Catalog excerpts

flexi line

Open the catalog to page 1

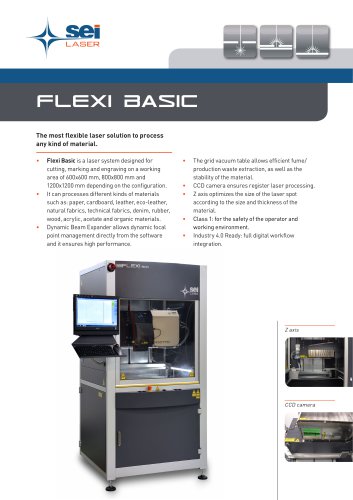

We have been a solid industrial reality, leader in laser technology since 1982. We are the ideal partner at the service our customers, offering them innovative solutions able to fulfit the specific requests of the reference market. Thanks to our know-how and continuous investments, we supply laser systems that ensures significant performances in terms of costs, operational efficiency and quality of the product. The complete laser systems range, developed by our R&D department, creates value and meets our customers application needs.

Open the catalog to page 2

THE LASER WAY We have been producing our laser systems in Italy since 40 years thanks to our five departments (mechanical, electronic, optoelectronic, IT and production) that follow all development process stages. SEI Laser systems are controlled by software and firmware developed internally, by a team of expert programmers able to respond promptly to the various application needs. Cutting-edge technologies require commitment and constant research: our history has its cornerstones in loyalty and mutual esteem with customers. This alchemy has allowed us to establish professional and solid...

Open the catalog to page 3

SEI Laser, the leading Italian industrial laser systems manufacturer, presents Flexi 6/8/12 xx, the innovative and flexible laser systems range, specifically designed to meet all customer’s needs thanks to its configurations. Available in over 30 models and equipped with laser power sources from 150 to 500W, it allows the plate processing. Flexi 6/8/12xx allows marking, surface engraving, micro-perforation and cutting of sheet materials.

Open the catalog to page 5

Flexi T is the “top of the range” professional laser system for marking and engraving of sheet materials and both cutting and half-cutting of sheet materials. working area mobile worktop Flexi T is equipped with a mobile worktop for processing materials larger than the working area. The machine high accuracy and repeatability are combined with the top of the sector galvanometric head dynamic performances: the maximum speed is over 15000 mm/s and the acceleration easily overcomes 10 g. The machine extremely rigid solid structure, in electro welded steel, combined with the movement of the...

Open the catalog to page 6

working area In some machine configurations this operating mode is available as standard. Flexi TT represents a specific operating mode, that thanks to a particular software configuration, allows to use the machine worktop in pendular mode in order to optimize the loading / unloading material time and increase the machine productivity.

Open the catalog to page 7

working area double worktop Flexi 2T, with double table configuration, allows also to work on-the-fly mode on one table and carry out loading and unloading operations in masked time at the same time on the other table, guaranteeing higher productivity without downtime, always in maximum safety.

Open the catalog to page 8

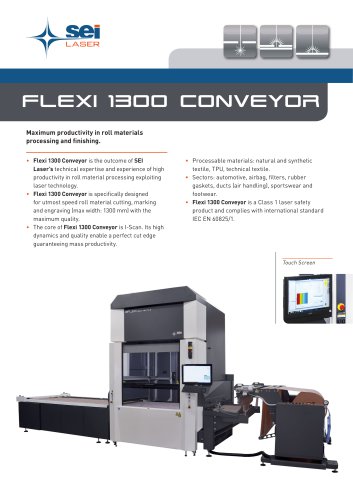

Flexi 1300 conveyor is the professional laser system that guarantees the maximum productivity processing, roll materials finishing and micro-perforation. The Flexi 1300 conveyor system is specifically designed to cut, mark and engrave roll materials with a maximum width of 1300 mm and with a productivity up to 10 times higher than traditional and existing laser technologies, maintaining the highest quality. working area The transport conveyor, specially developed for laser processing, allows extremely accurate creations and exceptional cutting quality.

Open the catalog to page 9

• Easy use. • High process speed and productivity. • Top sector performances thanks to the equippd linear motors and the control algorithms developed by SEI Laser. • Very low maintenance, robustness and laser source long life. • Electronic Z-axis to optimize the working area and the laser spot. • Various configurations that make the system suitable for any environment and production process. • Industry 4.0 ready: simple insertions into digitized and automatic workflows. • 100% made in Italy.

Open the catalog to page 10

• Protection cabin for maximum safety, in compliance with current regulations. • Complete range of scanning heads available Hi30 Hi50 I-scan. • Worktop movement controlled by high precision optical strips to work “on the fly". • Extremely robust electro-welded steel frame. • Class 1 for operator safety. • Icaro software proprietary, intuitive and user friendly.

