Website:

SERVOMEX

Website:

SERVOMEX

Group: Spectris

Catalog excerpts

Product overview Hazardous area Paramagnetic digital O2 analyzer designed for hazardous area use Unrivalled performance Application Process control Safety SENSING TECHNOLOGY Uses industry-leading patented Paramagnetic technology for stable, non-depleting measurement Manufactured by Servomex - over 70 years’ experience innovating and pioneering gas analysis, and thousands of units used in the field every year Flexible Can be used in locations up to Zone 1/Division 1 hazardous area rated Intelligent diagnostics and flow sensing Optimized for hazardous applications for example; safety critical oxidation, feedstock clean up, blanket inerting and flare stack analysis Low cost of ownership Key applications Process control Safety-critical oxidation, such as ethylene oxide and propylene oxide purity Flare stack analysis Vapor recovery No need for reference gases/purge gases during operation including use with flammable samples Easy to use Intuitive, engineer-friendly use and interaction Reduced requirement for a gas conditioning system for samples with a dew point of <50°C/122°F when sample heated option is used Unique FlowCube sensor technology provides unrivalled reliability and accuracy Intelligent pressure compensation for barometric and sample vent back pressure variations Benchmark compliance IECEx/ATEX/UKEX: for Zone 1, and cCSAus C1, D1 for North America SIL2 hardware compliance (Route 1H) functional safety manual available CE marked to meet: EU EMC Directive EU RoHS Directive Long calibration intervals and cell life Auto-validation reduces hands-on maintenance needs For more information visit servomex.com/contac

Open the catalog to page 1

Oxy 1900 Total safety in the most dangerous locations When you work with potentially dangerous, hazardous area applications, you need an O2 analytical solution that delivers benchmark safety compliance and complete reliability without question; product quality and plant safety depend on the equipment you integrate. The Oxy has ATEX/UKEX Cat. 2, IECEx Zone 1 and cCSAus Class 1, Div. 1 certification and is SIL2 hardware compliant (Route 1H), ensuring it offers solid, trusted reliablity in hazardous areas. Low maintenance, low cost of ownership Product overview Hazardous area Useful links: By...

Open the catalog to page 2

Technical data sheet Performance Measurement range Lower detection limit Linearity error Repeatability error Intrinsic error (accuracy) <±0.05% O2 (based on ±95% confidence limits) Zero drift per week Span drift per week Sample vent pressure effects Pressure compensation not fitted: 1% change in sample vent pressure corresponds to a 1% change in reading Pressure compensation fitted: 1% change in sample vent pressure corresponds to a 0.05% change in reading Sample flow variations A change in flow from 50-250ml/min (12-70l/hr internal bypass option) will cause a zero change of <0.1% O2 and a...

Open the catalog to page 3

Flow sensor Accuracy Minimum detectable change Response time Ambient temperature co-efficient span Calibration interval Sample condition The sample gas must be clean, non-corrosive and free from oil and condensates Particulate size Maximum sample dew point +5°C (+9°F) below minimum ambient temperature or +50°C (+122°F) (with optional sample heater fitted) Flow rates* Standard: Optional high flow internal bypass: Sample connection 1/4" NPT female, 6mm tube or 1/4" tube Maximum sample vent pressure* Maximum inlet pressure* 0.2kPa (0.03psi) relative to sample vent pressure‡ * The pressure and...

Open the catalog to page 4

Sample wetted materials Standard transducer Solvent resistant Solvent resistant, Internal flow transducer* hydrogen resilient alarm option (in transducer* addition) Aluminia silicate glass Borosilicate glass Electroless nickel Platinum/iridium alloy Pressure compensation option Yttria stabilised zirconia * Special chlorine resistant version replaces Viton with Chemraz® 584. Consult Servomex if required. Compliance Hazardous area approvals ATEX (Europe) UKEX (Great Britain) IECEx (International) cCSAus (North America) Class I, Div 1, Groups A, B, C, D T4 (-10°C ≤ Ta ≤ +60°C)* Class II, Div...

