Catalog excerpts

Gear Pumps

Open the catalog to page 1

rsssw^fDKA^ifMGRHtyaegg)* TS16949fDISO14OOOMti)iMGRHiS:^0!lfI)¥ft)i!)iy /jV wIfttgftfO©JiSttMGRH^IlEfS#^ft±gSS * GRHisitw^r: mi±£&m/K^3ffim/mi*3ffim/tm3$§m (^msm&EWHt) /mmm^ &»9§[W±gJlMEI««. Mlxi^ Ifl» tfffllfftS. GRH^SWiOS^iS iSi+^S^I±iMwttSarSigi+ffiAMM5tt0 IfcTttfiZGRHg^Jittrsa, GRHi£J§g/*&01MEg«j®E&tf: mmmmrjm, SEw^«GRH£®E^m^m£it75®Mt&GRH}£A^S£MM]0WJL grhr* )±iymESFiy^®E«st*®0wstt, , GRH£iM^E£$y&*®^75®EOTtEgs

Open the catalog to page 2

GRH is specialized in providing hydraulic components and solutions for hydraulic systems. With continuous improvement and enthusiasm over the past 30 years, GRH has developed into an emerging power in the fluid power industry since it was established in 1986. Research and development are the driving force that facilitates GRH’s ability to create new products. Standards of TS16949 and IS014000 are our guiding principles. Employees’ capabilities and creativity are major factors that differentiate GRH from our competitors. GRH designs and produces Hydraulic Gear Pumps & Motors, Monoblock...

Open the catalog to page 3

Gear Pump User Guide - ®In S’ 1

Open the catalog to page 4

GEAR PUMP USER GUIDE - Introduction of GRH Gear Pump - GRH ifi'f&iEMtf'' Gear pumps from GRH Hydraulic have a floating bushing feature with automatic axial clearance compensation. The bushings are made with special abrasion resistant material providing improved service life. Precisely machined gears ensure our units provide excellent low noise characteristics. Our cold extrusion motor bodies can endure pressures above 30Mpa. High strength cast iron front & rear covers also enhance our reliability. Our units are widely used in the industrial, mobile, marine and aerospace industries. 8s GRH...

Open the catalog to page 5

UvE mS^TtfiftTI#: ^ffiassb, 4£Sitte&. -n tn w jEm^m. Fluid must be specifically for hydraulic equipment, it must be nonfoaming, antioxidant, noncorrosive and have good lubricating features meeting the following requirements: aawfctt, ffijimtt. #i£smTfe*: Minimum Working Speed - IS We recommend a minmum working speed for every pump group as follows: OP: 800RPM IP: 600RPM IP—2. 5P: 500RPM 3P: 400RPM Hydraulic Circuit - & w co Avoid shard restrictions and small radius bends. Place safety relief valve set at correct pressure and with good dynamic characteristic. Recommended fluid speed in the...

Open the catalog to page 6

GEAR PUMP USER GUIDE it Hydraulic Circuit - u. a. m ftm ms. nus ‘smm&i'g&mfrn, hw^j^ibs. srMJi*£aAji*rir, msuim ai®ftffiA8~ioum„ ^Sltr^ScSliB], a#—a ft. GRH Gear Pump Characteristics - GRHiaffeS^tt By far largest number of premature failures of gear pumps are due to contamination; filtering with clogging indicating and alarms is recommended. The initial contamination of the fluid must not exceed class 10 NAS 1638. Pass experience has shown that even brand new fluid often exceed this value. In this case it is recommended below 60pm inlet side, and in the return side. nas 1638 log....

Open the catalog to page 7

GEAR PUMP USER GUIDE - Deliveries are carried out under the conditions of GRH. This catalogue is issued to provide outline information only. We reserve the right to change without any notice the design, features. Please contact us if you have special request.

Open the catalog to page 8

GEAR PUMP PERFORMANCE CURVES - ft 9k

Open the catalog to page 9

GEAR PUMP PERFORMANCE CURVES 1.60cc/r GEAR PUMP PERFORMANCE CURVES - It ft *£

Open the catalog to page 10

GEAR PUMP PERFORMANCE CURVES - ft ^ GEAR PUMP PERFORMANCE CURVES - ft *£

Open the catalog to page 11

GEAR PUMP PERFORMANCE CURVES - ■Q '5 2* i»

Open the catalog to page 12

BF Back inlet and front outlet ij/fiffi BO ?B BB Back inlet and back outlet jffiffiii/ftB BS Back inlet and side outlet tH SB Side inlet and back outlet {SliS/ptH SF Side inlet and front outlet {BliJfioiB SS Side inlet and side outlet fl!!)i#{!)!!l if] Y Relief valve ititfLl'f® D Check valve fn] |?5) / Omit

