-3.0-101

8 Pages

-

SWT-3.6-107

8 Pages

-

SWT-2.3-113

8 Pages

-

SWT-2.3-108

8 Pages

-

SWT-2.3-101

8 Pages

-

SWT-2.3-93

8 Pages