Website:

SERVOMEX

Website:

SERVOMEX

Group: Spectris

Catalog excerpts

SERVOPRO PureGas OPERATOR MANUAL Part Number: Revision: Language:

Open the catalog to page 1

This page is intentionally blank

Open the catalog to page 2

SERVOPRO PureGas Gas Purifier This manual is copyright, and no part of it may be reproduced without Servomex’s written approval.

Open the catalog to page 3

SERVOPRO PureGas Gas Purifier Scope of this Manual This operation manual provides the information required to operate the purifier. This manual is not intended to provide servicing instructions to the user. The purifier should be operated only by personnel who are familiar with the procedures required for safe operation. It is strongly recommended that the factory be consulted before any maintenance or repairs are attempted. Safety Information This manual must be read and its contents fully understood before any attempt is made to install, operate or maintain the purifier. Important safety...

Open the catalog to page 4

SERVOPRO PureGas Gas Purifier 1.4 General Warnings and Cautions WARNING The purifier must only be used with inert gases. The intended gas type will be stated on the front of the purifier. Do not use any other gas type. This purifier should never be used to purify oxygen, air or other gas containing oxygen above trace levels. If this purifier is used to purify oxygen, air or other gas containing oxygen above trace levels, the purifier will rapidly and uncontrollably overheat and could cause a fire or permanent damage to the purifier, voiding the factory warranty. WARNING Improper...

Open the catalog to page 5

SERVOPRO PureGas Gas Purifier 1.5 The purifier is designed for the purification of carrier gases used in Gas Chromatography (GC).Outlet impurity levels for H2, O2, H2O, CO, CO2, CH4 (and N2 in noble gases) are reduced to low parts per billion (ppb) levels. The purifier comes completely assembled with a 1/8” compression fitting for both the gas inlet and the outlet. Both fittings are located on the top of the purifier. Optional 1/8” VCR connections are also available if requested. CAUTION The purifier does not incorporate integral flow or purity sensors. Therefore, it is the responsibility...

Open the catalog to page 6

SERVOPRO PureGas Gas Purifier Purifier height (envelope) Purifier width (envelope) Purifier weight Feed gas inlet Purified gas outlet Heater power consumption Particle filter Gas wetted surface finish 312 mm (~12.3 in) 347 mm (~13.67 in) [optional VCR connections] 112 mm (~4.4 in) 1.8 Kg (~4 lbs) 1/8” compression fittings (optional 1/8” VCR) 1/8” compression fittings (optional 1/8” VCR) 40 W 20 µm sintered filter on inlet and outlet Up and downstream of Getter vessels = 304L SST, all welded construction Environmental Limits Indoor Installation, Ambient Temperature (min – max) Operating...

Open the catalog to page 7

SERVOPRO PureGas Gas Purifier The sample gas must have a minimum purity of 5N (<10 ppm). Recommended gases to be purified Recommended input purity Expected output purity CAUTION The caps fitted to the gas inlet and outlet must be kept on until just prior to installation. The length of time that the purifier is left open to the air must be kept to a minimum, or the getter material may be prematurely depleted. The purge gas must have a minimum purity of 5N (<10 ppm). Recommended purge gas Recommended input purity Inlet/outlet flow rate Maximum inlet pressure Gas to be purified in process 5N...

Open the catalog to page 8

SERVOPRO PureGas Gas Purifier The level of performance depends upon the care and attention to the proper handling of the purifier. Exposure to non UHP environments, and physical contact of sealing surfaces will reduce the quality and life of the purifier. The purifier should be packaged and stored in a clean, dry environment until used. Do not open until the intended time of installation. WARNING Argon (Ar) is a simple asphyxiant. Exposure to atmospheres containing less than 19.5% oxygen may cause suffocation. Refer to the chemical supplier’s precautions and the material safety data sheet...

Open the catalog to page 9

SERVOPRO PureGas Gas Purifier A mounting bracket is supplied to simplify mounting. Any convenient location allowing the purifier to be mounted vertically is sufficient. Only mount the purifier in a vertical position. Overall dimensions for mounting of the standard and VCR versions are shown in figures 1 and 2 respectively. WARNING The purifier must be installed by a suitably skilled and competent technician or engineer in accordance with this manual. WARNING The purifier must be installed and operated in accordance with this and subsequent sections of the manual. Failure to do this may...

