Website:

SERVOMEX

Website:

SERVOMEX

Group: Spectris

Catalog excerpts

SERVOPRO 4900 Multigas Analyzer Installation and Operator Manual P/N: 0890000M

Open the catalog to page 1

IMPORTANT INFORMATION Continued safe and reliable operation of this equipment is conditional on all installation, operation and maintenance procedures being carried out in accordance with the appropriate manuals, by personnel having appropriate qualifications, experience and training. Failure to observe the requirements of the manual may result in the user being held responsible for the consequences and may invalidate any warranty. Servomex accepts no liability for unauthorized modifications to Servomex supplied equipment. Servomex has paid particular attention to Health and Safety...

Open the catalog to page 2

© Servomex Group Limited 2019

Open the catalog to page 3

© Servomex Group Limited 2019

Open the catalog to page 4

© Servomex Group Limited 2019

Open the catalog to page 5

© Servomex Group Limited 2019

Open the catalog to page 6

Introduction About this manual Scope of the manual This manual covers the installation, operation and routine maintenance of the 4900 Multigas analyzer. It is intended for those already familiar with the installation, use and maintenance of analytical or process instrumentation. General information on the analyzer is given in the main body of this manual. Transducerspecific information is contained in the relevant appendix at the rear of the manual. A separate Quick Start Guide is also supplied with the analyzer, reference part number 0890000Q. This details software configuration and...

Open the catalog to page 7

This symbol warns of specific hazards due to hazardous substances which, if not taken into account, may result in personal injury or death. This symbol warns of specific hazards due to caustic or corrosive substances which, if not taken into account, may result in personal injury or death. This symbol highlights where you must take special care to ensure the analyzer or other equipment or property is not damaged. Other information provided by the manual Note: Notes give extra information about the equipment. Hints give helpful tips and highlight information which is useful for you to be...

Open the catalog to page 8

The analyzer normally has one inlet and outlet stream carrying gas to all of the transducers at the same time. A second stream can be provided for the following configurations: a. If an external Nitrogen Dioxide (NO2) converter is to be used, a NO transducer will be fitted in the second stream for direct use with the NO2 converter. b. If an isolated dilution gas stream is used for O2/CO2 then a CO transducer can be fitted to the second stream. The standard unit weighs approximately 14 kg (30.9 lbs). When fitted with the extended chassis (required when multiple GFX sensors are chosen) this...

Open the catalog to page 9

• Each transducer is configured with one option board • Two alarms are activated (up to 8 alarms per option board, 32 max with 4 option boards) • OUTPUT: 1 Isolated 4-20mA (1 per option board, 4 max with 4 option boards) If Auto-Cal is purchased, then the following is included: • 8 Relays per transducer • 6th, 7th, 8th relays pre-assigned as Zero, Span, Sample gas per transducer • Software to allow auto-calibration / validation based upon a timer (gas switching is via user installed externally located valves). Options available per transducer: Additional option boards can be fitted to...

Open the catalog to page 10

Recommended calibration intervals For optimum performance, it is necessary to routinely check the calibration of all the internal gas transducers within the analyzer. The recommended periods for each transducer type are shown in Section 11.4. This manual provides details of the following: • the requirements for and configuration of calibration ancillaries (e.g. gases) • the setup of the auto-calibration / validation routines • the connection of external solenoid valves (when auto-calibration is used) • the use of the RS232 output and remote initiation of calibration • the use of Modbus or...

Open the catalog to page 11

Automatic calibration options Two functions are provided when the optional Auto-Cal feature is ordered. These functions are performed on the transducer. • Auto-calibration: Changes the actual calibration curve Auto-validation: Reads the value to determine if it is within the specified tolerance, making no changes to the calibration curve. Each transducer can have up to three sequences of auto-calibration or auto-validation attached to it. To use the auto-calibration/ validation routine, customer supplied solenoid valves will be controlled by discrete wiring to the relays for each of the...

Open the catalog to page 12

Figure 1-2: Rear of the 4900 Multigas Gas Analyzer configured for use with an external NO2 Converter (two inlet / outlet lines included) Note: The AquaExact 1688 port is not currently available for use in the 4900 Multigas. Figure 1-3: The Extended Chassis version of the 4900 Multigas Gas Analyzer Table 1-1 provides a general overview of the connectors on the back of the analyzer. Connections for optional features will be inactive unless the optional feature has been purchased. Table 1-1: Rear panel connections ID J9 – J16 Description Relay I/O connections Description Relay I/O connections...

