Website:

SERVOMEX

Website:

SERVOMEX

Group: Spectris

Catalog excerpts

NanoTrace Moisture Analyzer DF-740 OPERATOR MANUAL

Open the catalog to page 1

Copyright 2011 by Servomex Corporation No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form, or by any means including electronic, mechanical, photocopying, recording or otherwise without prior written permission of Servomex Corporation. NanoTrace Moisture Analyzer is a trademark of Servomex Corporation. VCR is a registered trademark of the Cajon Company

Open the catalog to page 2

DF-740 Operator Manual Manual Version 120413 Your NanoTrace Moisture Analyzer has been designed, manufactured and is supported under ISO-9001 controls, thus helping to insure the highest possible standards of quality. Every analyzer that Servomex manufactures is tested and operated on a variety of gas concentrations to insure that it functions properly when you receive it. The certificate of calibration assures your analyzer has been calibrated on gases that are traceable to NIST standards. With proper maintenance, your analyzer should remain calibrated for years. For a fast and successful...

Open the catalog to page 3

Read Me First… Unpacking Procedure Follow the procedure below to unpack your NanoTrace Moisture Analyzer 1. Examine the condition of the packaging and its contents. If any damage is apparent, immediately notify the carrier and Servomex. Do not proceed with the installation. 2. Check the contents against the packing slip to make sure the shipment is complete. Unattached equipment may be shipped with the analyzer in supplemental packaging. Shortages should be reported to Delta F immediately. 3. All NanoTrace Moisture Analyzers are shipped with the following: Item Part Number Power cord with...

Open the catalog to page 4

Thank You Thank you for selecting the NanoTrace Moisture Analyzer. Seromex designs, manufactures, exhaustively tests, and supports every analyzer under the tightest quality controls. You should expect every Servomex analyzer to arrive in perfect working order and, with good maintenance, provide years of trouble-free service. Please call your nearest Servomex Business Center if you need assistance.

Open the catalog to page 5

3 Cautions There are a number of warnings and cautions that must be observed to avoid damage to the analyzer as well to insure the safety of its users. The analyzer must be operated in a manner specified in this manual. Servomex cannot be responsible for direct or consequential damages that result from installing or operating the analyzer in a manner not described in this manual. Importantly, the analyzer has been designed for use with inert, non-toxic, non-combustible sample gases only. Servomex cannot be responsible for direct or consequential damages that result from using the analyzer...

Open the catalog to page 13

CAUTION Do not setup or operate this analyzer without a complete understanding of the instructions in this manual. Do not connect this Analyzer to a power source until all signal and plumbing connections are made. CAUTION This analyzer must be operated in a manner consistent with its intended use and as specified in this manual. EMI DISCLAIMER This Analyzer generates and uses small amounts of radio frequency energy. There is no guarantee that interference to radio or television signals will not occur in a particular installation. If interference is experienced, turn-off the analyzer. If the...

Open the catalog to page 14

4 Specifications NOTE – All specifications assume Ammonia background gas. 4.1 Moisture Lowest Detection Level (LDL): 10 ppb @ Constant Conditions Resolution: Analytical (Smallest Detectable Change): 2 ppb Display: 100 ppt Accuracy: Greater of ±5% of reading or ± 5 ppb @ Constant Conditions Speed of Response: Typically 15 minutes to reach 90 percent of an upward step change Upset Recovery Time: Typically less than 5 minutes from a high ppb upset to within 10 ppb of the previously stable reading. Range: 0-10 ppm Background Gas Compatibility: Ammonia, Hydrogen, and Nitrogen gases Return...

Open the catalog to page 15

Audible/Visual Alarm Status Indicators: Four Moisture levels, Temperature, Moisture cell Diagnostic, Zero Verification or Calibration in Process, Moisture Analyzer off-line, Analog output freeze during calibration. Alarm Relays: Four non-latching, independently assignable to moisture alarms or to moisture calibration-in-process indicator. SPDT contacts rated at 1 Amp @ 30 VDC. Fail safe action upon loss of power to alarm condition. Not designed to switch AC power. Storage Temperature: Not to exceed 50° C (122° F) Construction: NEMA 1, 19 inch rack mount Dimensions: 19 inch (48.3cm) wide x...

