Catalog excerpts

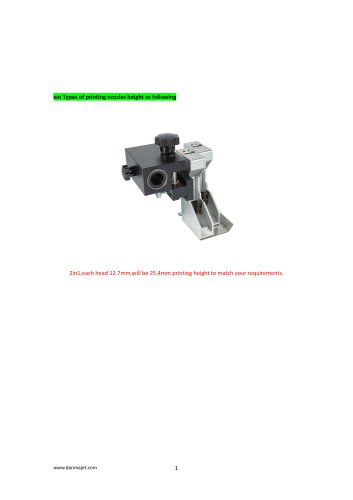

Bag sheet paging+Coding+Inspection System Overview of paging system 1. Paging: Forming a single sheet of stacked products through page headers and transferring them to the next workstation for coding, thereby reducing lightweight manual labor greatly improves production efficiency and coding accuracy. 2. Duplicate detection: Due to the physical characteristics of the product, there may be a probability of overlap (duplicate) during the splitting process when passing through the re inspection device workstation, an alarm will be triggered to stop the machine. Visual inspection is required for coding identification, and it is necessary to perform weight distribution inspection. If there is a complete duplication, the coding will only be printed on the first material on top, and visual inspection will not be able to detect the product on the bottom, resulting in missed spraying and printing. 3. Material shortage shutdown: Set the value according to our operating habits, in seconds. The paging head will stop independently when there is no material idle, to prevent unnecessary wear of the rubber pressure plate and paging toothed belt. We can also click the red stop button or the paging start stop button on the screen when collecting products at the back end, which can also prevent wear of vulnerable parts 4. Counting: Set the numerical value according to the user's required quantity. Accumulating the product count to the set value through the electric eye sensor will trigger an independent shutdown alarm. The cumulative quantity refers to the total accumulated quantity, which can also be reset by clicking the "Accumulate Reset" button on the screen. 5. Identification: Can be matched with small character coding machines, laser machines, labeling machines UV PIJ、 For high-resolution and other identification equipment, we will make corresponding choices based on the user's printing information, speed meter, printing

Open the catalog to page 1

height, product flatness and other needs. For example, the color of the conveyor belt surface, blue conveyor belt surface is suitable for laser machine matching, dark green conveyor belt surface is suitable for inkjet matching, laser machine needs to be equipped with laser pressure wheel, small character inkjet printer needs to be equipped with a digital display bracket for fixed adjustment of the print head, high-resolution needs to be equipped with an aluminum profile gantry bracket, and for products with relatively high flatness, we will add two short circular pressure strips at the back...

Open the catalog to page 2

4. Electrical control system PLC: Xinjie XD3 series Touch screen: Kunlun Tongtai TPC series 7-inch, multi product parameter memory function Air switch: Schneider DC power supply: Mingwei

Open the catalog to page 3All Shanghai Danmajet Digital Tech Co. catalogs and technical brochures

-

MT-200 labeler

10 Pages