Open the catalog to page 5

Options Description Analyzer certification 5 certified versions of the Oxy analyzer are available: European, Great Britain, International, North American & Japanese. Supply voltage 2 versions of supply voltage are available: 100-120 and 220-240Vac. Stainless Steel pipework with Viton® seals. Stainless Steel pipework with Chemraz® and PTFE seals allowing enhanced solvent resistance. Sample flow Standard flow option of 150-250ml/min (200ml/min nominal). An internal bypass option allows inlet flows of 50 to 70 l/hr (60 l/hr or 1l/min nominal). Sample heating The measurement transducer in the...

Open the catalog to page 6

We have 4 pre configured Oxy builds (SV01, SV02, SV03 and SV04) to cover the most common chosen option configurations to enable a quick turnaround from specification to delivery. The pre-configured standard variant 1 base level configuration, including the solvent resistant transducer, for general oxygen measurement requirements. The pre-configured standard variant 2 mid level configuration, adding sample heating and auto validation/calibration to the SV01 build, covering mid level process measurement needs. The pre-configured standard variant 3 full configuration, adding pressure...

Open the catalog to page 7

Dimensional drawings Dimensions shown in millimetres Weight: 26kg nominal

Open the catalog to page 8

We’re ready to help Whatever your gas analysis requirements, wherever you are. These analyzers are not intended for any form of use on humans and are not medical devices as described in the Medical Devices legislation or regulation. Please note: Whilst every effort has been made to ensure accuracy, no responsibility can be accepted for errors and omissions. Data may change, as well as legislation, and you are strongly advised to obtain copies of the most recently issued regulations, standards and guidelines. This document is not intended to form the basis of a contract. Servomex has a...

Open the catalog to page 9All SERVOMEX catalogs and technical brochures

-

Service Guide Issue 4

13 Pages

-

Product Guide Issue 9

15 Pages

-

Gas Guide Issue 5

74 Pages

-

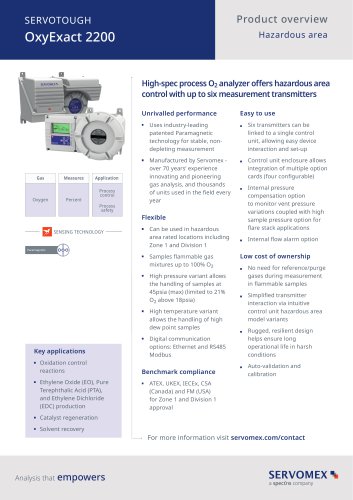

SERVOTOUGH OxyExact 2200

16 Pages

-

SERVOPRO 4900 Multigas

10 Pages

-

SERVOPRO PureGas

4 Pages

-

Servomex Product Portfolio

2 Pages

-

DF560E Operator Manual

144 Pages

-

DF-745 Operator Manual

112 Pages

-

ES 39 Sustainability

11 Pages

-

ES 38 Korea Special

19 Pages

-

ES 37 Clean Air part II

11 Pages

-

ES 36 Purity & Specialty

11 Pages

-

ES 35 Photometric Analysis

11 Pages

-

ES 34 70th Anniversary

15 Pages

-

ES30 Air Separation Units

11 Pages

-

ES 29 Clean Air

11 Pages

-

ES 28 Gas Analysis Applications

11 Pages

-

Sensing Technologies

13 Pages

-

DF760E Operator Manual

182 Pages

-

DF750 Operator Manual

112 Pages

-

DF745SGMax Operator Manual

90 Pages

-

DF-740 Operator Manual

87 Pages

-

DF-730 Operator Manual

82 Pages

-

DF560E Operator Manual 082616

146 Pages

-

DF550E Operator Manual 082616

134 Pages

Archived catalogs

-

SERVOFLEX MiniMP 5200

7 Pages

-

Servomex Gas Guide - Issue 4

76 Pages

-

Servomex Product Guide - Issue 8

15 Pages

-

Servomex Service Guide - Issue 3

13 Pages

-

SERVOTOUGH SpectraScan 2400

2 Pages

-

SERVOTOUGH H2 Scan

2 Pages

-

SERVOPRO NOx

4 Pages

-

SERVOPRO HFID

4 Pages

-

Servomex Service Portfolio

2 Pages

-

Servomex GAS GUIDE issue 3

77 Pages

-

Servomex Service Guide Issue 2

11 Pages

-

Servomex Product Guide Issue 7

13 Pages

-

Servomex Gas Guide 2022

65 Pages