Website:

SERVOMEX

Website:

SERVOMEX

Group: Spectris

Catalog excerpts

Operator Manual

Open the catalog to page 1

Copyright 2011 by Servomex Corporation No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form, or by any means including electronic, mechanical, photocopying, recording or otherwise without prior written permission of Servomex Corporation. Stablex, Bi-Strata and are trademarks of Servomex Corporation. VCR is a registered trademark of the Cajon Compa

Open the catalog to page 2

DF-560E Operator Manual Firmware v3.0.9 Version 100711 Your NanoTrace Oxygen Analyzer has been designed, manufactured and is supported under ISO-9001 controls, thus helping to insure the highest possible standards of quality. Every analyzer that Servomex manufactures is tested and operated on a variety of gas concentrations to insure that it functions properly when you receive it. The certificate of calibration assures your analyzer has been calibrated on gases that are traceable to NIST standards. With proper maintenance, your analyzer should remain calibrated for years. For a fast and...

Open the catalog to page 3

Read Me First… Unpacking Procedure Follow the procedure below to unpack your DF-560E Oxygen Analyzer. 1. Examine the condition of the packaging and its contents. If any damage is apparent, immediately notify the carrier and Servomex. Do not proceed with the installation. 2. Check the contents against the packing slip to make sure the shipment is complete. Unattached equipment may be shipped with the analyzer in supplemental packaging. Shortages should be reported to Servomex immediately. 3. All DF-560E analyzers are shipped with the following: Item One bottle of Hummingbird Brand...

Open the catalog to page 4

Unlike much UHP analytical equipment, DF-560E does not require constant maintenance. However the maintenance intervals for zero and span calibrations, as well as electrolyte and purifier maintenance, must be determined and followed carefully. Thank You Thank you for selecting the DF-560E Analyzer. Servomex designs, manufactures, exhaustively tests, and supports every analyzer under ISO-9001 control. You should expect every Servomex analyzer to arrive in perfect working order and, with good maintenance, provide years of trouble-free service.

Open the catalog to page 5

2 Cautions There are a number of warnings and cautions that must be observed to avoid damage to the analyzer as well to insure the safety of its users. The analyzer must be operated in a manner specified in this manual. Servomex cannot be responsible for direct or consequential damages that result from installing or operating the analyzer in a manner not described in this manual. Importantly, the analyzer has been designed for use with inert, non-toxic, non-combustible sample gases only. Servomex cannot be responsible for direct or consequential damages that result from using the analyzer...

Open the catalog to page 13

CAUTION Do not setup or operate the Oxygen Analyzer without a complete understanding of the instructions in this manual. Do not connect this Analyzer to a power source until all signal and plumbing connections are made. CAUTION This analyzer must be operated in a manner consistent with its intended use and as specified in this manual. DANGER The electrolyte is a caustic solution. Review the Material Safety Data Sheet (MSDS) before handling the electrolyte solution. The sensor is shipped dry and must be charged with electrolyte before it is operated. CAUTION Over-pressurizing the sensor can...

Open the catalog to page 14

EMI DISCLAIMER This Analyzer generates and uses small amounts of radio frequency energy. There is no guarantee that interference to radio or television signals will not occur in a particular installation. If interference is experienced, turn-off the analyzer. If the interference disappears, try one or more of the following methods to correct the problem: Move the instrument with respect to the receiver. Reorient the receiving antenna. Place the analyzer and receiver on different AC circuits.

Open the catalog to page 15

3 Specifications Range of Operation: 0-20ppm Lowest Detection Level (LDL): 75 ppt @ Constant Conditions Resolution (Smallest Detectable Change): 50 ppt Calibrated Accuracy: ±3 percent of reading or ±0.1 ppb (whichever is greater) @ Constant Conditions Response Time: Typically less than 15 seconds to read 90 percent of a step change. The equilibrium time is dependent on specific conditions. Upset Recovery Time: Typically less than 5 minutes from a high ppm upset to within 10 ppb of the previous stable reading. Ambient Operating Temperature: 0° C to 45° C (32° F to 110° F) Analog Output...

Open the catalog to page 17

Gas Flow Construction Materials: 300 series stainless steel 1/4-inch VCR-type compatible inlet fitting 1/8-inch compression outlet fitting orbital butt welded sample inlet assembly Calibration System Components: (Optional) Pneumatically or manually actuated springless diaphragm valve calibration system to provide zero and span calibrations. Orbital butt- welded assembly with one quarter inch VCR-type connections. Sensor Warranty: 5 years, limited. See Warranty section on page 129. Power Requirements: 100 to 120 Vac, 50/60 Hz, standard, .3 Amps 200 to 240 Vac, 50/60 Hz (optional), .15 Amps...

