Inline analytical technology for crystallization monitoring: saturation degree, supersaturation, crystal content, metastable range and particle size

1 /

16Pages

Catalog excerpts

Crystallization monitoring Inline analytical technology for • saturation degree • supersaturation • crystal content • metastable range • partic

Open the catalog to page 1

Increase quality, save resources: LiquiSonic®. With high-quality, innovative sensor technology. Robust, precise, user-friendly. LiquiSonic® LiquiSonic® is an inline analytical system for determining the concentration in liquids directly in the production process. The analyzer is also used for phase separation and reaction monitoring. Sensor installation within the product stream means an extremely fast measurement that responds immediately to process changes. User benefits include: • optimal plant control through online and real-time information about process states • maximized process...

Open the catalog to page 2

Inline process analysis Content LiquiSonic®2 Fundamentals of crystallization Supersaturation8 Supersaturation decreasing and crystal growth kinetics Crystal content

Open the catalog to page 3

Fundamentals of crystallization Sonic velocity measurement is used to determine crystallization parameters and to control crystallization processes. This measuring method enables the detection of the nucleation and saturation point and thus the metastable range. During the crystallization, it is possible to measure the difference to the saturation (degree of saturation), the degree of supersaturation or the crystal content, using as a control variable for influencing the crystallization. When a solid substance is dissolved in a liquid, the liquid is absorptive up to a certain concentration....

Open the catalog to page 4

Processes Crystallization processes in continuous as well as in batch processes can be monitored by measuring the sonic velocity with the LiquiSonic® system. In case of failures or deviations from the process flow, it can easily be reacted to achieve the required product quality. In most cases, the characteristic process flow, which results into an optimal reaction course and thus to the required features of the end-product, is determined by a preliminary investigation. This ideal course can be implemented as so-called “fingerprint” of the process within LiquiSonic® 50. The following...

Open the catalog to page 5

Applications Crystallization parameters Sonic velocity and temperature are measured during cooling and heating the solution to establish the relevant parameters within the process. The sonic velocity presented as a function of the temperature, important crystallisation parameters, such as saturation temperature, nucleation temperature, and the position in the metastable range can be directly determined. The following diagram describes crystallization characteristics like ammonium sulphate with 42.6 w% during heating and cooling at different temperatures. The diagram provides an explanation...

Open the catalog to page 6

Degree of saturation Online measurement of the degree of saturation is based on saturation concentrations varying at different temperatures.The following diagram shows exemplary the saturation behaviour of a large crystallization process. The current concentration is determined by sonic velocity and temperature measurement, and is provided as the saturation difference (degree of saturation) for downstream process control. Via the temperature this control variable serves to advance the process quickly to the stage of saturation to save time and energy. Therefore the process is individually...

Open the catalog to page 7

Supersaturation The degree of supersaturation can also be determined by sonic velocity, as a function of the temperature. As shown in the figure below the degree of supersaturation reflects a specific point within the metastable range. The closer this point is to the nucleation curve, the higher is the degree of supersaturation. When the solution approaches the upper limit of the metastable range (supersaturation 2), the risk is high that it can result into spontaneous nucleation of a too fine end product. However, if the crystallization is too close to the saturation curve (supersaturation...

Open the catalog to page 8

Supersaturation decreasing and crystal growth kinetics The degree to which supersaturation is decreasing during crystallization can be represented as a function of time (supersaturation decline curve). The following diagram shows different crystal growth kinetics which were detected by decreasing of sonic velocity as well as by supersaturation The crystal growth kinetics can be determined from the supersaturation decline curve. This variable indicates how fast the crystals grow in the mother solution and is therefore an important variable for designing and dimensioning crystallizers. As it...

Open the catalog to page 9

Crystal content Each suspension is characterised by a specific sonic velocity behaviour depending on temperature and concentration. The corresponding characteristic curves are also stored in the LiquiSonic® system. This enables the direct inline measurement of the solid concentration respectively crystal content or dry matter content. It is possible to monitor and control the separation in continuous crystallization processes by determining the crystal content. In batch processes the end point of crystallization and the crystal growth can be determined and monitored. Sonic velocity...

Open the catalog to page 10

Accessories There are several possibilities to install the LiquiSonic® analyzer appropriately and to facilitate the integration into the process control system. The following products have proved to be useful. Controller and field housing The controller is designed for rack-mounted systems. It is alternatively available with a 19“ housing 4 HU. In order to be able to mount the controller into the field, two variants of field housings made of plastic or stainless steel can be delivered, which meet on-site conditions in an optimal way. • material: anodized aluminum • dimensions: 482.9 (19“) x...

Open the catalog to page 12

Network integration The LiquiSonic® controller has an Ethernet interface, that makes the integration into the corporate network possible. After entering the user name and password, the access to the stored logs is possible. Integrating the controller into the network enables remote control, view of status information, transfer of product data sets or calibration of products. The Network integration includes • • • • • web server (HTTP), command line (TELNET), file transfer (FTP), time synchronisation (NTP), e-mail notification (SMTP).

Open the catalog to page 13All SensoTech catalogs and technical brochures

-

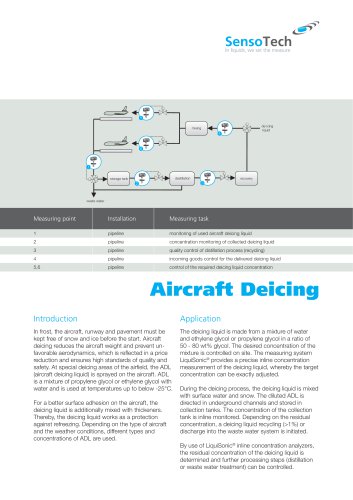

Aircraft Deicingy

3 Pages

-

Company Profile

8 Pages