Website:

Shashin Kagaku

Website:

Shashin Kagaku

Catalog excerpts

Innovative and Advanced Planetary Mixer with degassing function Teams, Zoom, Skype, Team Viewer... On-line demo and meeting are available! (Sales Distributor) Shashin Kagaku Co., Ltd. Product Company 7-2-10, Nojihigashi, Kusatsu City, Shiga, 525-0058, Japan TEL. +81-77-566-1208 FAX. +81-77-565-3506 Kindly browse to our website for the latest information, inquiry and brochure about Kakuhunter

Open the catalog to page 1

Innovative and Advanced Planetary Mixer with degassing function Planetary mixer with degassing function can achieve optimization generated process for various materials. The Revolution-Rotation Motion Mixer & Degassing System"Kakuhunter" evolves following recent needs, besides, we also have been leading the market over supplying products with numerous variation. From now on, we will keep creating new value with our individual technology. Mixing Kneading Rotation Dispersion Emulsification Innovative and Advanced Planetary Mixer with degassing function Development history Since 90's, we have...

Open the catalog to page 2

Information equipment including mobile devices and tablet PCs essential to our life as well as automobiles and home information appliances which realize a comfortable life are supported by many high performance electronic components. Essentials in manufacturing these electronic components are expensive electronic materials, magnetic materials and Principal capability of Kakuhunter Mixing Material: Alumina Powder + Silicon Resin Material: High Viscosity Adhesive functional materials such as rare metals. Disadvantage of Other Method Applicable to motion mixing and degassing of various kinds...

Open the catalog to page 3

Disadvantage of Other Method Degassing Propeller Type Vacuum Degassing Machine Feature and Disadvantage ●Propeller part contacts the material, thus causing loss of material. ●Fluid level is raising so that it can be spilled out. ●Propeller shears composition, thus causing damage of material. ●It takes time to mix on high viscosity material and ●Accurate mixing is unable. would be hard to degas on bottom part. ●It takes time to degas, therefore operating efficiency is not good. ●It vaporized, then eventually decreased quantity. ●Composition can be changed depending on material. The Three...

Open the catalog to page 4

Revolution-Rotation Individual Control System Step Mode Enable to correspond for various demands of mixing and degassing by continuous driving with several different operational patterns. Fixed ratio for revolution-rotation Vacuum Reduced Pressure Function Exclusive Model Filling Machine Due to ratio change setup function of revolution speed and rotation speed, it is capable to operate with appropriate mixing and degassing in accordance with material feature for short time. Mass Production Model Vacuum Equipped Model Specific Model Standard Model Advanced Technology Disadvantage of Other...

Open the catalog to page 5

Revolution-Rotation Individual Control System 90 by combining both actions (except for some products). As 90 user defined channels (Except for some products) and 10 fixed data channels can be set as memory channels (recorded recipe for operation), this contributes to operational efficiency across a wide range of scenes from research and development to mass production basis. The individual setup of revolution and rotation speed allows for minimizing thermal elevation., then it enables to mix and degas preventing material from changing. Rotation 5 (Middle) Advanced Technology Except for some...

Open the catalog to page 6

Vacuum reduced pressure function Step Mode Vacuum reduced pressure function It enables to do voluntary setup of vacuum level over monitoring vacuum reduced pressure level, therefore enables removal of ultrafine bubbles. It can be expected to bring about effects of enhancement in conductivity and insulation capability required for electronic materials, Revolution (High) Rotation (High) Rotation (Middle) Revolution Setup Revolution (High) Rotation (Low) reduction in defect rates of products due to bubbles in optical materials and prevention of blank short of a syringe due to air bubbles. Only...

Open the catalog to page 7

Mass Production Model Specific Model Mass Production Model Standard Model Standard type equipped with individual revolution-rotation control system. (Except some machine model) Exclusive Model Filling Machine Vacuum Equipped Model 4L, 7L container or specific container are available, which is mass production model. Specific Model NEW To keep rotation direction is as usual, new function which revolving direction is changeable either clockwise or anti-clockwise for revolution. Under vacuum pressure, it may change material property, however it enables to achieve high precision degassing even...

Open the catalog to page 8

Anti-aggregation function High Dispersion function Rotation waving move function Weak revolution move function Ant-separation function Degas priority function Sustain separation for materials with different specific gravity. High speed mode with degas priority Mixing power and liquid, then avoid to occur lump condition. Sustain lump and separation, then enhance dispersion. Rotation speed creates up and down like wave, which enhances mixing force. ●Mode setting according to the purpose of use SK-300SII added Medium mode to existing mode (Mixing mode/ degassing mode). Easy operation keeps as...

Open the catalog to page 9

●Maximum throughput 2kg x 2 Cup ●Custom made mixing machine which correspond to customer's designated container. ●Maximum container size: Diameter 150mm, Height 170mm ●It enables to be equipped with several containers (while adapter is combined) and it contributes material loss due to right choice of container in following with production level. ●It enables to have certain throughput without adapter. Motion planetary mixer with mixing and degassing system New Technology (Changeable rotation function) equipped model! Mixing force 1.5 times, Degassing Force 1.4 times evolution! Disadvantage...

Open the catalog to page 10

On Delay ●Due to delay of entering moment of vacuum, then controls thermal elevation and composition change of materials. ●Controlling dispersion of fine powder when fine powder is mixing with liquid, it can also avoid short of dispersion, mixing and sticking fine powder to the container lid. Off Delay ●Due to delay of disappearing moment of vacuum, it extends degassing time till the rotation stops and can enhance degassing accuracy. Planetary Centrifugal Mixer With Vacuum Device Machine Vacuum equipped type Disadvantage of Other Method High capability vacuum reduced pressure function...

Open the catalog to page 11All Shashin Kagaku catalogs and technical brochures

-

Shashin Kagaku General Brochure

10 Pages

-

SK-400TR

2 Pages

-

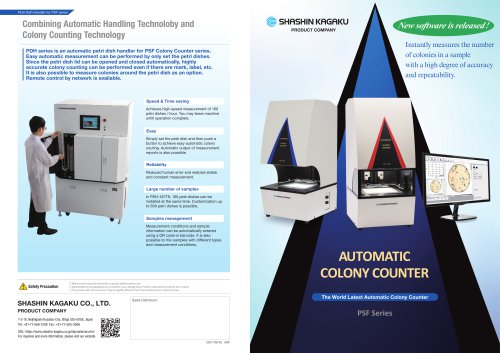

PSF series

4 Pages

-

PDH series

2 Pages