Website:

SERVOMEX

Website:

SERVOMEX

Group: Spectris

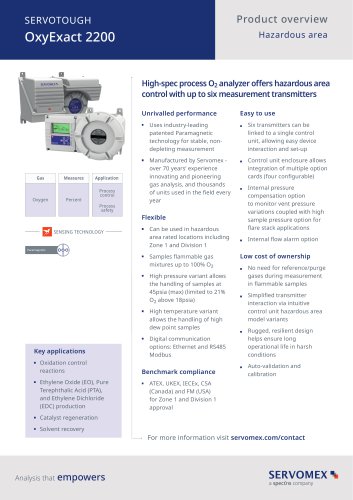

Catalog excerpts

Product overview Hazardous area High-spec process O2 analyzer offers hazardous area control with up to six measurement transmitters Unrivalled performance Process control Process safety SENSING TECHNOLOGY Uses industry-leading patented Paramagnetic technology for stable, nondepleting measurement Six transmitters can be linked to a single control unit, allowing easy device interaction and set-up Manufactured by Servomex over 70 years’ experience innovating and pioneering gas analysis, and thousands of units used in the field every year Control unit enclosure allows integration of multiple option cards (four configurable) Flexible Can be used in hazardous area rated locations including Zone 1 and Division 1 Samples flammable gas mixtures up to 100% O2 High pressure variant allows the handling of samples at 45psia (max) (limited to 21% O2 above 18psia) High temperature variant allows the handling of high dew point samples Key applications Oxidation control reactions Ethylene Oxide (EO), Pure Terephthalic Acid (PTA), and Ethylene Dichloride (EDC) production Digital communication options: Ethernet and RS485 Modbus Benchmark compliance Internal pressure compensation option to monitor vent pressure variations coupled with high sample pressure option for flare stack applications Internal flow alarm option Low cost of ownership No need for reference/purge gases during measurement in flammable samples Simplified transmitter interaction via intuitive control unit hazardous area model variants ugged, resilient design R helps ensure long operational life in harsh conditions Auto-validation and calibration ATEX, UKEX, IECEx, CSA (Canada) and FM (USA) for Zone 1 and Division 1 approval Catalyst regeneration Solvent recovery For more information visit servomex.com/contact

Open the catalog to page 1

OxyExact 2200 Unrivalled performance for the most demanding O2 process monitoring Product overview Hazardous area Useful links: When you work in hazardous area process monitoring applications, a highly accurate, safe O2 analytical solution that samples any flammable gas mixture up to 100% O2 is crucial. No matter what your monitoring requirement, you need an analytical solution that offers operational flexibility, exceptional safety and the opportunity to reduce costs. We don’t believe you should have to compromise. A no compromise solution The OxyExact’s sophisticated, flexible design...

Open the catalog to page 2

Technical data sheet SERVOTOUGH OxyExact 2200 Transmitter Specifications TRANSMITTER Measurement compartment operating temperature Performance Measurement range Minimum recommended range Intrinsic error (accuracy) Zero drift per week Span drift per week Linearity error 0.03% O2 <4 seconds at 250ml/min (standard flow range) <4 seconds at 1l/min (bypass option flow range) Response time (T90) Output noise (within any 5 minute period) Effect of ambient temperature changes Sample flow variations Effect of barometric pressure or sample vent pressure Zero change per 10°C (18°F) ambient change ±...

Open the catalog to page 3

Physical TRANSMITTER 2222H (high temperature) IP66, NEMA Type 4X Ingress protection Dimensions, WxDxH Wall mount Mounting Operating environment Temperature Atmospheric pressure Warm up time Useable immediately, but typically 2 hours (from 20°C) Typically 6 hours (from 20°C) Relative humidity Max altitude Sample condition TRANSMITTER 2223 (elevated sample pressure) 2222H (high temperature and elevated sample pressure) Maximum measurable oxygen concentration Inlet pressure Sample pressure (maximum) Inlet flow rate 250ml (air)/minute or 1l/min depending upon version 250ml (air)/minute or...