Open the catalog to page 13

Option board 1&2 4-20 mA inputs Option board 3&4 4-20mA inputs 4 – 20 mA output / voltage output (I1± / V1±) 4 – 20 mA output / analog voltage output (I3± / V3±) 4 – 20 mA output / voltage output (I2± / V2±) 4 – 20 mA output voltage output (I4± / V4±) Profibus connector Ethernet connector AquaXact 1688 connector (not available at this time) Earth (ground) connection Sample requirements For best performance the flow supplied to the analyzer should be kept at a constant value and the analyzer must be freely vented to atmosphere, for both process sampling and for calibration gas input. Flow...

Open the catalog to page 14

Do not exceed the rated flow or pressure as transducer damage may result. Best practice is to place a pressure relief valve on the inlet line, venting any gas to a safe exhaust area. © Servomex Group Limited 2019

Open the catalog to page 15

Safety General warnings Before you attempt to install, commission or use the 4900 Multigas analyzer, read this manual carefully. Do not attempt to install, commission, maintain or use the 4900 Multigas analyzer unless you are trained and know what you are doing. The analyzer must be maintained by a suitably skilled and competent person. Do not connect the 4900 Multigas analyzer to a power source until all relays, input/ output signals and plumbing connections are made. This analyzer must be operated in a manner consistent with its intended use and as specified in this manual. The 4900...

Open the catalog to page 16All SERVOMEX catalogs and technical brochures

-

Service Guide Issue 4

13 Pages

-

Product Guide Issue 9

15 Pages

-

Gas Guide Issue 5

74 Pages

-

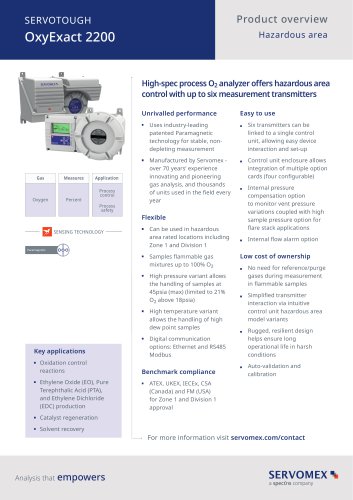

SERVOTOUGH OxyExact 2200

16 Pages

-

SERVOPRO 4900 Multigas

10 Pages

-

SERVOPRO PureGas

4 Pages

-

Servomex Product Portfolio

2 Pages

-

DF560E Operator Manual

144 Pages

-

DF-745 Operator Manual

112 Pages

-

ES 39 Sustainability

11 Pages

-

ES 38 Korea Special

19 Pages

-

ES 37 Clean Air part II

11 Pages

-

ES 36 Purity & Specialty

11 Pages

-

ES 35 Photometric Analysis

11 Pages

-

ES 34 70th Anniversary

15 Pages

-

ES30 Air Separation Units

11 Pages

-

ES 29 Clean Air

11 Pages

-

ES 28 Gas Analysis Applications

11 Pages

-

Sensing Technologies

13 Pages

-

DF760E Operator Manual

182 Pages

-

DF750 Operator Manual

112 Pages

-

DF745SGMax Operator Manual

90 Pages

-

DF-740 Operator Manual

87 Pages

-

DF-730 Operator Manual

82 Pages

-

DF560E Operator Manual 082616

146 Pages

-

DF550E Operator Manual 082616

134 Pages

Archived catalogs

-

SERVOFLEX MiniMP 5200

7 Pages

-

Servomex Gas Guide - Issue 4

76 Pages

-

Servomex Product Guide - Issue 8

15 Pages

-

Servomex Service Guide - Issue 3

13 Pages

-

SERVOTOUGH SpectraScan 2400

2 Pages

-

SERVOTOUGH H2 Scan

2 Pages

-

SERVOPRO NOx

4 Pages

-

SERVOPRO HFID

4 Pages

-

Servomex Service Portfolio

2 Pages

-

Servomex GAS GUIDE issue 3

77 Pages

-

Servomex Service Guide Issue 2

11 Pages

-

Servomex Product Guide Issue 7

13 Pages

-

Servomex Gas Guide 2022

65 Pages