Catalog excerpts

This machine is designed to carry out the automatic demoulding of pralines or bars that are held inside moulds The production rate of this machine is 4 moulds per minute It can, as an option, be loaded manually but it achieves a very high performance and productivity rate if combined with the SPIDER cooling tunnel. The moulds are automatically demoulded onto a rigid surface at the exit of the tunnel, hence avoiding manual intervention from the operator. The mat will carry the product to the wrapping machine or to the packaging line. The machine needs to be connected to compressed air with a pressure of 6 BAR and 100 litres/minute. automatic demoulder Technical data Electrical specification: 230 V single phase – 50 Hz Required power: 1.5 kW – 16 A – 3 poles Optimal operating temperature: 20/25°C , maximum 32°C Dimensions: h. 1300, w. 1900, d. 1100 mm

Open the catalog to page 1All Selmi catalogs and technical brochures

-

OneShotTuttuno9

1 Pages

-

dataSheetMouldingLine 275

1 Pages

-

dataSheet RS200 Coating Belt

1 Pages

-

Winnower

1 Pages

-

Tunnel 600/800/1200

1 Pages

-

Moulding line 275

1 Pages

-

Mould loader 175

1 Pages

-

Tank 200

1 Pages

-

Chocoform

2 Pages

-

Comfit

2 Pages

-

Filler praline

1 Pages

-

Filler vasi

1 Pages

-

Micron 25

1 Pages

-

Oneshot

2 Pages

-

Cento

1 Pages

-

Truffle

1 Pages

-

Colatore

1 Pages

-

Micron

1 Pages

-

Macchia

1 Pages

-

Roaster 101

1 Pages

-

Roaster 102

1 Pages

-

Roaster 106

1 Pages

-

Roaster 120

1 Pages

-

Top EX

1 Pages

-

Futura EX

1 Pages

-

Plus EX

1 Pages

-

Color EX

1 Pages

-

R200 Legend

1 Pages

-

Legend

1 Pages

-

Selmi One

1 Pages

-

Tuttuno

1 Pages

-

roster 20

1 Pages

Archived catalogs

-

Micron 50

1 Pages

-

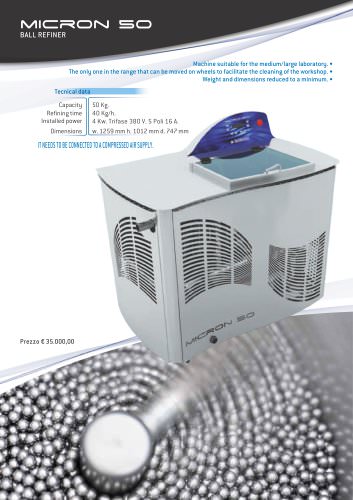

Micron 50 BALL REFINER

1 Pages