Website:

Seaward

Website:

Seaward

Group: Seaward Electronic Ltd.

Catalog excerpts

Seaward, Bracken Hill, South West Industrial Estate, Peterlee, County Durham, SR8 2SW United Kingdom Tel: +44 (0) 191 586 3511 Fax: +44 (0) 191 586 0227 Email: sales@seaward.co.uk Web: www.seaward.co.uk Seaward, Clare, Rigel Medical, Cropico, Seaward Group USA are all part of the Seaward Group Tried. Tested. Trusted. 17th Edition Testing AGuideto This material is for information purposes and as general guidance only. It is not necessarily deemed definitive and is subject to change without notice. Seaward and its associated companies accept no responsibility for any errors or consequential loss or damage which may arise from misinterpretation of the information or procedures. However, every effort has been made to ensure the accuracy of information presented but the reader should refer to manufacturer / supplier data and relevant published standards when producing or using 17th Edition test procedures.

Open the catalog to page 1

02 - 03 The Installation System 04 Introduction 04 - 09 A. Tests before the supply is connected 05 1. Continuity of protective conductors including main and supplementary equipotential bonding 06 2. Continuity of ring final circuit conductors 07 3. Insulation resistance 08 4. Polarity 09 5. Earth electrode resistance 12 - 14 B. Tests with the electrical supply connected 12 1. Earth fault loop impedance 13 - 14 2. RCD testing 14 - 17 Appendix 14 1. Continuity testing 15 - 17 2. Insulation resistance testing 18 - 19 PowerPlus 1557 20 - 21 17th Edition product range Tried. Tested. Trusted....

Open the catalog to page 2

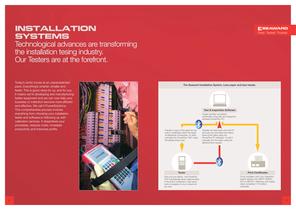

Installation systems Technological advances are transforming the installation tesing industry. Our Testers are at the forefront. 3 Tried. Tested. Trusted. Today’s world moves at an unprecedented pace. Everything’s smarter, smaller and faster. This is good news for us, and for you. It means we’re developing and manufacturing better equipment and we can now help your business or institution become more efficient and effective. We call it PowerSolutions. This comprehensive process involves everything from choosing your installation tester and software,to following up with calibration services....

Open the catalog to page 3

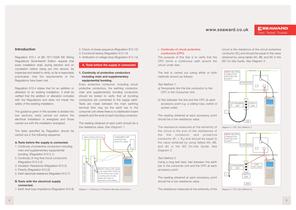

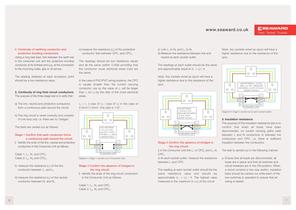

i. Continuity of circuit protective conductors (CPC) The purpose of this test is to verify that the CPC forms a continuous path around the circuit under test. The test is carried out (using either or both methods shown) as follows: Test Method 1: a) Temporarily link the line conductor to the CPC in the Consumer Unit. b) Test between the line and the CPC at each accessory point e.g. a ceiling rose, switch or socket outlet. The reading obtained at each accessory point should be a low resistance value. The resistance measured at the extremity of the circuit is the sum of the resistances of the...

Open the catalog to page 4

ii) Link L1 to N2 and L2 to N1 iii) Measure the resistance between line and neutral at each socket outlet. The readings at each outlet should be the same and approximately equal to (r1 + rn) / 4. Note: Any sockets wired as spurs will have a higher resistance due to the resistance of the spur. Diagram 5: Stage 2 (carried out in Consumer Unit) Stage 3 Confirm the absence of bridges in the ring circuit. i) In the Consumer Unit link L1 to CPC2 and L2 to CPC1. ii) At each socket outlet, measure the resistance between L and CPC. The reading at each socket outlet should be the same resistance...

