HK-8U Section automatic welding tractor with two torch holder and HK-8SS-N None blind area angle and no dead side end welding carriage tractor

1Pages

Catalog excerpts

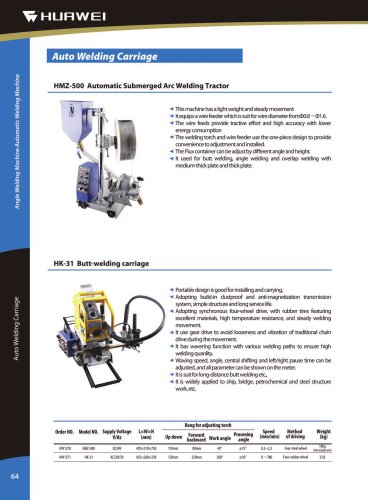

Auto Welding Carriage HK-8SS-N No-blind-area Welding Machine -4 The machine is used for angle welding, and a welding torch is designed to start moving when the tracker is not able to go forward. Therefore, the machine has able to weld front and rear area to prevent welding blind area. ■4 The machine is made with a small and compact structure, and it is easy to move and installed. *\ The machine has a stabilized voltage supply inside to prevent interference by the arc welding. Based on the works of magnet and guide wheel, the machine can track welding trajectory perfectly. < The machine uses a high-quality copper gear to avoid the magnetic interference of the magnet at the bottom of the tracker. Additionally, its rubber wheels are high temperature resistant. As a result, the tracker can move stably. Section Automatic Welding Carriage < Mainly sued for welding of U-shaped materials during bridge or box girder making; *• Small size, light weight, and integrated body which is solid and durable. < Low gravitational center design with built-in high strength magnet and the high temperature proof rubber wheel drive leads to stable running. < The X-Y adjustment of the welding pistol is very convenient, and support synchronous welding of two welding pistols, and also single welding pistol. ■4 Can conduct welding in both left and right directions, with both ends installed with the route sensing switch, which can make the trolley stop automatically upon ending of welding. < Possessing the function of arc welding, and improving the quality of welding line of arc. «» Can be widely applied to ship, bridge, engine, and steel structure work, etc. Rang for adjusting torch Order Model Supply Voltage LxWxH - Speed Method Weight NO. NO. V/Hz (mm) \iuiem Forward Work angle ProtMi"9 (mm/min) of driving (kg) backward angle

Open the catalog to page 1