Catalog excerpts

S 46 SX / S 47 SX Truck-Mounted concrete pump with 4-section placing boom

Open the catalog to page 1

YOUR ENTRY INTO THE LONG BOOM MARKET Super X Outriggers Give You the Edge This open loop Generation 3 all-hydraulic concrete pump sets the standard for fuel-efficiency, reliability and performance. Twin circuit hydraulics combine with the longest stroking pumping cylinders in the industry for a smooth, continuous flow of concrete which also translates to longer boom life. Big Rock Valve is designed to pump the harshest mixes and provide the lowest per yard operating costs. Patented Vector Controls allow two-way communication between pump and operator. Critical real-time operating data is...

Open the catalog to page 2

Separate yourself from the pack and become the leader in your market with these versatile pumps. You will gain additianal 3-feet of boom reach with the optional S 47 SX which has a longer tip section. Both models share the same innovative Overhead Roll and Fold™ boom design that works so well on bridges, commercial and industrial work. Hundreds of pumpers and concrete contractors have discovered the versatility of a boom with a main section that articulates 180-degrees. This feature allows the main section to be angled away from the pour so that the boom can be guided horizontally into...

Open the catalog to page 3

Theor. Concrete Output Per Hour (cubic yards - cubic meters) Maximum Pressure on Concrete (psi - bar) Maximum Strokes Per Minute Material Cylinder Diameter (in. - mm) Material Cylinder Stroke Length (in. - mm) Differential Cylinder Size (in. - mm) Maximum Aggregate Size (in. - mm) Vertical Reach (ft.-in. - m) Horizontal Reach (ft.-in.- m) Net Horizontal Reach (ft.-in. - m) Unfolding Height (ft.-in. - m) Boom Specifications Section Lengths First Section (ft.-in. - m) Second Section (ft.-in. - m) 38 / 38 Third Section (ft.-in. - m) Slewing Range (degrees) Specifications are subject to change...

Open the catalog to page 4

Only one manufacturer can supply the Schwing experience. Thousands of our customers form a backdrop of success that you can join by letting us specify the right piece of equipment for your needs. Technicians and parts placed strategically across the country provide service expertise and support as close as your phone. Our Call Center is staffed by experienced men and women who work with you to satisfy your needs. Join hundreds of owners who have sent their employees to our dedicated training facility to learn how to extract the maximum profitability from a Schwing. And your investment is...

Open the catalog to page 5

on Do not stand hopper grates. SAFETY INSTRUCTIONS BEFORE REMOVING HOPPER GRATE OR PERFORMING ANY SERVICE: Gasoline or Diesel Engines 1. Stop the engine. Electric Motors 1. Stop the electric motor. 2. Remove the key, place it in your pocket, and put a "DO NOT OPERATE" tag on the switch. 2. Lock out the power source according to an approved lockout-tagout program. 3. Check accumulator circuit pressure gauge (if so equipped) to verify zero system pressure. 3. Check accumulator circuit pressure gauge (if so equipped) to verify zero system pressure. SCHWING-STETTER MOVES CONCRETE. WORLDWIDE....

Open the catalog to page 6All SCHWING GmbH catalogs and technical brochures

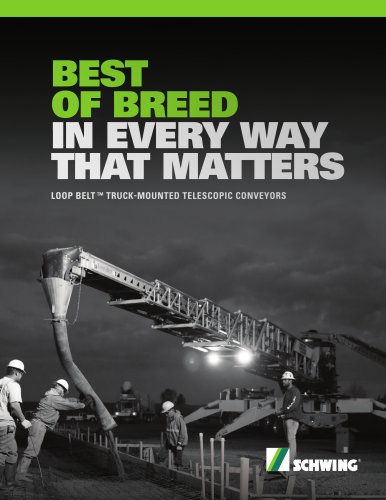

-

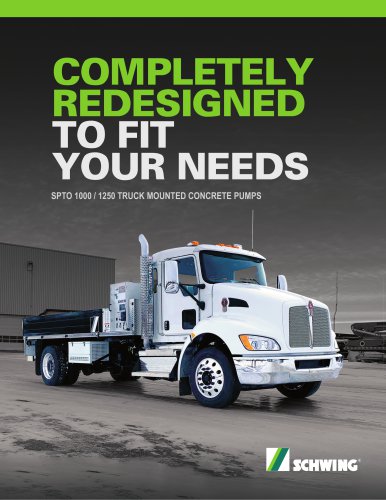

SPTO 1000 / 125

5 Pages

-

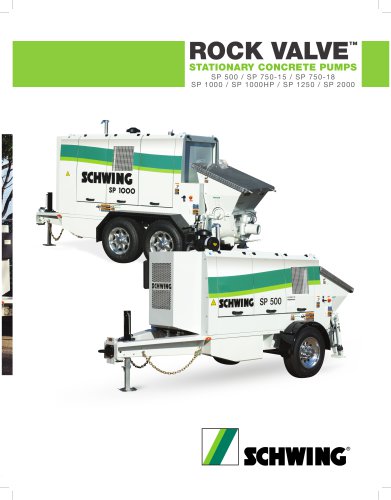

SP 500

8 Pages

-

SP 305

4 Pages

-

S 32 X / S 36 X

6 Pages

-

S 31 XT

4 Pages

-

S 28 X

6 Pages

-

S 20

4 Pages