Open the catalog to page 13

B Bi-direction M Ini L CCW ffiBtff-R CW JfWff- BF Back inlet and front outlet jjf iffifo IB BB Back inlet and back outlet MffiJffltl BS Back inlet and side outlet /niffifllllB SB Side inlet and back outlet {RliSintB SF Side inlet and front outlet {!!B#0O lB SS Side inlet and side outlet Miffi'fflll IB F FPM seal MMM Omit NBR seal TMSUK Y Relief valve Stiff® D Check valve #- In] I'll / Omit

Open the catalog to page 15

1PF***L01B02 With Relief Valves - 1PF***L01B02-Y & Ci

Open the catalog to page 16

Function Code/5d Rotation/® |n] Seal/5fi?f Options/ P Single Pump L CCW F FPM seal MMM Y Reliefvalve I)P Double Pump R CW I® Bill Omit NBR seal TM-HkR D Check valve #-|h)M/ Omit 7[3;fj7|'fj| J»l« u 3i« I1'®

Open the catalog to page 17

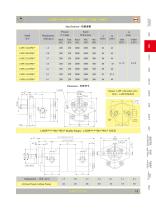

Dimension - $\SMR"vl" Pump Displacement - bij SCSIit(mi/r)

Open the catalog to page 19

Improve number/SScH^I Function Code/JMiH^ 55 Rotation/SS Ir] AT Cast iron covers P Single Pump B Bi-direction M |pj DP Double Pump MMttS L CCW it0ftff AB Rotaion could be changed R CW JfjRftff nTftSElnllnUjpM A Aluminum covers and body, bushing fpfujmi. u. * Options/nTH® Y Relief valve D Check valve #■ |r) |'fS| / Omit o. III Ports position/lft P lilt BS Back inlet and side outlet jp iSfl] hB SB Side inlet and back outlet ffjjjjfj tB SS Side inlet and side outlet F Seal/^jf F FPM seal Omit NBR seal

Open the catalog to page 21

Option: 1APF with relief valve J&I®: lAPF^M'itM

Open the catalog to page 22

F Function Code/IjjfeYtfi? Rotation/Sg[Fl Seal/®?itf P Single Pump DP Double Pump >S(S£t&ttK F FPM seal Omit NBRseal THiMtJK Y Relief valve SiflffSl D Check valve |b] |Y5| / Omit

Open the catalog to page 23

Improve number/65[fi4| Function Code/Ttjfi-fW? A Cast iron covers P Single Pump J^. DP Double Pump B Low noise gear pump TP Triple Pump 'fSBia'iSttK L Flelical gear pump Omit Aluminum covers fcttH/ii Rotation/SE [q] Ports position//^ P L CCW BB Back inlet and back outlet fsMfS fcB R CW Jl|jji0-j lf BS Back inlet and side outlet iuTifiJ] fcb SB Side inlet and back outlet ffjiiln LB SS Side inlet and side outlet fllfifiltB Bearing/^# SeaP®?it Options/ O Outboard bearing F FPM seal MM-fSt Y Relief valve i&ifft, fffij

Open the catalog to page 27All Shanghai Guorui Hydraulic Technology Co. catalogs and technical brochures

-

Hydraulic Power Units

24 Pages

-

3ADPF Double gear pump

2 Pages

-

BMRW

1 Pages

-

BMP

4 Pages

-

BM4

2 Pages

-

BM3

2 Pages

-

3FDF gear flow divider

1 Pages

-

1FDF gear flow divider

1 Pages

-

3.5MF hydraulic gear motor

1 Pages

-

2MF-B-O hydraulic gear motor

1 Pages

-

4W2448 hydraulic gear pump

1 Pages

-

3CPF H27 hydraulic gear pump

1 Pages

-

3APF Z05 hydraulic gear pump

1 Pages

-

3APF hydraulic gear pump

1 Pages

-

2PF Z03 hydraulic gear pump

1 Pages

-

2PF P02 hydraulic gear pump

1 Pages

-

1APF P01 hydraulic gear pump

1 Pages

-

1PF B02 hydraulic gear pump

1 Pages

-

0PF B01 hydraulic gear pump

1 Pages

-

2FDF hydraulic gear motor

1 Pages

-

BMT hydraulic gear pump

1 Pages

-

3MF hydraulic gear motor

1 Pages

-

2APF P02 hydraulic gear pump

1 Pages

-

DC-F39-2.5-E-2-24-8H-A

1 Pages