Inline analytical technology for the metal industry: monitoring of pickling and chrome plating baths, emulsion control, monitoring of acid regeneration and electrolytic galvanizing

1 /

16Pages

Catalog excerpts

Steel and rolling mills Inline analytical technology for: • monitoring of pickling bath • acid regeneration • emulsion control • electrolytic galvanizing • roller chrome

Open the catalog to page 1

Increase quality, save resources: LiquiSonic®. With high-quality, innovative sensor technology. Robust, precise, user-friendly. LiquiSonic® LiquiSonic® is an inline analytical system for determining the concentration in liquids directly in the production process. The analyzer is also used for phase separation and reaction monitoring. Sensor installation within the product stream means an extremely fast measurement that responds immediately to process changes. User benefits include: • • • • • • • • optimal plant control through online and real-time information about process states maximized...

Open the catalog to page 2

Inline process analysis Inhalt LiquiSonic®2 Processes4 Introduction4 Pickling5 Acid regeneration Cold rolling Reversing mill Tandem mill Electrolytic galvanizing Roller chrome plating Further applications LiquiSonic® System Software SonicWork

Open the catalog to page 3

Processes Introduction In the steel production, the LiquiSonic® measuring technology is used in numerous process levels to optimize operations. With this technology it is possible to save process chemicals, such as acids and cooling lubricants without influencing the surface finish negatively. Thus, the online measuring technology ensures a permanent and consistently high quality of products. In the following, applications in pickling bath and cold rolling processes are demonstrated as examples, whereas related measuring tasks are used in further processes. Regarding the measuring...

Open the catalog to page 4

Pickling Pickling baths are used downstream of the hot rolling process, but also in many other fields of the metal-working industry to remove, modify, passivate or clean surfaces in a defined manner. To this end, pickling solutions are employed, mainly consisting of a mixture of mineral acids. The concentration of these acids decreases during the pickling process, whereas the portion of disturbing components such as contaminations and carry-over increases. Pickling process The LiquiSonic® measuring technology provides a solution for online measurements of pickling bath concentrations...

Open the catalog to page 5

Acid regeneration Cold rolling In the regeneration, the used pickling acid is refreshed and removed from contaminations such as iron salt. The type of the procedure depends on the respective used pickling acid. A very known procedure is the crystallization for the recovery of sulfuric acid as well as the spray roasting or buttering-floating procedure for the recovery of hydrochloric acid. A further procedure, which is used for mixed acids, is the dialysis, but also ion exchangers are employed. During the cold rolling process (40 and 70 °C), the thickness of the rolling stock will be...

Open the catalog to page 6

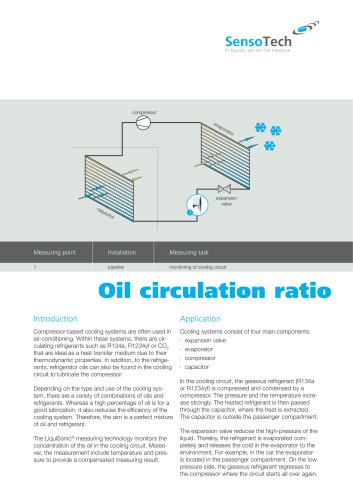

Reversing mill In reversing mills, the rolling oil will run for several times through the mill (passes). This is beneficial for production plants with low capacity and for having of a better microstructure. Tandem mill The tandem mill is used in larger production plants, as the metal strip is running continuously to ensure a higher throughput. By using different emulsion concentrations an optimal surface finish can be guaranteed. Application area of LiquiSonic® at the reversing mill Application areas of LiquiSonic® at the tandem mill Measuring point Measuring task monitoring of rolling...

Open the catalog to page 7

Electrolytic galvanizing In order to modify the surface of steel concerning properties, such as corrosion resistance, it is required to galvanize the steel. There are different possibilities, such as electrolytic galvanizing or hot galvanizing. The ultrasonic measuring technology has been established particularly in the continuous electro-galvanizing to achieve layer thickness from 2.5 to 7.5 µm. By means of direct current in an aqueous solution, the steel strip is coated with zinc from 18 to 54 g/m2. The electrical fields of the zinc bath have no influence on the measuring technology. When...

Open the catalog to page 8

Roller chrome plating Further applications There are different methods of the plating process for working and skin pass rolls, which are used for the forming process in the steel industry. By performing these plating processes, the roll surface becomes harder and the wear can be reduced. Beside this, it is also possible to generate targeted surface structures of rolls, which cause optimal embossing characteristics on the roll product. This is important for downstream processes like galvanizing or painting of the roll product to ensure excellent adhesive properties. In the forming process,...

Open the catalog to page 9

LiquiSonic® System LiquiSonic® 30 The LiquiSonic® system consists of one or more sensors and the controller. The ultrasonic sensor includes the measuring path as well as the highly precise temperature detection. The controller 30 is a highly efficient device that manages up to four sensors. These sensors can be installed in different stages of the tandem mill. Even in reversing mills, it is also possible to operate several sensors with one controller, as the maximum distance between controller and sensor is 1000 m. Controller with connection of maximum four sensors Each sensor works...

Open the catalog to page 10

LiquiSonic® 40 The LiquiSonic® 40 analyzer enables the concentration measurement in 3-component liquids. Thus, it is possible, for example, to determine the concentration of the pickling solution and of the salt in a pickling bath separately. The measuring principle is based on the different effects exerted by changing concentrations of a liquid‘s individual components on physical variables such as sonic velocity, conductivity and density. These features are stored as a calculation model in the evaluation unit (controller) to convert physical variables into concentrations. For pickling and...

Open the catalog to page 11

Accessories In order to install the LiquiSonic® systems appropriately and to facilitate the integration into the respective Process Control System, we offer individual possibilities. The following additional products have proven to be beneficial in the steel production. Plastic housing The controller is designed for rack-mounted systems. In order to be able to mount the controller into the field, the plastic housing is available, which comply with on-site conditions in an optimal way. The controller supports different fieldbus systems and follows the standards recommended by the respective...

Open the catalog to page 12All SensoTech catalogs and technical brochures

-

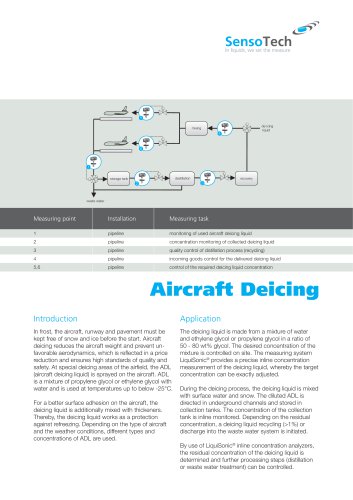

Aircraft Deicingy

3 Pages

-

Company Profile

8 Pages