Inline analytical technology for phase separation in pipelines, in batch processes, in continuous processes and as valve solution

1 /

12Pages

Catalog excerpts

Phase separation Inline analytical technology • in pipelines • in batch processes • in continuous processes • as valve sol

Open the catalog to page 1

Increase quality, save resources: LiquiSonic®. With high-quality, innovative sensor technology. Robust, precise, user-friendly. LiquiSonic® LiquiSonic® is an inline analytical system for determining the concentration in liquids directly in the production process. The analyzer is also used for phase separation and reaction monitoring. Sensor installation within the product stream means an extremely fast measurement that responds immediately to process changes. User benefits include: • optimal plant control through online and real-time information about process states • maximized process...

Open the catalog to page 2

Inline process analysis Content LiquiSonic®2 Process4 Phase separation in pipelines Phase separation in batch processes Phase separation in continuous processes LiquiSonic® system Accessories9 Controller and field housing

Open the catalog to page 3

Process Phase separation in pipelines The precise detection of different phases in a pipeline is necessary in various industries. Often different products flow through the same pipe, but every single product is supposed to end in a different location. In applications in which product A is discharged by product B, the intermediate phase is to be separated. For example, in breweries, different kinds of beer are bottled in succession, whereas the first and last runnings are removed from circulation and return into the brewing process. Safety aspects are relevant in applications with high-risk...

Open the catalog to page 4

Phase separation in batch processes In batch processes the product phases are separated due to the physical and chemical properties of each product. Application example 1: organics In the production of cosmetics, a salt-containing aqueous phase is separated from an primary product phase. The aqueous lower phase is disposed via sewage-works. The upper phase of the primary product is slightly hazardous to water and only moderately biodegradable. Therefore, this phase must not be discharged into sewage. The rapid and reliable detection of the primary product phase has the highest priority to...

Open the catalog to page 5

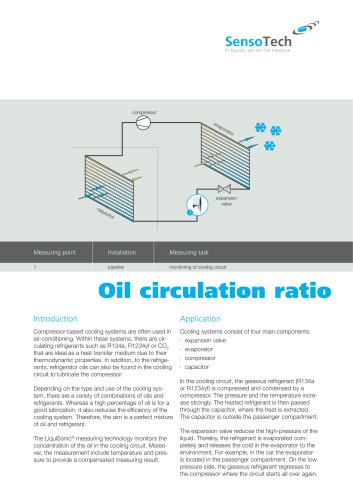

Phase separation in continuous processes In a continuous process, one or more sensors control the separation of a process stream. In this case, only the phase-specific value of sonic velocity is monitored and kept constant. Often, the product concentration of the carrier phase varies in the inlet. This quickly shifts the height of the phase boundary. Thus, the carrier phase could be pulled off with the product, which greatly affects the purity. In process the separation is made via one pump in each of the two outlet pipes. In this way, for example, the continuous separation of a reaction...

Open the catalog to page 6

LiquiSonic® System LiquiSonic® 30 The LiquiSonic® 30 system consists of one or more senors and one controller. Each sensor works autonomously and can be used in different applications. The liquid-wetted parts of the sensor are made of stainless steel DIN 1.4571 as standard. In chemical aggressive liquids the sensor is made of special corrosion-resistant material. The rugged, completely enclosed design requires no gaskets or “window”, making it totally maintenance-free. Additional sensor features such as flow / stop or full / empty pipe monitoring greatly advance process control. The...

Open the catalog to page 8

Accessories Controller and field housing The controllers are designed for rack-mounted systems. It is also available with a 19“ housing 3RU. In order to be able to mount controllers into the field, two variants of field housings made of plastic or stainless steel can be delivered, which meet on-site conditions in an optimal way. Fieldbus The fieldbus option provides the possibility to integrate the controller in a PCS or to automate the process flow via PLC. Beside the transfer of measuring values like concentration and temperature it is also possible to exchange parameters and control data...

Open the catalog to page 9

Quality and Support Enthusiasm for technical progress is the driving force behind our company as we seek to shape the market of tomorrow. As our customer you are at the center of all our efforts and we are committed to serving you with maximum efficiency. We work closely with you to develop innovative solutions for your measurement challenges and individual system requirements. The growing complexity of application-specific requirements means it is essential to have an understanding of the relationships and interactions involved. Creative research is another pillar of our company. The...

Open the catalog to page 10

In liquids, we set the measure. With innovative sensor technology. Tough, accurate, user-friendly. SensoTech SensoTech is a provider of systems for the analysis and optimization of process liquids. Since our establishment in 1990, we have developed into a leading supplier of process analyzers for the inline measurement of liquid concentration and density. Our analytical systems set benchmarks that are used globally. Manufactured in Germany, the main principle of our innovative systems is to measure ultrasonic velocity in continuous processes. We have perfected this method into an extremely...

Open the catalog to page 11

SensoTech GmbH Steinfeldstraße 1 39179 Magdeburg-Barleben Germany +49 39203 514 100 info@sensotech.com www.sensotech.com SensoTech Inc. 69 Montgomery Street, Unit 13218 Jersey City, NJ 07303 USA +1 973 832 4575 sales‑usa@sensotech.com www.sensotech.com SensoTech (Shanghai) Co., Ltd. Room 609, Bldg.1, No.778, Jingji Road. Pilot Free Trade Zone, 201206 Shanghai China +86 21 6485 5861 sales-china@sensotech.com www.sensotechchina.com LSM007_01_18

Open the catalog to page 12All SensoTech catalogs and technical brochures

-

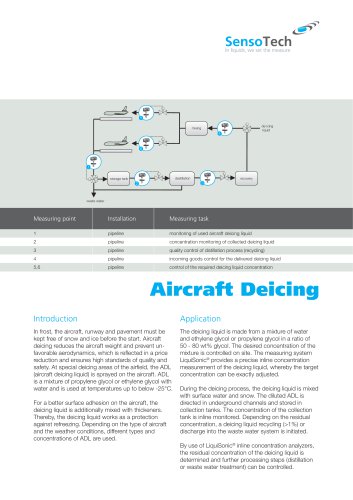

Aircraft Deicingy

3 Pages

-

Company Profile

8 Pages