Open the catalog to page 18

Dimensions: 12.2-inch (30.9cm) wide x 8.9-inch (22.7 cm) high x 10.0-inch (25.4 cm) deep approximate (with handle and gas fittings) Weight: 18 pounds (8.2 kg) (approximate) - with optional manual calibration system add 2 pounds (.9 kg) - with optional automated calibration system add 4 pounds (1.8 kg) Figure 1: DF-560E Oxygen Analyzer

Open the catalog to page 19

4 Installation and Setup This procedure describes installation of the analyzer without options and with the voltage output set to 0-10 VDC. Options may affect the setup procedure described in this section. If your analyzer is equipped with options, refer to the appropriate section to determine changes to the setup. NOTE The screens shown in this manual have values that may not match the actual values displayed during your setup. Figure 2: Major Internal Components

Open the catalog to page 21

4.1 Adding Electrolyte DANGER The electrolyte is a caustic solution. Review the Material Safety Data Sheet (MSDS) before handling the electrolyte solution. NOTE The sensor is shipped dry and must be charged with electrolyte before it is operated. NOTE Use only E-lectrolyte Gold for the Platinum Series DF-560E Oxygen Analyzer. Failure to do so will void warranty. Install one bottle only. NOTE Do not apply power before adding electrolyte and thoroughly purging sample line. 4.1.1 Adding Electrolyte Procedure Follow this procedure to add electrolyte: 1. Remove the 13/16-inch inlet bulkhead...

Open the catalog to page 22All SERVOMEX catalogs and technical brochures

-

Service Guide Issue 4

13 Pages

-

Product Guide Issue 9

15 Pages

-

Gas Guide Issue 5

74 Pages

-

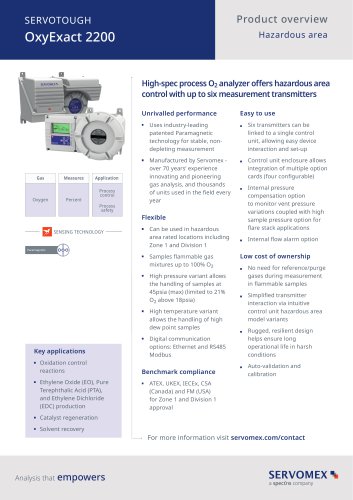

SERVOTOUGH OxyExact 2200

16 Pages

-

SERVOPRO 4900 Multigas

10 Pages

-

SERVOPRO PureGas

4 Pages

-

Servomex Product Portfolio

2 Pages

-

DF560E Operator Manual

144 Pages

-

DF-745 Operator Manual

112 Pages

-

ES 39 Sustainability

11 Pages

-

ES 38 Korea Special

19 Pages

-

ES 37 Clean Air part II

11 Pages

-

ES 36 Purity & Specialty

11 Pages

-

ES 35 Photometric Analysis

11 Pages

-

ES 34 70th Anniversary

15 Pages

-

ES30 Air Separation Units

11 Pages

-

ES 29 Clean Air

11 Pages

-

ES 28 Gas Analysis Applications

11 Pages

-

Sensing Technologies

13 Pages

-

DF760E Operator Manual

182 Pages

-

DF750 Operator Manual

112 Pages

-

DF745SGMax Operator Manual

90 Pages

-

DF-740 Operator Manual

87 Pages

-

DF-730 Operator Manual

82 Pages

-

DF550E Operator Manual 082616

134 Pages

Archived catalogs

-

SERVOFLEX MiniMP 5200

7 Pages

-

Servomex Gas Guide - Issue 4

76 Pages

-

Servomex Product Guide - Issue 8

15 Pages

-

Servomex Service Guide - Issue 3

13 Pages

-

SERVOTOUGH SpectraScan 2400

2 Pages

-

SERVOTOUGH H2 Scan

2 Pages

-

SERVOPRO NOx

4 Pages

-

SERVOPRO HFID

4 Pages

-

Servomex Service Portfolio

2 Pages

-

Servomex GAS GUIDE issue 3

77 Pages

-

Servomex Service Guide Issue 2

11 Pages

-

Servomex Product Guide Issue 7

13 Pages

-

Servomex Gas Guide 2022

65 Pages