Inline analytical technology for sulfuric acid and oleum: concentration and density, blending and warning limit detection

1 /

16Pages

Catalog excerpts

Sulfuric acid and oleum Inline analytical technology for: ·· concentration & density ·· blending ·· warning limit detect

Open the catalog to page 1

With high

Open the catalog to page 2

quality, saving resources: LiquiSonic®. h-value, innovative sensor technology. curate, user-friendly. LiquiSonic® is an inline analytical system for determining the concentration in liquids directly in the production process. The analyzer is also used for phase separation and reaction monitoring. Sensor installation within the product stream means an extremely fast measurement that responds immediately to process changes. User benefits include: ·· optimal plant control through online and real-time information about process states ·· maximized process efficiency ·· increased product quality...

Open the catalog to page 3

Inline process analysis

Open the catalog to page 4

Applications 1.1 Introduction 1.2 Sulfuric acid 1.3 Oleum 1.4 Sulfuric acid and oleum LiquiSonic® system 2.1 LiquiSonic® 20 and 30

Open the catalog to page 5

Optimal and reliable process control requires fast information through robust and rapid process analytical technology. The use of the LiquiSonic® analyzer and its easy integration into existing plant technology results in an improvement of the asset utilization, process safety and product yield under relatively low project costs. There are several industries where the LiquiSonic® systems for concentration measurement in sulfuric acid and oleum can be applied: ·· sulfuric acid and oleum production ·· synthesis gas drying in the chemical and petrochemical industry ·· ·etching and pickling...

Open the catalog to page 7

Oleum is produced by dissolving of SO3 (sulfur trioxide) in 100 % sulfuric acid. Often it is also referred as fuming sulfuric acid or disulfuric acid. In free SO3, typical measuring concentrations are from 0 wt% to 60 wt%, and for H2SO4 from 100 wt% to 115 wt%. For example, S03 is produced in the contact process by sulfur combustion. Thereby SO2 (sulfur dioxide) arises, which oxidize to SO3. Eventually, SO3 has to be collected in sulfuric acid as due to the intense exothermic reaction, a collection in water is not possible. The resulting oleum can be monitored inline by the LiquiSonic®...

Open the catalog to page 8

Sulfuric acid and oleum By mixing sulfuric acid with oleum, any concentrations of high concentrated sulfuric acid can be adjusted. The adjustment requires a continuous inline monitoring of the concentration. Furthermore, the oleum entails a potential hazard and should not occur in certain absorption processes. The warning signals integrated in the LiquiSonic® analyzer signalize this prematurely and the information will be sent to the process control system by the periphery of the analyzer. The ultrasonic sensor incorporates two temperature sensors determining accurately the temperature,...

Open the catalog to page 9

LiquiSonic® system The LiquiSonic® system consists of one or more sensors and a controller. The ultrasonic sensor has the actual ultrasonic measuring path and the highly precise temperature detection. The immersion sensor Ex 40-40 is especially used in hazardous areas and is approved by ATEX and IECEx certification zone 0 to 2. The sensor can be delivered with explosion protection type II 2 G EEx de IIC T3, T4, T5 or T6. The controller 30 is a highly efficient device which includes up to four sensors. They can be installed in different steps with a maximum distance of 1,000 m between...

Open the catalog to page 11

Enthusiasm for technical progress is the driving force behind our company as we seek to shape the market of tomorrow. As our customer you are at the center of all our efforts and we are committed to serving you with maximum efficiency. We work closely with you to develop innovative solutions for your measurement challenges and individual system requirements. The growing complexity of application-specific requirements means it is essential to have an understanding of the relationships and interactions involved. Creative research is another pillar of our company. The specialists in our...

Open the catalog to page 13

With inno

Open the catalog to page 14

ovative sensor technology. curate, user-friendly. SensoTech is a provider of systems for the analysis and optimization of process liquids. Since our establishment in 1990, we have developed into a leading supplier of process analyzers for the inline measurement of liquid concentration and density. Our analytical systems set benchmarks that are used globally. Manufactured in Germany, the main principle of our innovative systems is to measure ultrasonic velocity in continuous processes. We have perfected this method into an extremely precise and remarkably user-friendly sensor technology....

Open the catalog to page 15

SensoTech (Shanghai) Co., Ltd. 申铄科技(上海)有限公司 No. 35, Rijing Road, Pudong New District 上海市浦东新区外高桥自由贸易区日京路35号1241室 200131 上海,中国 China 电话 +86 21 6485 5861 传真 +86 21 6495 3880 sales-china@sensotech.com www.sensotechchina.com

Open the catalog to page 16All SensoTech catalogs and technical brochures

-

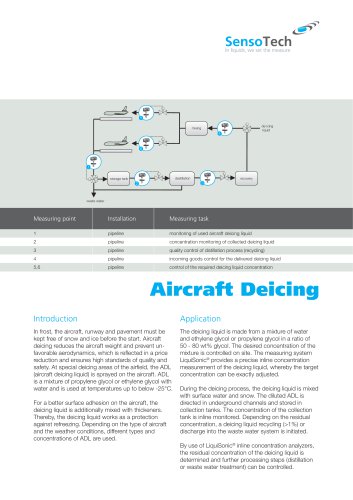

Aircraft Deicingy

3 Pages

-

Company Profile

8 Pages