Website:

Sesotec GmbH

Website:

Sesotec GmbH

Catalog excerpts

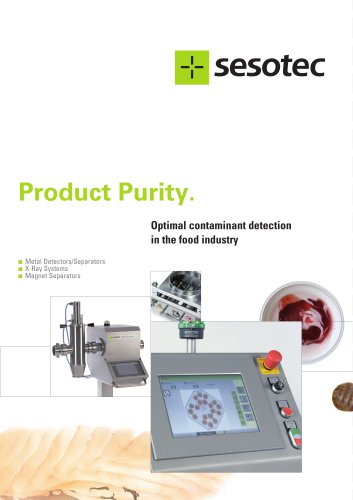

Product Purity. Optimal contaminant detection in the food industry Metal Detectors/Separators X-Ray Systems Magnet Separators

Open the catalog to page 1

Systematic metal and contaminant separation. Solutions for all process stages and conveying types Effective and reliable detection and removal of ■ magnetic metals ■ non-magnetic metals (copper, brass, stainless steel etc) ■ contaminants (glass, stones, ...) ■ faulty products pure. Consumer protection in the food industry: Sesotec is a global leader in the development and manufacturing of detection and separation systems with significant expertise in a wide spectrum of technology and a product range that is almost unrivalled in versatility and quality. Sesotec supplies systems for all...

Open the catalog to page 2

For bulk materials Systems with eject flap or swivel funnel are used for the separation of metal contaminants from bulk materials in free fall. Using easily available standard connections such systems can be easily integrated into existing pipes. Our sophisticated design prevents backjamming, clogging, the formation of material deposits, allows thorough and time-saving inside cleaning. All the system components are designed to meet the stringent hygiene requirements in the food industry. Metal separators for bulk materials also can be integrated in horizontal, vertical, or inclined vacuum...

Open the catalog to page 3

For individually packed materials Metal detectors that are integrated in conveyor belt lines primarily are used for the incoming and outgoing inspection of packaged bulk materials and of individually packed materials. They can be combined with many types of customer-specific separating units (air blast nozzles, pusher, separating slides, ...). Complete systems – comprising conveyor belt, metal detector, and separating unit – guarantee highest operating reliability and detection accuracy. INTUITY Metal detector with highest metal detection performance and a high level of usability. VARICON...

Open the catalog to page 4

Sesotec RAYCON X-Ray product inspection system provides highly accurate inline detection of contaminants (magnetic and non-magnetic metals, glass, ceramics, stones, raw bones, PVC, and rubber). Other product defects, clumping, trapped air and underweight or overweight of products can also be detected. Reliable detection is even guaranteed in metallic or metallised packaging materials. For separating purposes standard and customer-specific separating units can be integrated. The product inspection system RAYCON D combines highest detection capability with an industrial design with focus on...

Open the catalog to page 5

For liquid and pasty products Metal separators for the inspection of liquid and pasty products such as soups, sauces, sausage meat, or jam, can be easily integrated in existing pipes by way of standardised pipe connectors. Optimally matched to the respective product properties, arc valves, piston valves, or ball valves are used for the separation of metal particles. The metal separator LIQUISCAN VF+ is suitable for vacuum fillers manufactured by Handtmann, Vemag, Rex, Frey and so on. Models with linking gear box for manual linking systems are partly available. For the separation of ferrous...

Open the catalog to page 6

Consumer protection. Product purity. An imperative in the food industry All the food, people eat, must be absolutely pure and clean. This is one of the most important principles of the food industry. One decisive criterion here is that your products leave your factory without any metal contaminations and other contaminants. This guarantees that consumers are safe from any health impairments and that your company is safe from a loss of confidence, product liability cases, and expensive product recalls. Quality assurance. IFS compliant production. Responsibility and economic success The...

Open the catalog to page 7

Operating Companies: United Kingdom info@sesotec.co.uk www.sesotec.co.uk Sesotec Sari Wasselone France info@sesotec.fr www.sesotec.fr Sesotec system world Removing contaminants: ■ metals ■ plastics ■ glass ■ ceramics, porcelain, stones ■ and many others Removing from (good material): ■ bulk materials ■ liquids and pastes ■ individually packaged product ■ packed and loose items Product types: ■ end-products (food, textiles, plastics etc) ■ industrial raw materials ■ recycled materials can be integrated into all types of conveyor systems Detecting and separating sub-standard products:...

Open the catalog to page 8All Sesotec GmbH catalogs and technical brochures

-

C-SCAN DLS

2 Pages

-

C-SCAN GHF

2 Pages

-

RAYCON D+HX Bulk

4 Pages

-

RAYCON D+MX Bulk

4 Pages

-

RAYCON D+HX Dual

4 Pages

-

RAYCON D+HXLW

4 Pages

-

RAYCON D+MXLW

4 Pages

-

RAYCON D+HX

4 Pages

-

RAYCON D+MX

4 Pages

-

RAYCON EX1

4 Pages

-

VARICON COMPACT

2 Pages

-

ELCON

2 Pages

-

Systematic glass recycling

4 Pages

-

VARICON+

2 Pages

-

UNICON+

2 Pages

-

RAPID VARIO-FS

2 Pages

-

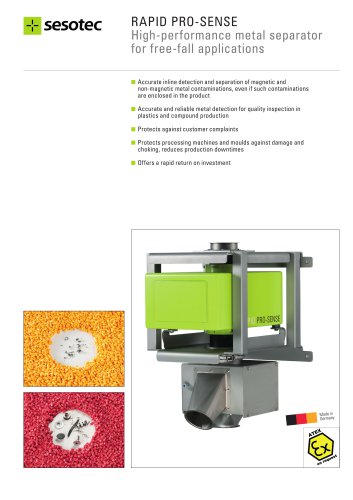

RAPID PRO-SENSE

4 Pages

-

RAPID DUAL

2 Pages

-

RAPID 8000

2 Pages

-

RAPID 6000

2 Pages

-

RAPID 5000

2 Pages

-

RAPID 4000

2 Pages

-

PROTECTOR

2 Pages

-

PROTECTOR-MF

2 Pages

-

SAFEMAG

2 Pages

-

LIQUISCAN VF+

2 Pages

-

PROTECTOR PROFESSIONAL

2 Pages

-

LIQUISCAN PL

2 Pages

-

INTUITY

2 Pages

-

GLS

2 Pages

-

GF

2 Pages

-

GF 4000

2 Pages

-

ELS

2 Pages

-

ASM VISION

4 Pages

-

LIQUIMAG

2 Pages

-

EXTRACTOR-SE

2 Pages

-

MAGBOX-MXP

2 Pages

-

MAGBOX-MXF FOOD/PHARMA

2 Pages

-

FLAKE PURIFIER+

2 Pages

-

K9

2 Pages

-

SPEKTRUM

2 Pages

-

VARISORT

2 Pages

-

VARISORT COMPACT

2 Pages

-

ASM QUASAR

4 Pages

-

Metal & E-Scrap Recycling

4 Pages

-

All about PET.

8 Pages

Archived catalogs

-

RAYCON 130/240

4 Pages

-

MAGBOX FOOD

2 Pages

-

C-SCAN DLS

2 Pages

-

RAPID PRO SENSE

4 Pages

-

RAYCON

6 Pages

-

LIQUIMAG AUTO-CLEAN

2 Pages

-

X-Ray Scanner

6 Pages