Open the catalog to page 11

FLEXIBILITY The various FLEXI LINE available configurations make the system suitable for any environment and production process. • CCD camera for laser cutting in register and for automatic work files upload, thanks to the 2D and 3D codes reading. • Smoke aspiration optimized also for “on the fly" processes. • Customizable worktop to adapt to all kind of workings. • Special Hardware/Software configuration for highspeed “on the fly" processes (with micrometrical precision).

Open the catalog to page 13

PROCESSABLE MATERIALS Flexi Flexi Line is able to process countless organic and composite materials in sheet or roll format. Plastic Materials: Acrylic (PMMA) Acrylonitrile Butadiene Styrene (ABS) Composite materials Acetates Plastic laminated films Adhesive film Polyamide (PA) Polybutylene terephthalate (PBT) Polycarbonate (PC) Polyethylene (PE) Polyester (PES) Polyethylene terephthalate (PET) Polyimide (PI) Polypropylene (PP - BOPP) Polyphenylene Sulfide (PPS) Polystyrene (PS) Polyurethane foam (PUR) Foam (PVC free)

Open the catalog to page 14

Natural fibers (e.g. cotton, linen) Synthetic fabrics Technical fabrics Foils Wool Silk Kevlar Fabrics: Polyester (PES) Felt Microfiber Leather Skin Synthetic leather Other materials: Wood Paper Cardboard Cork Glass Rubber MDF

Open the catalog to page 15

APPLICATIONS The various configurations available make the Flexi LINE system extremely flexible, perfect to meet any application need. Objects, furnishing accessories (customization), decoration, inlay, stamps, exhibitors, footwear sector, leather processing, processing of sheet and / or roll materials,

Open the catalog to page 16

lighting engineering, electronics, backlight, automotive sector, eyewear, flags and banners, signage, sportswear, packaging.

Open the catalog to page 17All SEI LASER catalogs and technical brochures

-

Wood ITA-ENG - brochure

28 Pages

-

Visual Communication - brochure

24 Pages

-

Shrink Sleeve - Brochure

2 Pages

-

Plastic ITA-ENG - brochure

24 Pages

-

Matrix Textile - brochure

8 Pages

-

Labels & Converting - brochure

16 Pages

-

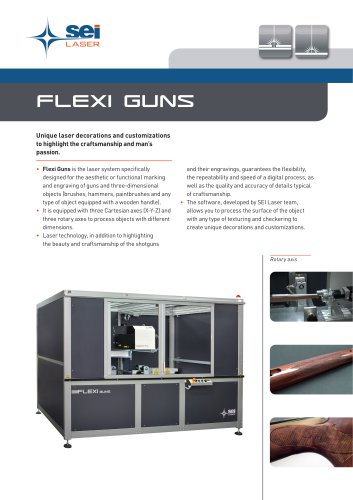

Guns - brochure

12 Pages

-

Flexible Packaging - brochure

16 Pages

-

Denim & Fashion - brochure

16 Pages

-

Backlight - brochure

16 Pages

-

Origami - technical sheet

2 Pages

-

Easy Fiber - technical sheet

2 Pages

-

NRGL - technical sheet

2 Pages

-

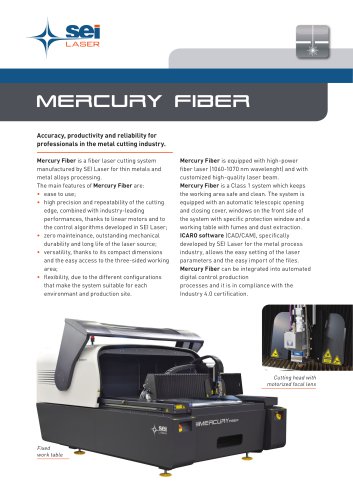

Mercury Fiber - Brochure

28 Pages

-

H-Type - technical sheet

2 Pages

-

Dragon - technical sheet

2 Pages

-

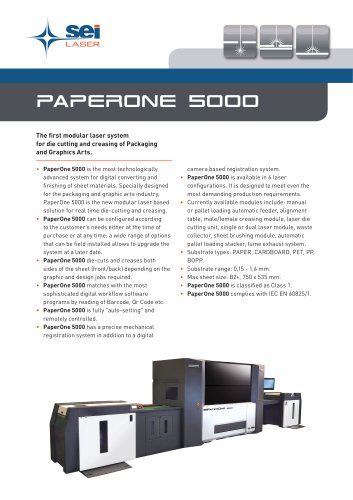

PaperOne 5000

2 Pages

-

PackMaker

4 Pages

-

Manta - technical sheet

2 Pages

-

Infinity Line - brochure

2 Pages

-

Flexi Guns - technical sheet

2 Pages

-

X-Type - technical sheet

2 Pages

-

Mercury Line - brochure

28 Pages

-

Eureka - technical sheet

2 Pages