Website:

SERVOMEX

Website:

SERVOMEX

Group: Spectris

Catalog excerpts

Product overview Hazardous area Accurate and adaptable photometric analyzer for single component process monitoring Unrivalled performance Process control Corrosive Liquids Process control The new SpectraExact 2500F series of digital NDIR analyzers builds on the proven measurement principles of Servomex’s premium photometric analyzers Suitable for mounting in various hazardous area locations Highly reliable, accurate and stable Flexible On line, real time analysis SENSING TECHNOLOGY Easy to use Gas Filter Correlation New and improved, easy to use display and interface Modbus TCP Ideal for diverse gas and liquid sample types (0-180°C/32-356°F and 0-150psig/0-10barg/01,000kPag) Low cost of ownership Footprint compatible with all previous series of 2500 analyzers making for fast, cost effective replacement Separate cell allows simple cleaning and servicing Low maintenance nondepleting technology Benchmark compliance UKCA and CE-marked, ATEX, UKEx, IECEx hazardous area approvals North American hazardous area approvals* Hardware safety integrity certification supports use in SIL 2 safety instrumented systems* Certified for gases and dust Suitable to measure a continually flammable sample in a hazardous area Key applications Water in ethylene dichloride/solvents Ethylene production Toluene di-isocyanate production Pure Terephthalic Acid (PTA) production Note: * Pending, refer to Servomex For more information visit servomex.com/contac

Open the catalog to page 1

SpectraExact 2500F Enhanced safety for the most dangerous locations When you work on applications with complex process requirements, you need a highly flexible, easy-to-use solution that is adaptable to your exact process monitoring needs. Product overview Hazardous area Useful links: The SpectraExact 2500F is certified for gas and dust zone areas and is suitable to use with flammable or highly toxic gases. More features, more flexibility Digital communications enables the full functionality of the SpectraExact 2500F to be controlled remotely and safely, with Modbus implemented through...

Open the catalog to page 2

Technical data sheet See “typical measurements” on next page Non-dispersive infrared Performance Intrinsic error (accuracy) Drift (zero) per week Output fluctuation (noise) Ambient temperature influence Less than 1% FS zero drift due to rate of ambient temperature change of 25ºC/hr (45ºF/hr) over a maximum of 25ºC (45ºF) change Min. recommended range (application dependent) Recommended calibration frequency Application dependent Cross sensitivity Application dependent Signal outputs/inputs Analog outputs Output range Analog output parameters freely selectable over measurement range Alarms &...

Open the catalog to page 3

Physical Weight Dimensions, WxDxH Max: 1620 x 284 x 500mm (63.7 x 11.2 x 20.0”) (inc. allowance to open covers) Min: 620 x 284 x 241mm (24.2 x 11.2 x 9.5”) Utilities Supply voltage Rated power 120VA without optional heated cell Typically nitrogen/liquid - application dependent Gas/liquid - application dependent Sample connection 300VA with optional electrically heated cell Acetaldehyde Acetic Acid Acetone Acetylene Ammonia Benzene Butane Carbon dioxide Carbon disulfide Carbon monoxide Carbonyl sulfide Chloroform Ethane Ethanol Ethylene Ethylene oxide Freons Hexane Hydrogen chloride...

Open the catalog to page 4

Configuration Measurement The choice of analyzer will depend on the measurement and application. What do you want to measure? What measurement range? What other gases are present? In what concentrations? What are the temperature, pressure, dew point and particulate loading of the sample? Common measurements include: % & ppm(v) carbon dioxide % & ppm(v) carbon monoxide % & ppm(v) methane %, ppm(v) & LEL total hydrocarbons % & ppm(wt) water in solvents (e.g. EDC) % & ppm(v) sulphur dioxide % & ppm(v) ethylene % & ppm(v) phosgene Other measurements are available. Contact your local Servomex...

Open the catalog to page 5

Questionnaire Measurement(s) Sample conditions psig barg Is there a sample conditioning system between the sample point and the analyzer? Yes No If yes, please provide further details in the box below. Background gases (If a sample system is installed, please give details of background gases and sample conditions at the outlet of the system. If no sample system is fitted, please show background gases and conditions at the sampling point) Approval type Is the analyzer to be installed in a hazardous area? Yes If yes, please provide further details Sample wetted materials Choose from the...

Open the catalog to page 6

Dimensional drawings Cable entry Cell Length Overall Length Hole Centers

Open the catalog to page 7

We’re ready to help Whatever your gas analysis requirements, wherever you are. These analyzers are not intended for any form of use on humans and are not medical devices as described in the Medical Devices legislation or regulation. Please note: Whilst every effort has been made to ensure accuracy, no responsibility can be accepted for errors and omissions. Data may change, as well as legislation, and you are strongly advised to obtain copies of the most recently issued regulations, standards and guidelines. This document is not intended to form the basis of a contract. Servomex has a...

Open the catalog to page 8All SERVOMEX catalogs and technical brochures

-

Service Guide Issue 4

13 Pages

-

Product Guide Issue 9

15 Pages

-

Gas Guide Issue 5

74 Pages

-

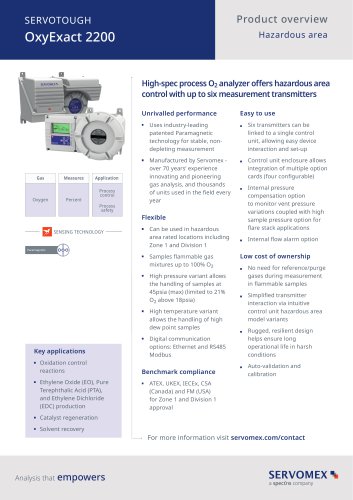

SERVOTOUGH OxyExact 2200

16 Pages

-

SERVOPRO 4900 Multigas

10 Pages

-

SERVOPRO PureGas

4 Pages

-

Servomex Product Portfolio

2 Pages

-

DF560E Operator Manual

144 Pages

-

DF-745 Operator Manual

112 Pages

-

ES 39 Sustainability

11 Pages

-

ES 38 Korea Special

19 Pages

-

ES 37 Clean Air part II

11 Pages

-

ES 36 Purity & Specialty

11 Pages

-

ES 35 Photometric Analysis

11 Pages

-

ES 34 70th Anniversary

15 Pages

-

ES30 Air Separation Units

11 Pages

-

ES 29 Clean Air

11 Pages

-

ES 28 Gas Analysis Applications

11 Pages

-

Sensing Technologies

13 Pages

-

DF760E Operator Manual

182 Pages

-

DF750 Operator Manual

112 Pages

-

DF745SGMax Operator Manual

90 Pages

-

DF-740 Operator Manual

87 Pages

-

DF-730 Operator Manual

82 Pages

-

DF560E Operator Manual 082616

146 Pages

-

DF550E Operator Manual 082616

134 Pages

Archived catalogs

-

SERVOFLEX MiniMP 5200

7 Pages

-

Servomex Gas Guide - Issue 4

76 Pages

-

Servomex Product Guide - Issue 8

15 Pages

-

Servomex Service Guide - Issue 3

13 Pages

-

SERVOTOUGH SpectraScan 2400

2 Pages

-

SERVOTOUGH H2 Scan

2 Pages

-

SERVOPRO NOx

4 Pages

-

SERVOPRO HFID

4 Pages

-

Servomex Service Portfolio

2 Pages

-

Servomex GAS GUIDE issue 3

77 Pages

-

Servomex Service Guide Issue 2

11 Pages

-

Servomex Product Guide Issue 7

13 Pages

-

Servomex Gas Guide 2022

65 Pages