Catalog excerpts

Komponenten GmbH A-4801 Tr aunkir chen, Hessenber g 1 Tel.:++43(0)7617-3304 Fax:3305 Mail: komponenten@sema.at www.sema.at S NIT EU DL Foto: Schloss Ort - Salzkammergut A STRONG PARTNER IN A STRONG AREA

Open the catalog to page 1

SEMA Maschinenbau GmbH SEMA Komponenten GmbH W e wa n t t o s h a r e o u r k n o w l e d g e a n d o u r e x p e r i e n c e , i n t h e meantime, of thousands of applications in hundreds of m a c h i n e s wi t h y o u . T h e r e f o r e w e wo u l d l i k e t o p l a c e o u r s e l f - m a d e c o m p o n e n t s of our building block system for your individual applications at your disposal. Our high demands on our moduls, like reliability high service life high quality (ISO 9001) high productive power stable construction f l e xi b l e s o l u t i o n s f o r f l e x i b l e o p e r a...

Open the catalog to page 2

SPINDLE UNITS - SE-F FOR DRILL-, MILL-, SAW- AND TURN- PROCESSING stable con struction wit h harden ed and groun d spindle high precision speed range up to 15.000 rpm po wer up to 50 kW spindle with 2 beari ngs wi th 5 spindle-beari ngs l i feti me l ubri cation spi ndl e beari n gs labyrinth seal with stop-air conne ction variable belt box position vari abl e dri ve-trans mi s si on rati o auto mati cal tool change possible by pneumati c or hydraulic operation internal coolant transport or minimum lubrication possible exact mo unting and ad ju stment b y fle xural grooves (feather keys)...

Open the catalog to page 3

SPINDLE UNITS - SE-G FOR DRILL-, MILL-, SAW- AND TURN- PROCESSING stable con struction wit h harden ed and groun d spindle high precision speed range up to 15.000 rpm po wer up to 50 kW spindle with 2 beari ngs wi th 5 spindle-beari ngs l i feti me l ubri cation spi ndl e beari n gs labyrinth seal with stop-air conne ction variable belt box position vari abl e dri ve-trans mi s si on rati o auto mati cal tool change possible by pneumati c or hydraulic operation internal coolant transport or minimum lubrication possible exact mo unting and ad ju stment b y fle xural grooves (feather keys)...

Open the catalog to page 4

SPINDLE UNITS - SE-P FOR DRILL-, MILL-, SAW- AND TURN- PROCESSING stable con struction wit h harden ed and groun d spindle high precision speed range up t0 15.000 rpm po wer up to 50 kW spindle with 2 beari ngs wi th 5 spindle-beari ngs l i feti me l ubri cation spi ndl e beari n gs labyrinth seal with stop-air conne ction variable belt box position vari abl e dri ve-trans mi s si on rati o auto mati cal tool change possible by pneumati c or hydraulic operation internal coolant transport or minimum lubrication possible exact mo unting and ad ju stment b y fle xural grooves (feather keys)...

Open the catalog to page 5

FACING UNITS - PDE - F FOR THE TURNING PROCESSING OF COMPLEX WORKSPIECES stable construction for each range of application high precision CNC or hydraulic-controlled facing head facing heads with automatical tool changing possible speed range up to 8.000 rpm power up to 50 kW spindle with 2 bearings with 5 spindle bearings lifetime lubricated spindle bearings labyrinth seal with air-stop connection variable belt box position and feed-drive arrangement variable drive-tranmission ratio central lubrication for feeding drive of the facing head is intended internal lubrication stuff supply for...

Open the catalog to page 6

FOR THE TURNING PROCESSING OF COMPLEX WORKSPIECES stable construction for each range of application high precision CNC or hydraulic-controlled facing head facing heads with automatical tool changing possible speed range up to 8.000 rpm power up to 50 kW spindle with 2 bearings with 5 spindle bearings lifetime lubricated spindle bearings labyrinth seal with air-stop connection variable belt box position and feed-drive arrangement variable drive-tranmission ratio central lubrication for feeding drive of the facing head is intended Interna l lubrication stuff supply for the automatical lub...

Open the catalog to page 7

FOR INDIVIDUAL PROCESSING POSSIBILITIES by servo transmitter or measuring system 0,005 mm bis 300 mm / 0,01 mm bis 3.000 mm positioning accuracy Technical Data most differen t types, flexible arra nge ment stable con struction wit h harden ed and ground rol ler gui de way s. high precision and load capacity feeding speed up to 60 m/min drive by AC-servomotor and rollerballspindle or hydraulic cylinder variable belt box position vari abl e dri ve trans mi ssion r ati o central lubrication point for rollerballspindle, bearing and guidewagon is intended optionaldelivered with sli dewa y...