Open the catalog to page 16

Figure 1: Overall View

Open the catalog to page 17

5 Installation, Start Up and Shut Down Installation of the analyzer requires the following steps be followed: Connecting the sample gas line to the inlet fitting Mounting the vacuum pump Connecting the line from the sample outlet to the needle control valve and vacuum pump Connecting the pneumatic pressure service to the pneumatic inlet fitting Making the power connection to the vacuum pump Making the power connection to the analyzer POWER SWITCH Figure 2: Major Internal Components Installation, Start Up and Shut Down

Open the catalog to page 19

5.1 Analyzer Installation 5.1.1 Gas Connections 5.1.1.1 Sample Gas Inlet Connection Sample gas is connected to the analyzer via a ¼ inch male swivel VCR fitting at the rear of the instrument as shown in Figure 3. Sample pressure of 9-15 psig is required and is regulated by a customer supplied regulator. Use a VCR filter gasket (supplied) to protect the gas delivery system from any particulate matter. Pre-purge the line with N2 gas by connecting to the analyzer (with a new VCR filter gasket) only finger tight and flowing gas for 15 minutes. When power is applied to the analyzer, the internal...

Open the catalog to page 20

PROCESS INLET PROCESS OUTLET Figure 3: Rear Panel Gas Connections and Controls Ø.28 [Ø7.14] 4 PL MOUNTING FOR BOTTOM OF BRACKET Ø.28[Ø7.14] 4 PL MOUNTING FOR REAR OF BRACKET Ø.28 [Ø7.14] 4 PL MOUNTING FOR LEFT OR RIGHT SIDE OF BRACKET Figure 4: Vacuum Pump Mounting Dimensions Installation, Start Up and Shut Down

Open the catalog to page 21

Figure 5: Vacuum Pump Installation 5.1.2 Electrical Connections Open the door and locate the power switch in the center of the upper rail. Be sure it is in the OFF position. Plug the supplied line cord (110VAC only) into the receptacle at the back of the analyzer. Verify the operating voltage is proper according to the label on the rear and connect the line cord to the power source. See Figure 6 Plug the vacuum pump power cord into a power receptacle capable of supplying a minimum of 5A at the appropriate voltage as indicated on the pump label. NOTE: Do not use the pump power receptacle on...

Open the catalog to page 22All SERVOMEX catalogs and technical brochures

-

Service Guide Issue 4

13 Pages

-

Product Guide Issue 9

15 Pages

-

Gas Guide Issue 5

74 Pages

-

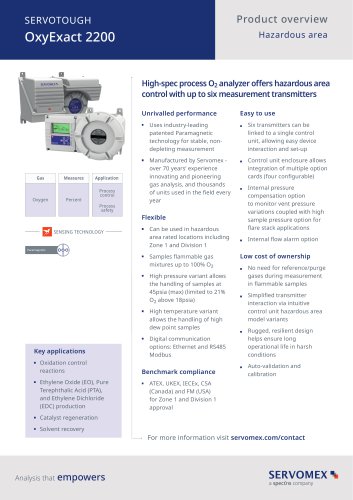

SERVOTOUGH OxyExact 2200

16 Pages

-

SERVOPRO 4900 Multigas

10 Pages

-

SERVOPRO PureGas

4 Pages

-

Servomex Product Portfolio

2 Pages

-

DF560E Operator Manual

144 Pages

-

DF-745 Operator Manual

112 Pages

-

ES 39 Sustainability

11 Pages

-

ES 38 Korea Special

19 Pages

-

ES 37 Clean Air part II

11 Pages

-

ES 36 Purity & Specialty

11 Pages

-

ES 35 Photometric Analysis

11 Pages

-

ES 34 70th Anniversary

15 Pages

-

ES30 Air Separation Units

11 Pages

-

ES 29 Clean Air

11 Pages

-

ES 28 Gas Analysis Applications

11 Pages

-

Sensing Technologies

13 Pages

-

DF760E Operator Manual

182 Pages

-

DF750 Operator Manual

112 Pages

-

DF745SGMax Operator Manual

90 Pages

-

DF-730 Operator Manual

82 Pages

-

DF560E Operator Manual 082616

146 Pages

-

DF550E Operator Manual 082616

134 Pages

Archived catalogs

-

SERVOFLEX MiniMP 5200

7 Pages

-

Servomex Gas Guide - Issue 4

76 Pages

-

Servomex Product Guide - Issue 8

15 Pages

-

Servomex Service Guide - Issue 3

13 Pages

-

SERVOTOUGH SpectraScan 2400

2 Pages

-

SERVOTOUGH H2 Scan

2 Pages

-

SERVOPRO NOx

4 Pages

-

SERVOPRO HFID

4 Pages

-

Servomex Service Portfolio

2 Pages

-

Servomex GAS GUIDE issue 3

77 Pages

-

Servomex Service Guide Issue 2

11 Pages

-

Servomex Product Guide Issue 7

13 Pages

-

Servomex Gas Guide 2022

65 Pages