Open the catalog to page 4

Sample wetted materials TRANSMITTER 316 stainless steel Borosilicate glass Electroless nickel Platinum Platinum/iridium alloy Viton® 2223/2222H high pressure (solvent resistant)*‡ Hastelloy Internal flow pipework option alarm † (in addition) (in addition) Internal pressure compensation (in addition) Aluminia silicate glass Yttria stabilised zirconia * Special hydrogen resilient transducer option adds EPO-TEK® H72. Available as a special request only. ‡ Special chlorine resilient version replaces Viton®, Chemraz® 555 and PTFE (as appropriate) with Chemraz® 584. Available as a special request...

Open the catalog to page 5

Options Transmitter configuration Transmitter versions There are two versions of the OxyExact 2200. The 2223 measurement compartment is controlled at 60°C, whilst the 2222H measurement compartment operates at 110°C. The higher sample compartment temperature of the 2222H results in some options not being available for this transmitter unit. Transmitter certification Six certified versions of the OxyExact analyzer are available for the 2233 transmitter version: European ATEX, Great Britain UKEX, International IECEx, American FM, Canadian CSA and Japanese CML. Japanese certification is not...

Open the catalog to page 6

Configuration OxyExact 2223 variants: We have three pre configured 2223 OxyExact builds (SV01, SV02 and SV03) to cover the most common chosen option configurations to enable a quick turnaround from specification to delivery. The pre-configured standard variant 1 base level configuration, including the high pressure solvent resistant transducer, for general oxygen measurement requirements. The pre-configured standard variant 2 mid level configuration, adding internal flow alarm to the SV01 build, covering mid level process measurement needs. The pre-configured standard variant 3 full...

Open the catalog to page 7

Configuration OxyExact 2222H variants: We have two pre-configured 2222H OxyExact builds (SV01 & SV02) to cover the most common chosen option configurations to enable a quick turnaround from specification to delivery. The pre-configured standard variant 1 base level configuration, including the high-pressure solvent resistant transducer, for general oxygen measurement requirements. The pre-configured standard variant 2 mid-level configuration, adding internal flow alarm to the SV01 build, covering mid to high level process measurement needs. Other analyzer configurations not covered by one...

Open the catalog to page 8All SERVOMEX catalogs and technical brochures

-

Service Guide Issue 4

13 Pages

-

Product Guide Issue 9

15 Pages

-

Gas Guide Issue 5

74 Pages

-

SERVOPRO 4900 Multigas

10 Pages

-

SERVOPRO PureGas

4 Pages

-

Servomex Product Portfolio

2 Pages

-

DF560E Operator Manual

144 Pages

-

DF-745 Operator Manual

112 Pages

-

ES 39 Sustainability

11 Pages

-

ES 38 Korea Special

19 Pages

-

ES 37 Clean Air part II

11 Pages

-

ES 36 Purity & Specialty

11 Pages

-

ES 35 Photometric Analysis

11 Pages

-

ES 34 70th Anniversary

15 Pages

-

ES30 Air Separation Units

11 Pages

-

ES 29 Clean Air

11 Pages

-

ES 28 Gas Analysis Applications

11 Pages

-

Sensing Technologies

13 Pages

-

DF760E Operator Manual

182 Pages

-

DF750 Operator Manual

112 Pages

-

DF745SGMax Operator Manual

90 Pages

-

DF-740 Operator Manual

87 Pages

-

DF-730 Operator Manual

82 Pages

-

DF560E Operator Manual 082616

146 Pages

-

DF550E Operator Manual 082616

134 Pages

Archived catalogs

-

SERVOFLEX MiniMP 5200

7 Pages

-

Servomex Gas Guide - Issue 4

76 Pages

-

Servomex Product Guide - Issue 8

15 Pages

-

Servomex Service Guide - Issue 3

13 Pages

-

SERVOTOUGH SpectraScan 2400

2 Pages

-

SERVOTOUGH H2 Scan

2 Pages

-

SERVOPRO NOx

4 Pages

-

SERVOPRO HFID

4 Pages

-

Servomex Service Portfolio

2 Pages

-

Servomex GAS GUIDE issue 3

77 Pages

-

Servomex Service Guide Issue 2

11 Pages

-

Servomex Product Guide Issue 7

13 Pages

-

Servomex Gas Guide 2022

65 Pages