Open the catalog to page 8

FOR INDIVIDUAL PROCESSING POSSIBILITIES by servo transmitter or measuring system 0,005 mm bis 300 mm / 0,01 mm bis 3.000 mm positioning accuracy Technical Data most differen t types, flexible arra nge ment stable con struction wit h harden ed and ground rol ler gui de way s. high precision and load capacity feeding speed up to 60 m/min drive by AC-servomotor and rollerballspindle or hydraulic cylinder variable belt box position vari abl e dri ve trans mi ssion r ati o central lubrication point for rollerballspindle, bearing and guidewagon is intended optional del i vered wi th sli deway wi...

Open the catalog to page 9

stable con struction wit h harden ed and ground rol ler gui de way s high precision and load capacity feeding speed up to 60 m/min drive by AC-servo-motor and roller ball spindle or hydraulic cylinder variable belt box position vari abl e dri ve-trans mi s si on rati o central lubrication point for rollerballspindle, bearing and guidewagon is intended optional delivered with sli deway wipers , bello w or telescopic covers exact mo unting and ad ju stment of constru ctional units by flexural groo ves (feather keys) constru cted for the asse mbly with SEMA ma chining units H2 Technical Data...

Open the catalog to page 10

self-centering vice with syncron crank system high clamping force by hydraulic clamping high precision and repetitive accuracy stripping system against dust and dirt additional air-stop connection possible central lubration point for clamping jaws possible exact mounting and adjustment by feather key groove short opening and closing times harded chlanging jaws as mould clamping jaws or prisms clamping jaws hydraulik cylinder working pressure repetitive accuracy by multi-limit-switch or measuring system Technical Data clamping force opening/closing time

Open the catalog to page 11All SEMA Maschinenbau GmbH catalogs and technical brochures

-

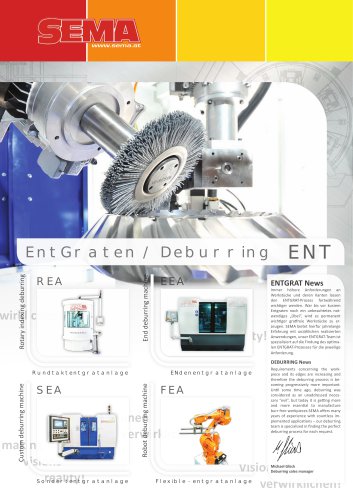

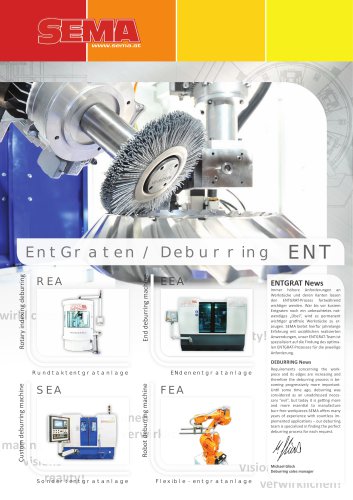

SEMA deburring

8 Pages

-

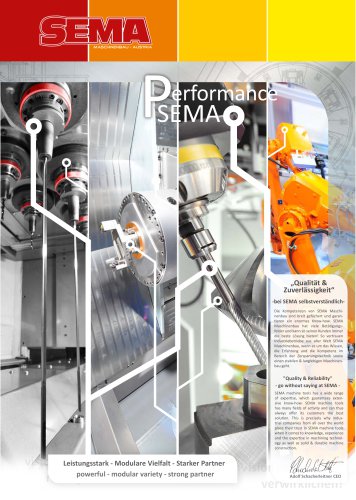

SEMA Performance

11 Pages

-

SEMA automation

5 Pages

-

SEMA components brochure

12 Pages

-

SEMA Automotive Car & Truck

5 Pages

-

SEMA_HDC-Folder-Ausgabe7

2 Pages

-

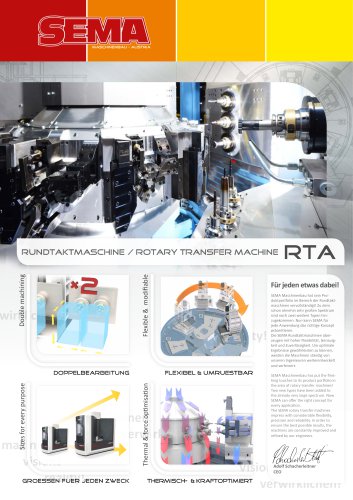

rotary transfer machine

7 Pages

-

deburring

8 Pages

-

SEMA Processing Plants

8 Pages