Website:

SensoPart Industriesensorik GmbH

Website:

SensoPart Industriesensorik GmbH

Catalog excerpts

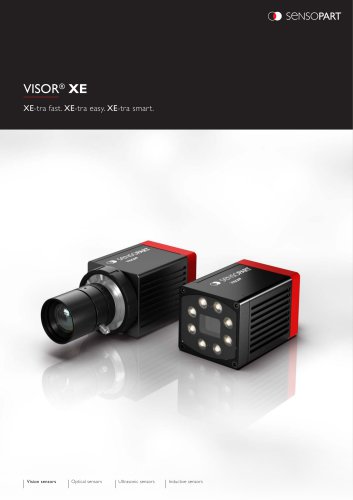

VISOR® Product Overview VISOR® vision sensors for factory automation Vision sensors Optical sensors Ultrasonic sensors Inductive sensors

Open the catalog to page 1

VISOR® vision sensors for factory automation Image processing can be so easy. In the global automation of industrial processes, a vast number of decisions have to be made every second. Here, however, more complex links of detector results are necessary to achieve a safe and reliable good/bad decision. With our portfolio of vision solutions, we cover a wide spectrum of industrial image processing. Now even more complex applications can be evaluated with an easy-to-use vision sensor and without the need for a PC during operation. Whether detection & inspection, identification, measurement,...

Open the catalog to page 2

In many industries and applications the VISOR® can help to achieve the requirements of the automation task: Automotive industry Assembly & Handling Food & Beverages Plastics technology Pharmaceuticals & Cosmetics Solar industry Packaging technology The VISOR® helps to ensure quality, increase plant efficiency, reduce scrap, and reduce costs. The VISOR offers multiple ranges of integrated detectors and functionalities depending on the task: Standard: Solves simple image processing tasks Advanced: An extended scope of functions for more challenging applications Professional: The complete...

Open the catalog to page 3

VISOR® vision sensors One camera, one software, any application Detection & inspection Reliable detection in any situation Most production lines require assembly and quality control checks. The VISOR® Object provides the answer to the most important questions that arise: ▪ Is the object present and correct? ▪ Is it the correct type / object? ▪ Is the object in the right place? ▪ Is the number of objects correct? ▪ Is the object dimensionally accurate? ▪ Is it free of errors? ▪ Does it have the right color? ▪ VISOR® Object Standard - The standard for reliable object detection - 7 detectors...

Open the catalog to page 4

Reliable differentiation and tracking of objects Reliable detection of any position Parts are generally labelled with one-dimensional barcodes or two-dimensional data matrix codes, which are either printed or applied using dot-peen or laser marking technology (direct marking). Our VISOR® Code Readers reliably read all industry standard code types. The precise positioning of parts is a key process in industrial production. Our vision sensors always have an eye on the exact position, and supply the values in robot coordinates in a few simple steps. ▪ VISOR Code Reader - Accurately reads all...

Open the catalog to page 5

Setup requires just a few simple steps Complex tasks made easy - with VISOR® software packages Unpack, set up, go Vision sensors have never been as easy and intuitive to use despite unprecedented levels of performance. Our VISOR® vision sensors are the perfect solution for both beginners and experts. The VISOR® is ready in just a few mouse clicks. Thanks to VISOR® technology from SensoPart, there is now a simple and effective solution for even the most challenging vision tasks. Whether these involve complex object shapes, color detection, data matrix codes, fluorescent display elements –...

Open the catalog to page 6

SensoConfig Complex inspection tasks can be easily set up in a step by step process. The effect of each setting is immediately visible on the screen. Comprehensive logic functions enable the direct assignment of complex inspection results to one of six digital result outputs. The integrated image recorder, which enables error analysis and simulations, is also very useful. SensoView & SensoWeb Once configuration has been completed, the vision sensor operates as a free-standing unit – i.e. without a PC connection. Data can of course be called up at any time while the sensor is running: a...

Open the catalog to page 7

VISOR® Object Standard The standard for reliable object detection HIGHLIGHTS VISOR ® OBJECT STANDARD ▪ Seven detectors for solving presence inspection, completeness inspection or part differentiation tasks ▪ Robust contour alignment for the compensation of position deviations even with non-precisely guided components ▪ Extensive logic functions, flexible result delay of the switching outputs for easy integration into the system The right color in the right place? The Color variant detects different colors faster and more reliably than the human eye. This makes it possible, for example, to...

Open the catalog to page 8

The right package for your individual application: VISOR® Object Standard: Presence and completeness check, sorting of parts ▪ Easy-to-use configuration and viewer software ▪ Easy integration with three field-of-view options and an electrical focus ▪ Trigger signal input delay, output signal delay, and 300mA output control can eliminate the need for a PLC in conveyor and vibratory bowl feeder applications ▪ Reduces setup and maintenance requirements

Open the catalog to page 9

VISOR® Object Advanced Challenging inspection tasks simply solved HIGHLIGHTS VISOR ® OBJECT ADVANCED ▪ All functions of the VISOR® Object Standard ▪ Hardware variants up to 5 megapixels for highest accuracy or largest fields of view ▪ Additional detectors for counting and evaluating objects, as well as for solving measuring and positioning tasks ▪ Three position alignment systems for compensation of position variations even with non-precisely guided components The one with a BLOB: With the BLOB detector (Binary Large Object), the VISOR® detects even small differences between objects, counts...

Open the catalog to page 10

The right package for your individual application: VISOR® Object Advanced: Presence and completeness check, position control, counting of objects, sorting of parts, part recognition and differentiation, simple measuring and quality control tasks. ▪ Reliable detection and evaluation via 12 flexible detectors ▪ Simple compensation of position variations even with components that are not precisely guided ▪ Differentiation of color nuances and compensation of variances via image pre-processing ▪ Trouble-free integration in any installation situation thanks to various resolution levels from 0.5...

Open the catalog to page 11All SensoPart Industriesensorik GmbH catalogs and technical brochures

-

BlueLight - The NEW standard

12 Pages