Website:

SCHWING Technologies GmbH

Website:

SCHWING Technologies GmbH

Group: thermal cleaning

Catalog excerpts

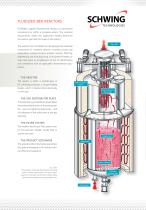

SCHWING supplies fluidized bed reactors as stand-alone The fluidized bed systems from the BSR model Principally, the design of the BSR lab reactors from components or within a complete system. The customer SCHWING corresponds to the reactor construction requirements and/or the application thereby determine the reactor type and the scope of the system. nano-scale powders with reaction gases in atmosphe- FLUIDIZED BED PROCESS TECHNIQUE The systems from SCHWING can be designed as individual shown on the opposite side. In addition, the BSR model series offers the following advantages: Mobile compact design, smallest footprint components or complete systems, including control, gas The BSR systems offer excellent heat and mass transfer preparation, energy recovery, product cooling. Planning, properties at top temperature accuracy for typical ap- Can be used already from 1.5 liters useful volume engineering and manufacturing of all systems thereby al- Advanced, easy to operate process control ways take place in consideration of the CE identification and compliance with all applicable environmental stipu- oxidizing / reducing surface modification through different reaction gases or THE REACTOR The reactor is either a cylinder-type or for continuous process, a trough-shaped mixes from several gases. High temperature reactor design, which is heated either electrically High temperature filter system High temperature reactors for gas / solid reactions up to 1100 °C THE GAS DISTRIBUTOR PLATE The proprietary gas distributor plate allows the optimal distribution of the process gases – even at highest temperatures – and a fluidization of the solids even at low gas velocities. THE FILTER SYSTEM The modern block back filter system retains fine particles. Metallic candle filter or cyclone are used. Fluidized bed Heating room The special product discharge guarantees the optimal emptying of the reactor without affecting fluidization. Product discharge Fig. right: Presentation of the gas flow through the solids inside a fluidized bed reactor. The gas is separated from the solids via the filter candles (blow back) and transported to the preparation unit. Proprietary distributor plate SCHWING Technologies GmbH Oderstrasse 7 · 47506 Neukirchen-Vluyn / Germany Fluidizing gas Phone +49 2845 930-0 E-mail info@schwing-tech.com www.schwing-technologies.com Visit us on:

Open the catalog to page 1

PERFECTED TECHNOLOGY ULTIMATE EFFICIENCY SCHWING LAB+TECH CENTER Based on over 40 years of development, experience and The uniform distribution of the gas in the solids is the es- SCHWING develops, engineers and builds fluidized bed The SCHWING LAB+TECH CENTER is located at the The successful employment or development of a high- success, SCHWING manufactures specific high-tempera- sential prerequisite for good fluidization. The greater the systems both at the bench scale and the production scale company‘s headquarters in Neukirchen-Vluyn (Germany). performance fluidized bed reactor for...

Open the catalog to page 2

SCHWING supplies fluidized bed reactors as stand-alone The fluidized bed systems from the BSR model Principally, the design of the BSR lab reactors from components or within a complete system. The customer SCHWING corresponds to the reactor construction requirements and/or the application thereby determine the reactor type and the scope of the system. nano-scale powders with reaction gases in atmosphe- FLUIDIZED BED PROCESS TECHNIQUE The systems from SCHWING can be designed as individual shown on the opposite side. In addition, the BSR model series offers the following advantages: Mobile...

Open the catalog to page 3

PERFECTED TECHNOLOGY ULTIMATE EFFICIENCY SCHWING LAB+TECH CENTER Based on over 40 years of development, experience and The uniform distribution of the gas in the solids is the es- SCHWING develops, engineers and builds fluidized bed The SCHWING LAB+TECH CENTER is located at the The successful employment or development of a high- success, SCHWING manufactures specific high-tempera- sential prerequisite for good fluidization. The greater the systems both at the bench scale and the production scale company‘s headquarters in Neukirchen-Vluyn (Germany). performance fluidized bed reactor for...

Open the catalog to page 4

PERFECTED TECHNOLOGY ULTIMATE EFFICIENCY SCHWING LAB+TECH CENTER Based on over 40 years of development, experience and The uniform distribution of the gas in the solids is the es- SCHWING develops, engineers and builds fluidized bed The SCHWING LAB+TECH CENTER is located at the The successful employment or development of a high- success, SCHWING manufactures specific high-tempera- sential prerequisite for good fluidization. The greater the systems both at the bench scale and the production scale company‘s headquarters in Neukirchen-Vluyn (Germany). performance fluidized bed reactor for...

Open the catalog to page 5

SCHWING supplies fluidized bed reactors as stand-alone The fluidized bed systems from the BSR model Principally, the design of the BSR lab reactors from components or within a complete system. The customer SCHWING corresponds to the reactor construction requirements and/or the application thereby determine the reactor type and the scope of the system. nano-scale powders with reaction gases in atmosphe- FLUIDIZED BED PROCESS TECHNIQUE The systems from SCHWING can be designed as individual shown on the opposite side. In addition, the BSR model series offers the following advantages: Mobile...

Open the catalog to page 6All SCHWING Technologies GmbH catalogs and technical brochures

-

Schwing Thermal Cleaning

6 Pages

-

INNOVACLEAN

6 Pages

-

VACUCLEAN 0917

1 Pages

-

VACUCLEAN COMPACT

1 Pages

-

VACUCLEAN

6 Pages

-

Fluidized Bed Systems

3 Pages