Open the catalog to page 5

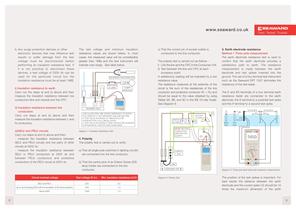

c) That the correct pin of socket outlets is connected to the line conductor. The polarity test is carried out as follows : i) Link the line and the CPC in the Consumer Unit. ii) Test between the line and CPC at each accessory point. A satisfactory reading will be indicated by a low resistance value. The resistance measured at the extremity of the circuit is the sum of the resistances of the line conductor and protective conductor (R1 + R2) and should be equal to the value obtained by using Tables 9A, 9B, and 9C in the IEE On-site Guide. See Diagram 8. Diagram 8: Polarity Test 5. Earth...

Open the catalog to page 6

the current clamp method. Method 3 Earth loop impedance measurement If the earth electrode is used in conjunction with an RCD, the earth electrode resistance can be tested by using the following method. i. Switch off the supply and disconnect the earth electrode from the main earthing terminal. ii. Connect the loop tester between the line conductor at the source and the earth electrode. iii. Perform an earth loop impedance test. The measured value is taken as the earth electrode resistance (RA). iv. Ensure that the supply is then safely isolated BEFORE the earthing conductor is reconnected...

Open the catalog to page 7

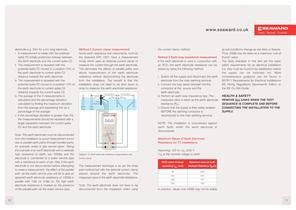

13 Tried. Tested. Trusted. B. Tests with the electrical supply connected 1. Earth fault loop impedance The earth fault loop impedance is given by: Zs = Ze + (R1+R2) The value of Zs can be found by: I. measuring the earth fault loop impedance Zs at the furthest point II. measuring the earth fault loop impedance Ze at the incoming supply and adding (R1+R2). III. taking the earth fault loop impedance Ze provided by the distributor and adding (R1+R2). Diagram 11: Measurement of External Earth Loop Impedance Ze Preparation for the Test 1. Main Switch in the Consumer Unit is switched OFF. 2. Main...

Open the catalog to page 8

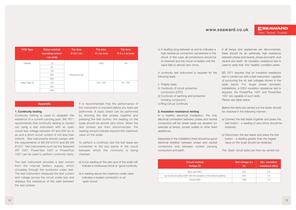

If all lamps and appliances are disconnected, there should be an extremely high resistance between phase and neutral, phase and earth, and neutral and earth. An insulation resistance test is used to verify that this 'healthy' condition exists. BS 7671 requires that an insulation resistance test is carried out with a test instrument capable of producing the dc test voltages shown in the table below. For single phase domestic installations, a 500V insulation resistance test is required. the PowerPlus 1557 and PowerTest 1557 are capable of such tests. Please see table below. Before the tests...

Open the catalog to page 9

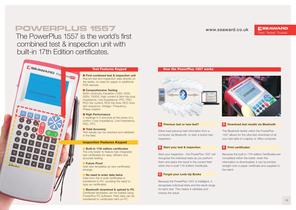

19 Tried. Tested. Trusted. Powerplus 1557 www.seaward.co.uk The PowerPlus 1557 is the world’s first combined test & inspection unit with built-in 17th Edition certificates. Test Features Keypad First combined test & inspection unit Record test and inspection data directly on the tester, no need for paper or additional PDA devices. Comprehensive Testing Earth continuity, Insulation (100V, 250V, 500V, 1000V), High current & Non-trip loop impedance, Line Impedance, PFC, PSC, RCD trip current, RCD trip time, RCD Auto test sequence, Voltage / Frequency, Phase rotation. High Performance 4...

