Website:

SERVOMEX

Website:

SERVOMEX

Group: Spectris

Catalog excerpts

SERVOPRO Chroma OPERATOR MANUAL OPERATOR MANUAL Part Number: Revision: Language:

Open the catalog to page 1

SERVOPRO CHROMA Gas Analyser

Open the catalog to page 2

SERVOPRO CHROMA Gas Analyser TABLE OF CONTENT Section

Open the catalog to page 3

SERVOPRO CHROMA Gas Analyser

Open the catalog to page 4

SERVOPRO CHROMA Gas Analyser

Open the catalog to page 5

SERVOPRO CHROMA Gas Analyser

Open the catalog to page 6

SERVOPRO CHROMA Gas Analyser LIST OF TABLES Table name

Open the catalog to page 7

SERVOPRO CHROMA Gas Analyser LIST OF FIGURES Figure name

Open the catalog to page 8

SERVOPRO CHROMA Gas Analyser

Open the catalog to page 9

SERVOPRO CHROMA Gas Analyser 1 DESCRIPTION AND DEFINITIONS 1.1 Scope of this manual This manual provides installation, operation and routine maintenance instructions for the SERVOPRO Chroma Online Trace Gas analyser, abbreviated to “SERVOPRO Chroma” or “analysers” where applicable in the reminder of this manual. 1.2 Safety information Read this manual and ensure that you fully understand its content before you attempt to install, use or maintain the SERVOPRO Chroma. Important safety information is highlighted in this manual as WARNINGs and CAUTIONs, which are used as follows. WARNING...

Open the catalog to page 10

SERVOPRO CHROMA Gas Analyser 1.3 Description of Chroma Gas Analyser 1.3.1 Introduction The SERVOPRO Chroma is a 19” rack mounted online trace gas analyser, shipped pre-configured and requires little operator intervention. The analyser measures impurities in bulk gases, such as H2, O2, N2, Ar, CH4, CO, CO2 and NMHC impurities in H2, O2, N2, Ar or He background gas. The analyser configuration - form factor, detector(s), column(s), and valves - is application dependent. The analyser can be fitted with a number of detector types – Plasma Emission Detector (PED), TCD (Thermal Conductivity...

Open the catalog to page 11

SERVOPRO CHROMA Gas Analyser 1.3.2 Plasma Emission Detector (PED) The plasma emission detector (PED) is based on a spectroscopic emission cell, which is an established technique to measure impurities from the ppb to ppm level. The characteristics which make the plasma system stable and selective are the frequency, intensity, regulation, the coupling technique and the focusing (stabilizing) electrodes. The carrier gas flows at atmospheric pressure through a proprietary pure quartz cell. The cell is submitted to a high frequency high intensity electromagnetic field. This ionizes the carrier...

Open the catalog to page 12

SERVOPRO CHROMA Gas Analyser 1.3.4 Thermal Conductivity Detector (TCD) The Thermal Conductivity Detector (TCD) is a universal technique suitable to determine mixture of gases at percentage levels. The TCD compares the thermal conductivity of two gas flows – the pure carrier (reference) gas and the impurity eluting from the GC column. Changes in the temperature of the electricallyheated wires in the detector are affected by the thermal conductivity of the gas which flows around this. The changes in this thermal conductivity are sensed as a change in electrical resistance and are measured....

Open the catalog to page 13

SERVOPRO CHROMA Gas Analyser 1.3.8 I/O board The I/O board holds all the I/O functions of the instrument, shown in the table below. Digital I/O ❖ 6 oven temperature RTD input ❖ 8 isolated process 4-20 mA output 1 isolated digital input 8 remote range dry contact outputs 2 alarm dry contact outputs 1 system status dry contact output 1 extra relay 10 G.C. valve contact outputs 6 oven power relays All digital inputs and outputs, analogue inputs and outputs are transient and fuse protected. The I/O board is connected to an external 40 pin I/O connector through a flat cable connector The 40 pin...

Open the catalog to page 14

SERVOPRO CHROMA Gas Analyser 1.4 Description of Analyser Rear Connections 1.4.1 SERVOPRO Chroma Complete Rear Connections Figure 1 : SERVOPRO Chroma complete rear connections This rear panel is fitted to the master chassis, and to the secondary chassis in a system with a stand-alone PC. 1. Power inlet with switch and fuse 2. Gas trap inlet 3. RS-232/RS-485 socket 4. Auxiliary oven 5. RS-485 socket 6. Gas trap outlet 7. Ethernet port 8. USB port 9. Analogue 4-20 mA outputs 10. Digital outputs 11. Digital input 12. Earth terminals for cable screens 13. Carrier gas inlet to detector 1 14....

