Catalog excerpts

Single Paper Sheet Feeder Transportation System With TIJ Inkjet Coding ------Max.780×780mm paper size LB-780pm sheet fed inkjet printing platform is a special equipment for inkjet printing and quality inspection. On the platform, you can install the inkjet printing system and the printing inspection system, which can realize the high-speed inkjet printing of lottery tickets, tickets, vouchers, votes and other products, or the product printing quality inspection after inkjet printing.

Open the catalog to page 1

1. Automatic paper feeding part: high speed and stable offset press feeder paper feeding. 2. Double sheet detection: ultrasonic double sheet detection, no manual adjustment after paper change. 3. Double sheet removal: automatic removal after ultrasonic detection of double sheets, no need to shut down to improve efficiency. 4. Side gauge deviation correction: adopt cable-stayed ball type deviation correction, accurate positioning. 5. Coding vacuum platform: the whole process suction synchronous belt conveyor is adopted to increase the paper stability and improve the coding and quality...

Open the catalog to page 2

Details of accessories Item Name of main parts Control system Servo system Touch screen Switching Mode Main motor Solenoid valve Technical parameter Item Maximum paper size Minimum paper size Stack height Total power Applicable paper

Open the catalog to page 3

Conveyor Belt With Vacuum adsorption Rectification Paper Piles Curing Rejection(if need) Double sheet rejection Feeder System

Open the catalog to page 4

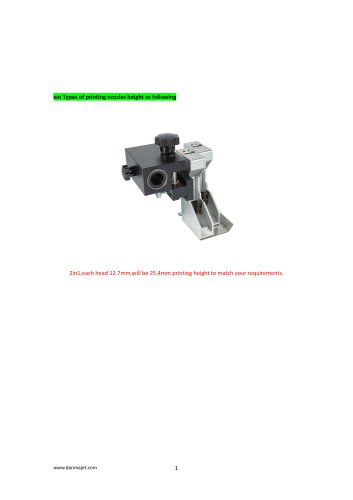

Product Features A) Using ink jet TIJ2.5 generation technology, a single print nozzle print height is 12.7 mm. B) A maintenance free disposable, print heads, long life print heads can print one Litre of ink. A) High resolution printing for bar code, 300* 300dpi to 600*600dpi. B) Can realize high-speed printing, the printing speed is from 30 meters/minute to 304 meters per minute. A) Computer as control center, control center and the system using gigabit Ethernet connection mode, each system controller can control 1 to 4 print heads. B) A control center can be 6 systems control/monitoring...

Open the catalog to page 5

D) Automatic compensation system to guarantees the highest bar code printing grade. E) Software has the function of preventing printed code, automatically identify print database, the software page shows printed bar code with different color to distinguish that is properly linked the data. F) System integration is high, easy installation and maintenance. G) Can be chosen the ink system, large capacity for ink (1 liter) to reduces the users intervention, decrease the cost of users at the same time, achieve 24-hour non-stop production. A) Editing interface content,no quantity limit, fully...

Open the catalog to page 6

Temperature 15 ℃ ~ 85 ℃, humidity 5% ~ 95%, no condensation environment. 12.Software technology parameters The operating system X Windows, Windows 7, Windows 8 (pro) Support the Dynamic text, counters, date, dynamic bar code, static text, pictures, (dynamic bitmap, need to customize) Support Bar code type 1d: EAN128, Code25, Code39, Code93, Code128, GS1Databar various one dimensional code; 2 d: PDF417, Data Matrix, Maxi Code, the QR Code and QR Code.

Open the catalog to page 7All Shanghai Danmajet Digital Tech Co. catalogs and technical brochures

-

MT-200 labeler

10 Pages