Website:

SERVOMEX

Website:

SERVOMEX

Group: Spectris

Catalog excerpts

Product overview Ultra High Purity Ultra trace oxygen analyzer optimized for quality measurements in high purity electronic gases Unrivalled performance Highly sensitive 200ppt Lower Detection Level (LDL) Uses industry-leading, high stability coulometric sensor, with ultra-low drift SENSING TECHNOLOGY Fast speed of response in fluctuating O2 concentrations and flow conditions Quick upset recovery drydown avoids “running blind” when process problems occur Flexible Suitable for use H2, He, N2, Ar and other inert gases‡ Compact size and weight allows for mobile field use Flexible configuration options: initiation via front panel or digital communications Use in 18 different sample gases, standard with our gas scale factor feature Bench top, panel mount or rack mount options Easy to use Large color display, keypad, and intuitive software features Simple maintenance requirements Optional calibration system for compact integration onto the rear of the analyzer Low cost of ownership Long lasting coulometric sensor with five-year warranty Requires only an annual SPAN calibration and quarterly RSA fluid replenishment Hydrogen utility gas not required Long lasting high capacity purifier on optional calibration systems Benchmark compliance RoHS 3 and REACH IEC 61010-1 Overvoltage Category II, Pollution Degree 2 EU EMC Directive Key applications Quality control checks for electronics grade gases EU Low Voltage Directive ‡ Consult Servomex for other gases Leak detection for electronics grade gas lines For more information visit servomex.com/co

Open the catalog to page 1

Product overview Ultra High Purity High stability coulometric trace measurements When you work in quality control of electronic gases, you need an ultra-trace O2 contaminant detector and/or, a gas line leak detection analyzer. The DF-550E can deliver both with high performance, stable measurements in a light and flexible configuration. You need analysis that is both stable, reliable and ultra-sensitive; it needs to deliver consistent results - untroubled by changing sample and flow rate conditions - and be able to overcome upset events quickly and effectively. Flexibility is key and the...

Open the catalog to page 2

Technical data sheet Specifications Background gases H2, He, N2, Ar and other inert gases‡ Coulometric non-depleting electrochemical sensor Performance Measurement range Intrinsic error (accuracy) ±3% of reading or ±0.5ppb, whichever is greater <30 seconds typical, <45 seconds max Zero drift/month Lower detection limit (LDL) Display resolution Upset recovery time <15 minutes to return to within 15 ppb of previous stable reading Signal outputs/inputs Analog outputs 2 analog output options standard: isolated 4-20mA and 0-10V DC. Analog output can be configured to freeze during calibration...

Open the catalog to page 3

Physical Size Benchtop, panel mount or rack mount options Storage temperature Sensor storage conditions We recommend that the analyzer be operated as intended, within 6 months of delivery Utilities Supply voltage Sample wetted materials Analyzer fitted with Stainless steel, G10, Epoxy resin, Acrylic, Buna-N, and PVC This product complies with the EU EMC Directive, the EU Low Voltage Directive, Overvoltage Category II, Pollution Degree 2 and all other applicable CE directives. Electrical safety Dimensional drawings Dimensions shown in millimetres [

Open the catalog to page 4

Options Configuration options Sensor Stab-El sensor Power input 110 - 220 VAC universal input power Calibration system Not required Automated calibration system Manual calibration system Auto control of user-cal Standard capacity High capacity Case purge Panel mount Rack mount Bench top Flow alarm Relay contacts Four relay contacts Stainless steel outlet Downstream isolation valve UHP flow control valve High purity pressure regulator Power cord Not required USA Europe UK Not required Required Stainless steel tags Tag text - 01 Tag text - 02 Tag text - 03 Electrolyte type Electrolyte...

Open the catalog to page 5

We’re ready to help Whatever your gas analysis requirements, wherever you are. These analyzers are not intended for any form of use on humans and are not medical devices as described in the Medical Devices legislation or regulation. Please note: Whilst every effort has been made to ensure accuracy, no responsibility can be accepted for errors and omissions. Data may change, as well as legislation, and you are strongly advised to obtain copies of the most recently issued regulations, standards and guidelines. This document is not intended to form the basis of a contract. Servomex has a...

Open the catalog to page 6All SERVOMEX catalogs and technical brochures

-

Service Guide Issue 4

13 Pages

-

Product Guide Issue 9

15 Pages

-

Gas Guide Issue 5

74 Pages

-

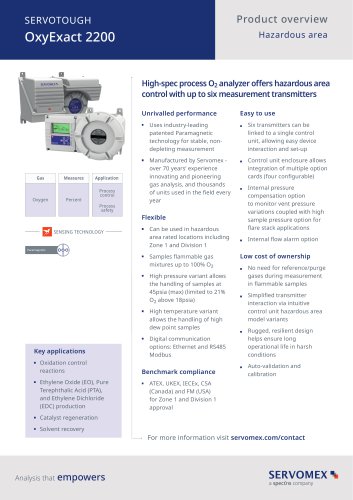

SERVOTOUGH OxyExact 2200

16 Pages

-

SERVOPRO 4900 Multigas

10 Pages

-

SERVOPRO PureGas

4 Pages

-

Servomex Product Portfolio

2 Pages

-

DF560E Operator Manual

144 Pages

-

DF-745 Operator Manual

112 Pages

-

ES 39 Sustainability

11 Pages

-

ES 38 Korea Special

19 Pages

-

ES 37 Clean Air part II

11 Pages

-

ES 36 Purity & Specialty

11 Pages

-

ES 35 Photometric Analysis

11 Pages

-

ES 34 70th Anniversary

15 Pages

-

ES30 Air Separation Units

11 Pages

-

ES 29 Clean Air

11 Pages

-

ES 28 Gas Analysis Applications

11 Pages

-

Sensing Technologies

13 Pages

-

DF760E Operator Manual

182 Pages

-

DF750 Operator Manual

112 Pages

-

DF745SGMax Operator Manual

90 Pages

-

DF-740 Operator Manual

87 Pages

-

DF-730 Operator Manual

82 Pages

-

DF560E Operator Manual 082616

146 Pages

-

DF550E Operator Manual 082616

134 Pages

Archived catalogs

-

SERVOFLEX MiniMP 5200

7 Pages

-

Servomex Gas Guide - Issue 4

76 Pages

-

Servomex Product Guide - Issue 8

15 Pages

-

Servomex Service Guide - Issue 3

13 Pages

-

SERVOTOUGH SpectraScan 2400

2 Pages

-

SERVOTOUGH H2 Scan

2 Pages

-

SERVOPRO NOx

4 Pages

-

SERVOPRO HFID

4 Pages

-

Servomex Service Portfolio

2 Pages

-

Servomex GAS GUIDE issue 3

77 Pages

-

Servomex Service Guide Issue 2

11 Pages

-

Servomex Product Guide Issue 7

13 Pages

-

Servomex Gas Guide 2022

65 Pages