Website:

SERVOMEX

Website:

SERVOMEX

Group: Spectris

Catalog excerpts

H2scan EXPLOSION-PROOF IN-LINE HYDROGEN PROCESS ANALYZER, USING A SOLID-STATE, NON-CONSUMABLE SENSOR CONFIGURED TO OPERATE IN PROCESS GAS STREAMS Flexible Easily configurable alongside SERVOTOUGH SpectraScan ‘Chip on a flex’ technology enables real-time operation Simple system integration EASY TO USE H2scan The H2scan hydrogen process analyzer features thin film technology that provides a direct hydrogen measurement that is not cross-sensitive to other gases. The H2scan is ideal for applications where real-time, hydrogen specific measurements can enhance process efficiencies, diagnostics and maintenance management. The H2scan does not require significant application development for each mix of hydrocarbon gases, yet it still exceeds industry standards. Used as a compliment to the light hydrocarbon analysis capability of the SERVOTOUGH SpectraScan, the combination of the two new and innovative technologies used challenges traditional GC analysis. By producing an accurate measurement at considerably faster speed, the H2scan/SpectraScan combination is a superior, yet simpler, detection for recycled and waste gas, and heating valve applications, achieved at considerably lower implementation and product lifetime costs. Field configurable settings via remote control interface Simple, in-line installation Low cost of ownership Low installation costs No reference or carrier gases Low lifetime cost-of-ownership in comparison to GC technologies Unrivalled performance Hydrogen measurement not crosssensitive to other gases Non-depleting sensing technology maintains performance without deterioration Benchmark compliance UL Class 1, Division 1, Groups B, C, D Learn more about the SERVOTOUGH H2scan

Open the catalog to page 1

PRODUCT DATA: H2scan Product Data: Hydrogen Range The H2scan Series includes sensor types that are designed for specific hydrogen ranges, corrosive gas tolerances and operation when no hydrogen is present. 1. 2710 products operated at 15psig will have a reduced H2 range of 0.1% - 10% H2 2. 2720 products may be operated in an Air, O2 or N2 background (see manual) o 3. Sensor performance specifications assume a dry process stream, and ambient temperature of 25 C, pressure compensation and are in addition to any errors in the calibration gases used. The accuracy is specified for the serial...

Open the catalog to page 2All SERVOMEX catalogs and technical brochures

-

Service Guide Issue 4

13 Pages

-

Product Guide Issue 9

15 Pages

-

Gas Guide Issue 5

74 Pages

-

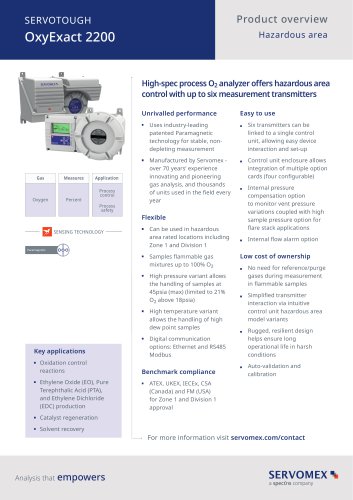

SERVOTOUGH OxyExact 2200

16 Pages

-

SERVOPRO 4900 Multigas

10 Pages

-

SERVOPRO PureGas

4 Pages

-

Servomex Product Portfolio

2 Pages

-

DF560E Operator Manual

144 Pages

-

DF-745 Operator Manual

112 Pages

-

ES 39 Sustainability

11 Pages

-

ES 38 Korea Special

19 Pages

-

ES 37 Clean Air part II

11 Pages

-

ES 36 Purity & Specialty

11 Pages

-

ES 35 Photometric Analysis

11 Pages

-

ES 34 70th Anniversary

15 Pages

-

ES30 Air Separation Units

11 Pages

-

ES 29 Clean Air

11 Pages

-

ES 28 Gas Analysis Applications

11 Pages

-

Sensing Technologies

13 Pages

-

DF760E Operator Manual

182 Pages

-

DF750 Operator Manual

112 Pages

-

DF745SGMax Operator Manual

90 Pages

-

DF-740 Operator Manual

87 Pages

-

DF-730 Operator Manual

82 Pages

-

DF560E Operator Manual 082616

146 Pages

-

DF550E Operator Manual 082616

134 Pages

Archived catalogs

-

SERVOFLEX MiniMP 5200

7 Pages

-

Servomex Gas Guide - Issue 4

76 Pages

-

Servomex Product Guide - Issue 8

15 Pages

-

Servomex Service Guide - Issue 3

13 Pages

-

SERVOTOUGH SpectraScan 2400

2 Pages

-

SERVOPRO NOx

4 Pages

-

SERVOPRO HFID

4 Pages

-

Servomex Service Portfolio

2 Pages

-

Servomex GAS GUIDE issue 3

77 Pages

-

Servomex Service Guide Issue 2

11 Pages

-

Servomex Product Guide Issue 7

13 Pages

-

Servomex Gas Guide 2022

65 Pages