Open the catalog to page 11All Seaward catalogs and technical brochures

-

PV150+

3 Pages

-

Seaward NTB-1

2 Pages

-

D255

2 Pages

-

PrimeTest 100

2 Pages

-

Solar Survey 100/200R Series

4 Pages

-

PrimeTest 50

2 Pages

-

00 Series

2 Pages

-

2018 Seaward PAT Selector

15 Pages

-

Cropico DO4000 Series

2 Pages

-

Cropico DO4A

2 Pages

-

SDR Series

1 Pages

-

Printers and Scanners

8 Pages

-

PR11

2 Pages

-

MTS

2 Pages

-

HAL Series

5 Pages

-

HAL LED

4 Pages

-

CR Series

1 Pages

-

Apollo+ Series

6 Pages

-

Seaward Manufacturing

12 Pages

-

PATGuard 3 PAT Testing Software

153 Pages

-

PrimeTest 250+ PAT Tester

4 Pages

-

Apollo 600

5 Pages

-

PrimeTest 250+

4 Pages

-

Apollo 400

5 Pages

-

Powercheck 1557

2 Pages

-

Power Clamp

3 Pages

-

Apollo 500

20 Pages

-

Cropico RS3 Datasheet

2 Pages

-

Cropico RM6 Datasheet

1 Pages

-

Cropico RBC Datasheet

2 Pages

-

Cropico RBB Datasheet

2 Pages

-

Cropico CM5-N Datasheet

1 Pages

-

Cropico RM8 Datasheet

1 Pages

-

Cropico RM6N Datasheet

1 Pages

-

Cropico DO7010 Datasheet

2 Pages

-

Cropico DO7Plus Datasheet

2 Pages

-

Cropico DO6 Datasheet

2 Pages

-

Cropico DO7E Datasheet

2 Pages

-

Cropico DO7 Datasheet

2 Pages

-

PowerCheck 1557 Datasheet

2 Pages

-

PAT Checkbox Datasheet

2 Pages

Archived catalogs

-

Supernova Elite

2 Pages

-

Seaward Product

72 Pages

-

Powerplus 1557

4 Pages

-

PAT Testing Product

20 Pages

-

Cropico Product

48 Pages

-

ClareHAL

12 Pages

-

Clare Product

28 Pages

-

Calibrationhouse

2 Pages

-

Cropico DP6 Datasheet

2 Pages

-

Seaward PAT Testing Guide

20 Pages

-

Cropico DO5000-CS Datasheet

1 Pages

-

Cropico DO8000 Datasheet

2 Pages

-

Clare G2000 Datasheet

2 Pages

-

Clare B433R Datasheet

2 Pages

-

Clare Elite Datasheet

4 Pages

-

Clare B255 Datasheet

2 Pages

-

PrimeTest 300 Datasheet

2 Pages

-

SEN60204 Datasheet

22 Pages

-

SD 300 Datasheet

2 Pages

-

PrimeTest 250 Datasheet

2 Pages

-

Clare Horizon II Datasheet

2 Pages

-

Clare PowerSmart Datasheet

2 Pages

-

Clare A320 Datasheet

2 Pages

-

Clare Sentinel Datasheet

2 Pages

-

Clare HAL Combi Datasheet

2 Pages

-

Type L Plus Datasheet

2 Pages

-

PowerPlus 1557 Datasheet

2 Pages

-

Proving Units Datasheet

2 Pages

-

PowerGuard Pro Mobile 2

2 Pages

-

PowerGuard Pro 2 Datasheet

2 Pages

-

PATGuard Elite 2 Datasheet

2 Pages

-

Clare A252 Datasheet

1 Pages

-

Halo Hook Datasheet

2 Pages

-

IRT 1557 Datasheet

2 Pages

-

ERT 1557 Datasheet

2 Pages

-

VT800D Datasheet

2 Pages

-

VT800 Datasheet

2 Pages

-

PrimeTest 350 Datasheet

2 Pages

-

PATGuard Pro 2

2 Pages

-

PATGuard Lite 2

2 Pages

-

PATGuard Elements Datasheet

2 Pages

-

Test n Tag Datasheet

2 Pages

-

Supernova Plus Datasheet

2 Pages

-

PowerTest 1557 Datasheet

2 Pages

-

DM800/DM800R

1 Pages

-

Europa Plus PAT Tester

2 Pages

-

Supernova Plus PAT Tester

2 Pages