Open the catalog to page 15

SERVOPRO CHROMA Gas Analyser 1.4.2 SERVOPRO Chroma Reduced Rear Connections Figure 2 : SERVOPRO Chroma reduced rear connections This rear panel is fitted to the secondary chassis in a system with a master chassis. 1. Power inlet with switch and fuse 2. RS-485 3. Carrier gas inlet 4. Carrier gas vent 5. Detector 1 vent 6. Detector 2 vent 7. Sample gas vent 8. Sample gas inlet 1 (process) 9. Sample gas inlet 2 (span) Note: the RS-232 port is replaced with a RS-485 port on Secondary Chassis 1 on an analyser with multiple secondary chassis.

Open the catalog to page 16

SERVOPRO CHROMA Gas Analyser Gas connections when FID Detector is fitted Figure 3 : Gas connections when FID Detector fitted When a FID detector is installed in the SERVOPRO Chroma, the function of some of the rear gas connections are changed, as shown in Figure 3. 1. 2. 3. 4. FID Detector vent Fuel inlet Air inlet H2 contacts to control the fuel shut-off valve (see section 6.2.7) See Section 12 for more information on the FID detector.

Open the catalog to page 17

SERVOPRO CHROMA Gas Analyser 1.5 Auxiliary Oven 1.5.1 Description of Auxiliary Oven The Auxiliary Oven is an external module used when analysing N2 impurity in either H2 or O2 background gas. It is connected to the specific channel making the N2 determination, and removes the small volume of interfering background gas which has co-eluted with the N2 prior to the passing to the detector. 1.5.2 Auxiliary Oven Rear Connections Figure 4 : Auxiliary Oven rear connections 1. Power inlet 2. Oven inlet (connect to Trap In gas connector on Master or Secondary Chassis) 3. Oven outlet (connect to Trap...

Open the catalog to page 18

SERVOPRO CHROMA Gas Analyser Standalone PC Rear Connections Figure 5 : Standalone PC rear connections Power inlet with switch and fuse RS-232 port for remote terminal (marked “AUX”) RS-232 port for secondary unit (marked “TO ANALYSER”) USB port Ethernet port CAUTION To comply with the requirements of the EU EMC Directive, data cables used with the standalone PC (USB, Ethernet,) must be fitted with ferrite beads (Würth 74271131 or 74271221, depending on cable size), which should be clamped around 2 turns of cable. CAUTION To comply with the requirements of the EU EMC Directive, the front USB...

Open the catalog to page 19All SERVOMEX catalogs and technical brochures

-

Service Guide Issue 4

13 Pages

-

Product Guide Issue 9

15 Pages

-

Gas Guide Issue 5

74 Pages

-

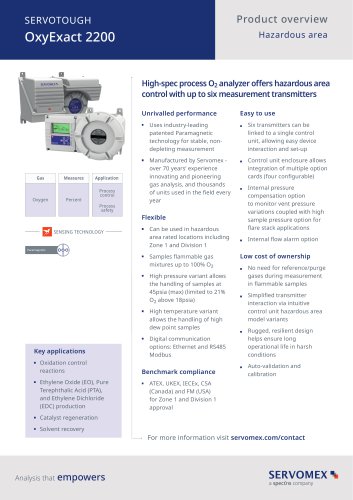

SERVOTOUGH OxyExact 2200

16 Pages

-

SERVOPRO 4900 Multigas

10 Pages

-

SERVOPRO PureGas

4 Pages

-

Servomex Product Portfolio

2 Pages

-

DF560E Operator Manual

144 Pages

-

DF-745 Operator Manual

112 Pages

-

ES 39 Sustainability

11 Pages

-

ES 38 Korea Special

19 Pages

-

ES 37 Clean Air part II

11 Pages

-

ES 36 Purity & Specialty

11 Pages

-

ES 35 Photometric Analysis

11 Pages

-

ES 34 70th Anniversary

15 Pages

-

ES30 Air Separation Units

11 Pages

-

ES 29 Clean Air

11 Pages

-

ES 28 Gas Analysis Applications

11 Pages

-

Sensing Technologies

13 Pages

-

DF760E Operator Manual

182 Pages

-

DF750 Operator Manual

112 Pages

-

DF745SGMax Operator Manual

90 Pages

-

DF-740 Operator Manual

87 Pages

-

DF-730 Operator Manual

82 Pages

-

DF560E Operator Manual 082616

146 Pages

-

DF550E Operator Manual 082616

134 Pages

Archived catalogs

-

SERVOFLEX MiniMP 5200

7 Pages

-

Servomex Gas Guide - Issue 4

76 Pages

-

Servomex Product Guide - Issue 8

15 Pages

-

Servomex Service Guide - Issue 3

13 Pages

-

SERVOTOUGH SpectraScan 2400

2 Pages

-

SERVOTOUGH H2 Scan

2 Pages

-

SERVOPRO NOx

4 Pages

-

SERVOPRO HFID

4 Pages

-

Servomex Service Portfolio

2 Pages

-

Servomex GAS GUIDE issue 3

77 Pages

-

Servomex Service Guide Issue 2

11 Pages

-

Servomex Product Guide Issue 7

13 Pages

-

Servomex Gas Guide 2022

65 Pages