Open the catalog to page 10

SERVOPRO PureGas Gas Purifier Figure 1 – Overall and fixing dimensions (Standard)

Open the catalog to page 11

SERVOPRO PureGas Gas Purifier Figure 2 – Overall and fixing dimensions (VCR))

Open the catalog to page 12

SERVOPRO PureGas Gas Purifier Mechanical Installation and purging WARNING Do not remove any fittings or open any valves until the inlet and outlet lines are connected and purged. WARNING The purging process must be carried out at room temperature. Do not switch the purifier on at this stage. WARNING Ensure that the pipes to be connected to the purifier are routed so that they do not present a trip hazard to people. WARNING Purge and sample gases are asphyxiant in high concentrations. Ensure that the purge outlet pipe is vented to an area where the gases will not be a suffocation hazard to...

Open the catalog to page 13

SERVOPRO PureGas Gas Purifier Leak testing the purifier is recommended before activating. The purifier has -9 been certified helium leak tight to less than 10 scc/sec of He (inboard). Once installed, the purifier connections should be tested for leak integrity. The ventilation slots at the top and bottom of the purifier must not be obstructed. The wall fixings must be capable of supporting the purifier wall bracket, plus any connected pipes not supported by other means. Activation starts when the heater is plugged in. The purifier should be operated for at least two hours prior to injecting...

Open the catalog to page 14

SERVOPRO PureGas Gas Purifier 6 Disconnecting the Purifier WARNING Do not attempt to disconnect any of the components while the purifier is O in a heated (greater than 50 C) condition. Exposure of the getter alloy to atmosphere under these circumstances could be hazardous. If it is necessary to disconnect the purifier to carry out plant/factory maintenance, for example, and the purifier will not be used for several days, the following procedure must be followed: Prior to removal, the power must be shut off and the purifier allowed to cool to room temperature (this takes approximately 3...

Open the catalog to page 15All SERVOMEX catalogs and technical brochures

-

Service Guide Issue 4

13 Pages

-

Product Guide Issue 9

15 Pages

-

Gas Guide Issue 5

74 Pages

-

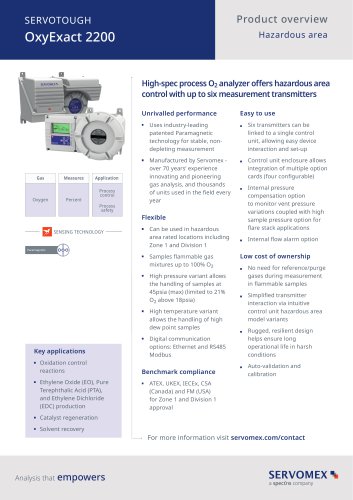

SERVOTOUGH OxyExact 2200

16 Pages

-

SERVOPRO 4900 Multigas

10 Pages

-

SERVOPRO PureGas

4 Pages

-

Servomex Product Portfolio

2 Pages

-

DF560E Operator Manual

144 Pages

-

DF-745 Operator Manual

112 Pages

-

ES 39 Sustainability

11 Pages

-

ES 38 Korea Special

19 Pages

-

ES 37 Clean Air part II

11 Pages

-

ES 36 Purity & Specialty

11 Pages

-

ES 35 Photometric Analysis

11 Pages

-

ES 34 70th Anniversary

15 Pages

-

ES30 Air Separation Units

11 Pages

-

ES 29 Clean Air

11 Pages

-

ES 28 Gas Analysis Applications

11 Pages

-

Sensing Technologies

13 Pages

-

DF760E Operator Manual

182 Pages

-

DF750 Operator Manual

112 Pages

-

DF745SGMax Operator Manual

90 Pages

-

DF-740 Operator Manual

87 Pages

-

DF-730 Operator Manual

82 Pages

-

DF560E Operator Manual 082616

146 Pages

-

DF550E Operator Manual 082616

134 Pages

Archived catalogs

-

SERVOFLEX MiniMP 5200

7 Pages

-

Servomex Gas Guide - Issue 4

76 Pages

-

Servomex Product Guide - Issue 8

15 Pages

-

Servomex Service Guide - Issue 3

13 Pages

-

SERVOTOUGH SpectraScan 2400

2 Pages

-

SERVOTOUGH H2 Scan

2 Pages

-

SERVOPRO NOx

4 Pages

-

SERVOPRO HFID

4 Pages

-

Servomex Service Portfolio

2 Pages

-

Servomex GAS GUIDE issue 3

77 Pages

-

Servomex Service Guide Issue 2

11 Pages

-

Servomex Product Guide Issue 7

13 Pages

-

Servomex Gas Guide 2022

65 Pages