Website:

sia Abrasives

Website:

sia Abrasives

Catalog excerpts

microtec Microabrasives for CR-Finishing® solutions

Open the catalog to page 1

sia Abrasives – Your key to a perfect surface Many materials hide a secret. They keep their real beauty hidden. Only a professional finish can reveal what is inside. sia Abrasives has devoted i tself to achieving perfectly finished surfaces for more than 135 years. “Finished by sia Abrasives” – the final touch makes all the difference to a wide variety of materials: wood acquires its expressive colour, striking colour contrasts with astounding grain, leather captivates with its subtle nuances, contact lenses ensure the very best acuity of vision, metal glows at the peak of its perfection,...

Open the catalog to page 2

microtec sia Abrasives CR-Finishing® solutions Products of sia Abrasives

Open the catalog to page 3

Top-quality products from Switzerland Company sia Abrasives is based in Frauenfeld, Switzerland, and is one of the world’s top three suppliers of innovative abrasives. It develops, manufactures and markets complete abrasive systems, customised to specific requirements and applications, for the treatment of every type of surface. Sanding has become a surface treatment technology. sia Abrasives employs about 1,310 people worldwide and is represented through local partners in more than 80 countries. Top-quality products from Switzerland Our careful choice of premium materials, the latest...

Open the catalog to page 4

Environmentally-friendly production, competent and ethical waste disposal For many years we have concerned ourselves with the efficient use of energy and committed ourselves to maintaining an intact environment. We have implemented many measures within our production processes to protect the air, land and water. We use our energy and raw-material resources efficiently and carefully. Monitoring raw materials, setting quality standards We manufacture top-quality products by thorough monitoring during the production p rocess. The superior properties of sia products represent excellent value...

Open the catalog to page 5

CR-Finishing® solutions Surface finishing technology CR-Finishing® (Constant Result Finishing) CR-Finishing® is a quality concept aimed at ensuring an efficient process which produces functional surfaces first time. Our microtec products have been designed specifically to suit application procedures, workpieces and - Constant and precise surface structures - Excellent cutting results - High material removal rates and finishing performance - High cost efficiency thanks to reduced process and retooling times - Defined and reproducible surface roughness Contact roller Centerless Pressure shoe...

Open the catalog to page 6

CR-Finishing® solutions Structure of microabrasives Grit selection Very high surface quality thanks to a unique grit selection The standard defined by sia Abrasives (microtec A specially developed high-tech grit selection in standard) is more precise than the FEPA-P stanaccordance with CIS (Calibration for Industrial dard. The CR-Finishing® grit therefore guaranStandards) ensures consistent and reproducible machining results. tees a consistent, first-class surface structure conforming to defined requirements. Not defined Nominal size Nominal size Your benefits: Perfect contact line thanks...

Open the catalog to page 7

CR-Finishing® solutions Rollers Product profile Copper rollers Chrome/hard chrome rollers Zinc rollers Hardened steel rollers Coated rollers (plasma ceramic/tungsten carbides) Rubber and plastic rollers Teflon rollers Perfect surfaces thanks to finishing process In the roller production process a perfect surface is a major factor when it comes to achieving concentricity, roundness, cylindricity and surface quality. To obtain constant and reproducible technical surfaces, sia Abrasives can supply state-of-the-art products which deliver consistent quality. This range of co-ordinated products...

Open the catalog to page 8

CR-Finishing® solutions Surface roughness according to use Chrome roller 5900 microtec – Electrostatically coated 5930 microtec – Slurry coated Dimensions: Cutting speed: Speed: Axial feed: Transitions: Contact roller: Oscillation: Contact pressure: Ø 40 mm x 250 mm length 12 cm / min 550 rpm 2.5 m / min 2x2 rubber, 65ShA 30 Hz 3 bar Hard chrome roller 5900 microtec – Electrostatically coated Ø 34 mm x 250 mm length 12 cm / min 550 rpm 2.5 m / min 2x2 rubber, 65ShA 30 Hz 4 bar Copper roller 5930 microtec – Slurry coated Grit range Dimensions: Cutting speed: Speed: Axial feed: Transitions:...

Open the catalog to page 9

CR-Finishing® solutions Vehicles and machines Product profile: Camshafts Crankshafts Steering components Shock absorber parts Valves Hydraulic components Pneumatic components Ball bearings High load and endurance strength Reproducible surfaces permit defined tolerances. This is essential for the production of precision components in the machine and vehicle manufacturing industries. Finishing is the key to the production of consistent and reproducible technical surfaces. The co-ordinated products from sia Abrasives deliver the consistent quality needed to achieve high cost efficiency in the...

Open the catalog to page 10

CR-Finishing® solutions Watches Product profile: Watch cases and bracelets Create an emotional impact with perfect surface finishes Perfect visual finishes are an absolute must in the watch and jewellery industry. The most suitable finishing product depends on the desired final result and the material to be worked. To ensure a perfect finish, sia Abrasives delivers the right products for any application. Product profile: Test specimens etc. Production technology Finishing of test specimens is key in the research & development of technology for the production of complex alloys and innovative...

Open the catalog to page 11

CR-Finishing® solutions Fibre optics Product profile: Ceramic/fibreglass terminations sia Abrasives fibre optic polishing system The polishing process is an important stage in the production of ferrule terminations. For this purpose, sia Abrasives delivers suitable products which offer consistent quality. High cost efficiency is achieved in ferrule production by co-ordinating the individual work steps. The following application recommendation applies to the most widely used polishing machines. Our high-performance polishing system will help you to produce highquality terminations which meet...

Open the catalog to page 12All Sia Abrasives catalogs and technical brochures

-

General Fabrication

48 Pages

-

High-tech belts

24 Pages

-

siaslide Pad S

2 Pages

-

Film sanding belts

4 Pages

-

Coatings and Composites

56 Pages

-

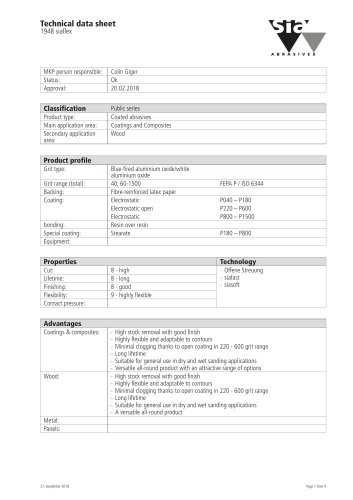

1948 siaflex

4 Pages

-

1931 siawat

3 Pages

-

1944 siaone

3 Pages

-

1913 siawat

4 Pages

-

1713 siawat

3 Pages

-

Metal

40 Pages

-

Wood

68 Pages

-

Automotive

52 Pages

-

sia Abrasives – key series

124 Pages

-

Belt sanding

24 Pages

-

Solid surfaces

16 Pages

-

FiboTec Multi-hole pattern

8 Pages

-

Bonded Abrasives

16 Pages

-

sia Abrasives Key Series

176 Pages

-

sia Abrasives New Products 2012

72 Pages